Pay-off braking device for spindle of high-speed braiding machine

A high-speed knitting machine and braking device technology, which is applied to woven fabrics, textiles and papermaking, can solve the problems of large brake clearance, large brake transmission resistance, and unstable parking, and achieve accurate braking without clearance, high flexibility, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

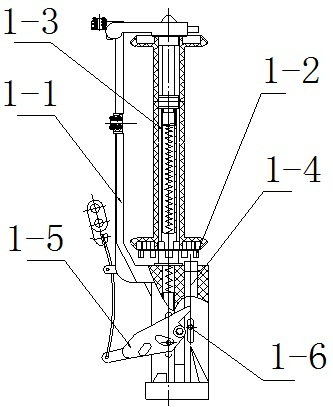

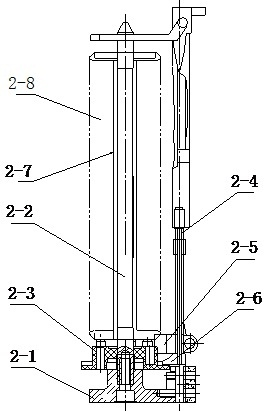

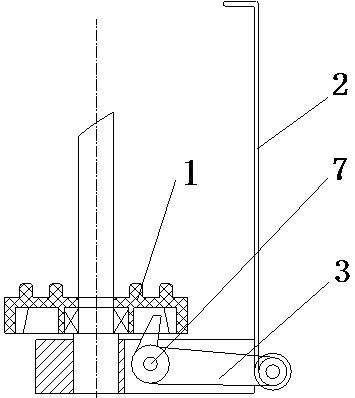

[0021] Embodiment 1: The brake device includes: bobbin seat 1, brake claw 3 and connecting rod 2; one end of brake claw 3 is pressed on the side wall of the inner circular groove under bobbin seat 1, and the other end of brake claw 3 is connected to Connecting rod 2.

[0022] The bobbin seat 1 is disc-shaped, with a hole in the middle of the disc, cylinders are evenly distributed on the circumference of the same center as the central hole, and a circular inner groove is arranged below the disc, and the inner wall of the circular inner groove is Raised tables are arranged.

[0023] The brake claw 3 is "L" shaped, with a pawl-shaped front end, connected to the circular inner groove under the bobbin seat 1, and can move in the circular inner groove, hooking the inner wall or disengaging the inner wall; the brake claw 3 is provided with a small hole at the bending point, and the small hole is sleeved on the fulcrum shaft 7, and the rear end is slidably connected with the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com