High-strength vortex spinning yarn and production method thereof

A vortex spinning, high-strength technology, used in spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve the problem of antibacterial, low UV resistance, yarn strength, low wear resistance, Affect the comprehensive performance of the yarn and other issues, and achieve the effect of good cotton imitation effect, good wear resistance and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

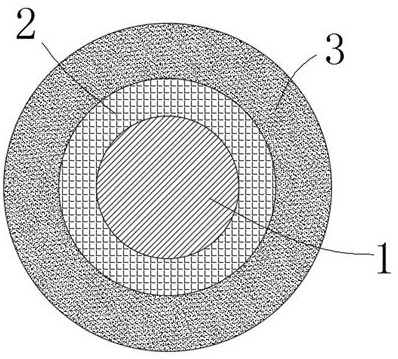

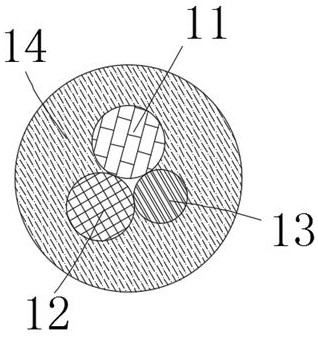

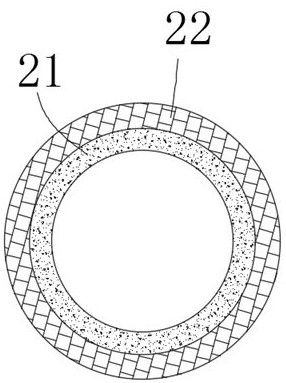

[0026] A high-strength vortex spun yarn, comprising a core yarn layer 1, a wrapping layer 2 and a wrapping layer 3, the wrapping layer 2 is arranged on the outer surface of the core yarn layer 1, and the wrapping layer 3 is arranged on the outside of the wrapping layer 2 On the surface, the core yarn layer 1 includes a first wire bundle 11, a second wire bundle 12, a third wire bundle 13 and a core fiber layer 14, and the first wire bundle 11, the second wire bundle 12 and the third wire bundle 13 are intertwined and arranged, and the core fiber layer 14 is arranged on the outside of the first wire harness 11, the second wire harness 12 and the third wire harness 13, the first wire harness 11 is a carbon fiber filament, the second wire bundle 12 is a nylon fiber filament, the third wire bundle 13 is a polyester fiber filament, the The diameter of the first wire bundle 11 is greater than the diameter of the second wire bundle 12, the diameter of the second wire bundle 12 is larg...

Embodiment 2

[0030] A production method of high-strength vortex spinning yarn, comprising the following steps:

[0031] S1, cutting carbon fiber filaments, nylon fiber filaments, polyester fiber filaments and polyester staple fibers;

[0032] S2. The cut carbon fiber filaments, nylon fiber filaments, polyester fiber filaments and polyester staple fibers are sequentially passed through the cotton grabbing machine, cotton mixing machine, cotton opener, double cotton box feeder, lapping machine, carding machine, etc. Cotton machine, drawing frame and vortex spinning machine to get the core yarn;

[0033] S3, the core yarn, hollow polyester fiber and bamboo viscose short fiber are passed through the vortex spinning machine, and the processing of eddy current twisting and composite yarn is carried out, the hollow polyester fiber is wound on the surface of the core yarn, and the bamboo viscose short fiber is wound on the surface of the core yarn Hollow polyester fiber surface, get prefabricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com