Rotating-drum yarn storing device for intermittent yarn storage and its manufacture

A manufacturing method and drum-type technology, which is applied to textiles, papermaking, textiles, looms, etc., can solve the problems of easy overlapping of yarns, yarn entanglement in weaving sections, poor yarn arrangement, etc., and achieve the effect of improving weaving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

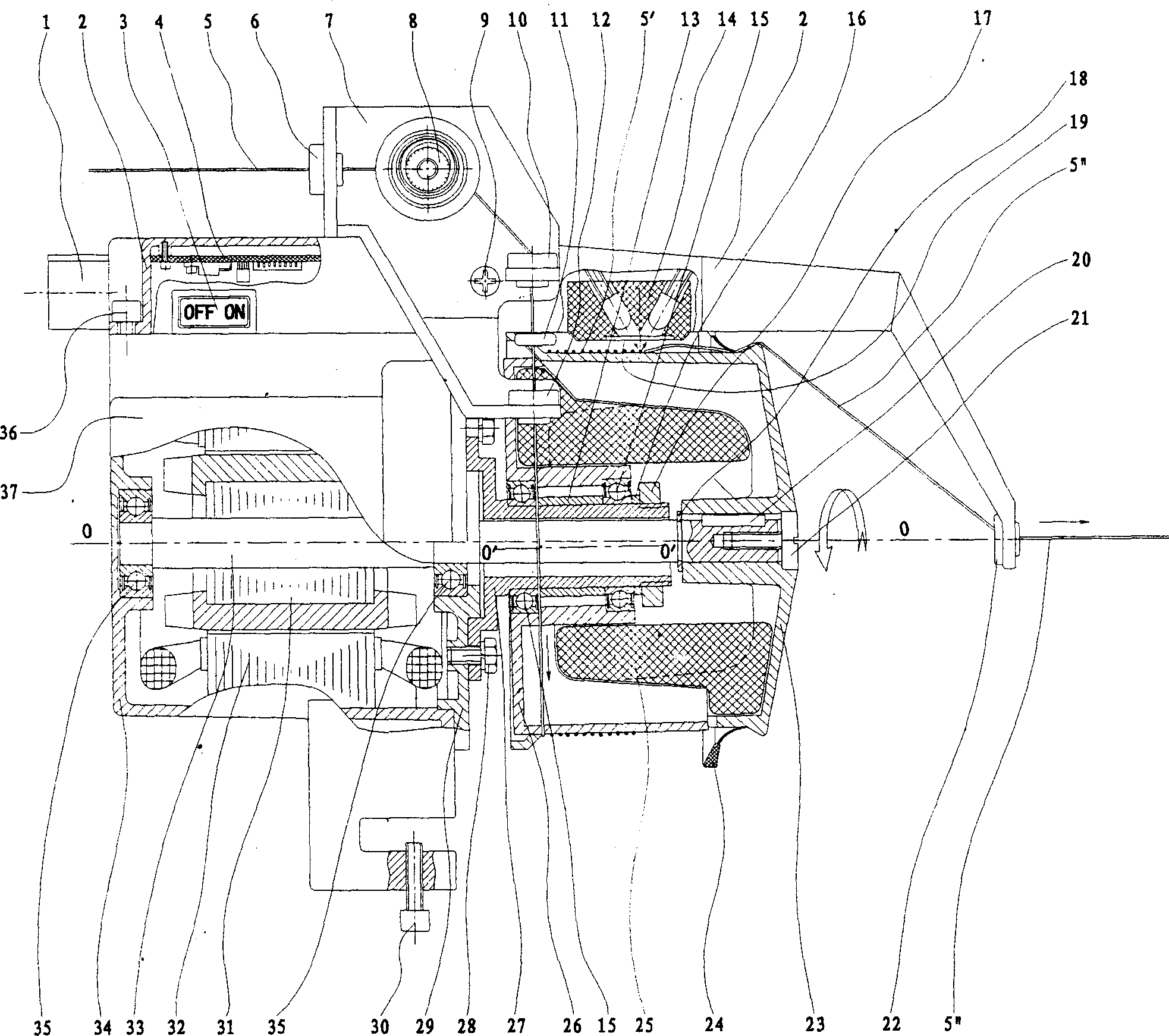

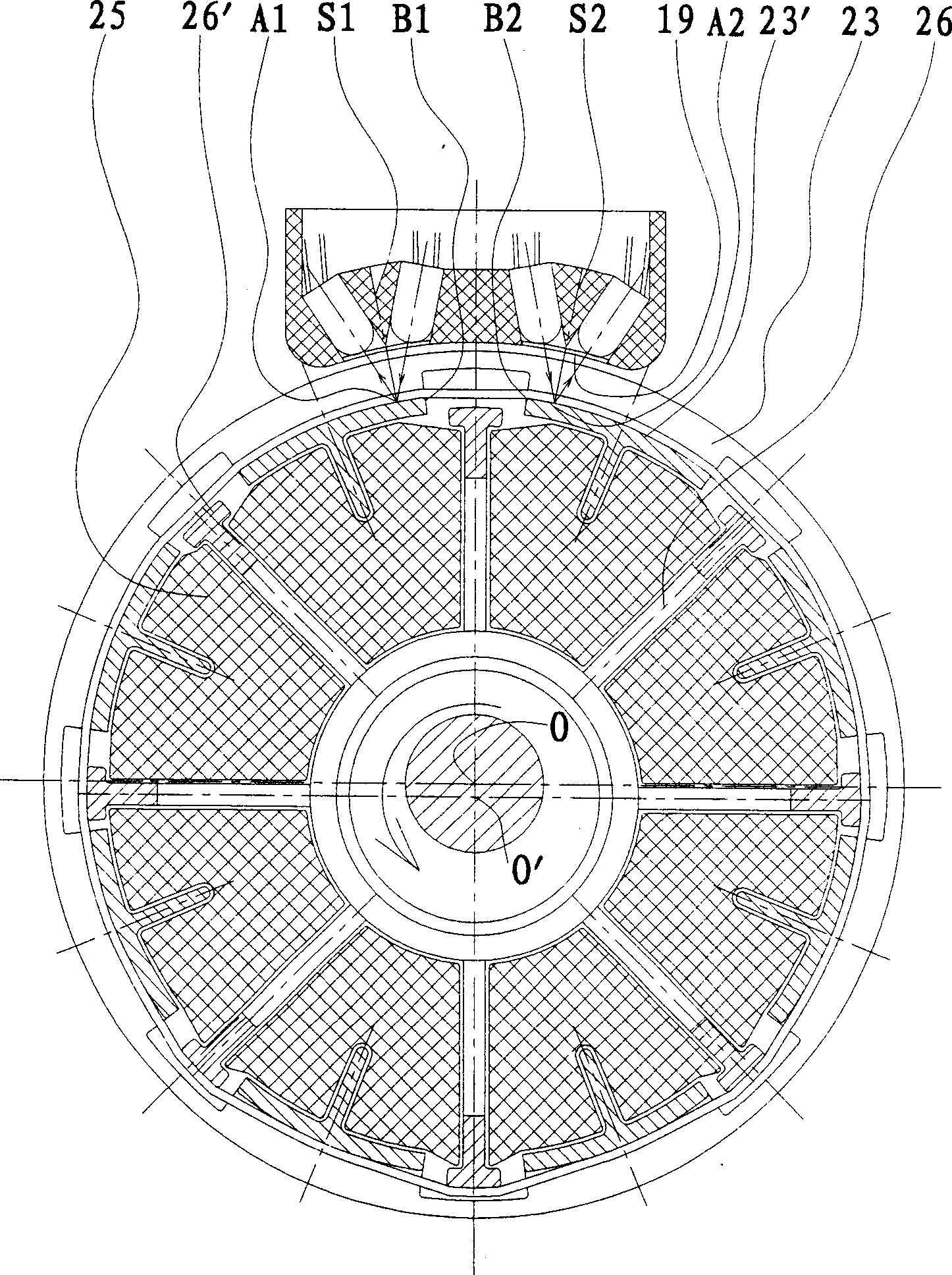

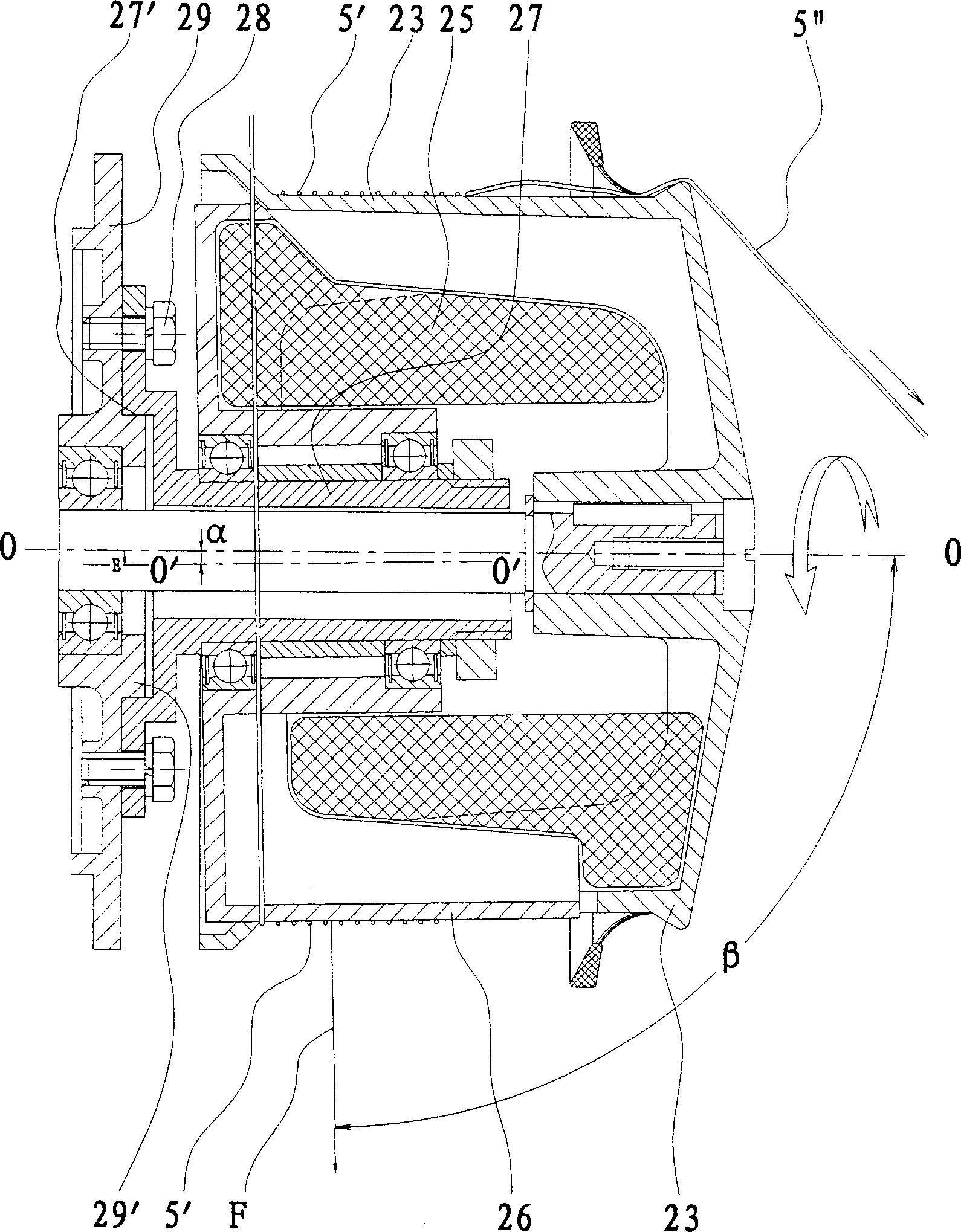

[0027] An embodiment of the yarn storage device of the present invention is as figure 1 shown. The upper cover plate (2) is installed on the top of the motor base (34), and the motor control circuit board (4), sensor (14), weft breaking switch (11), etc. are installed inside, and the power socket (1) is installed on the outside , switch (3) and yarn entering tensioner (7); the hollow inclined shaft (27) is installed on the motor end cover (29); the inner yarn drum (26) is installed on the hollow inclined shaft (27) through the bearing (15) , the inner yarn drum (26) can rotate around the hollow inclined shaft (27); the outer yarn drum (23) is fixedly connected with the motor shaft (33) by the key (20) and the screw (21); the inner yarn drum (26) is connected with the An elastic damping cover (25) made of sponge is housed between the outer yarn drums (23).

[0028] The yarn (5) from the bobbin passes through the porcelain eye (6) and enters the yarn tensioner (7), and is woun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com