Garment ironing-free cool feeling finishing process

A non-iron cooling and non-iron finishing technology, which is applied in fiber treatment, improved hand-feel fibers, textiles and papermaking, etc. It can solve the problem of slow drying of cotton clothing, easy sticking of clothes to the skin, and increased stuffiness and discomfort And other problems, to achieve the effect of delicate hand feeling, increase supple comfort, and improve aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

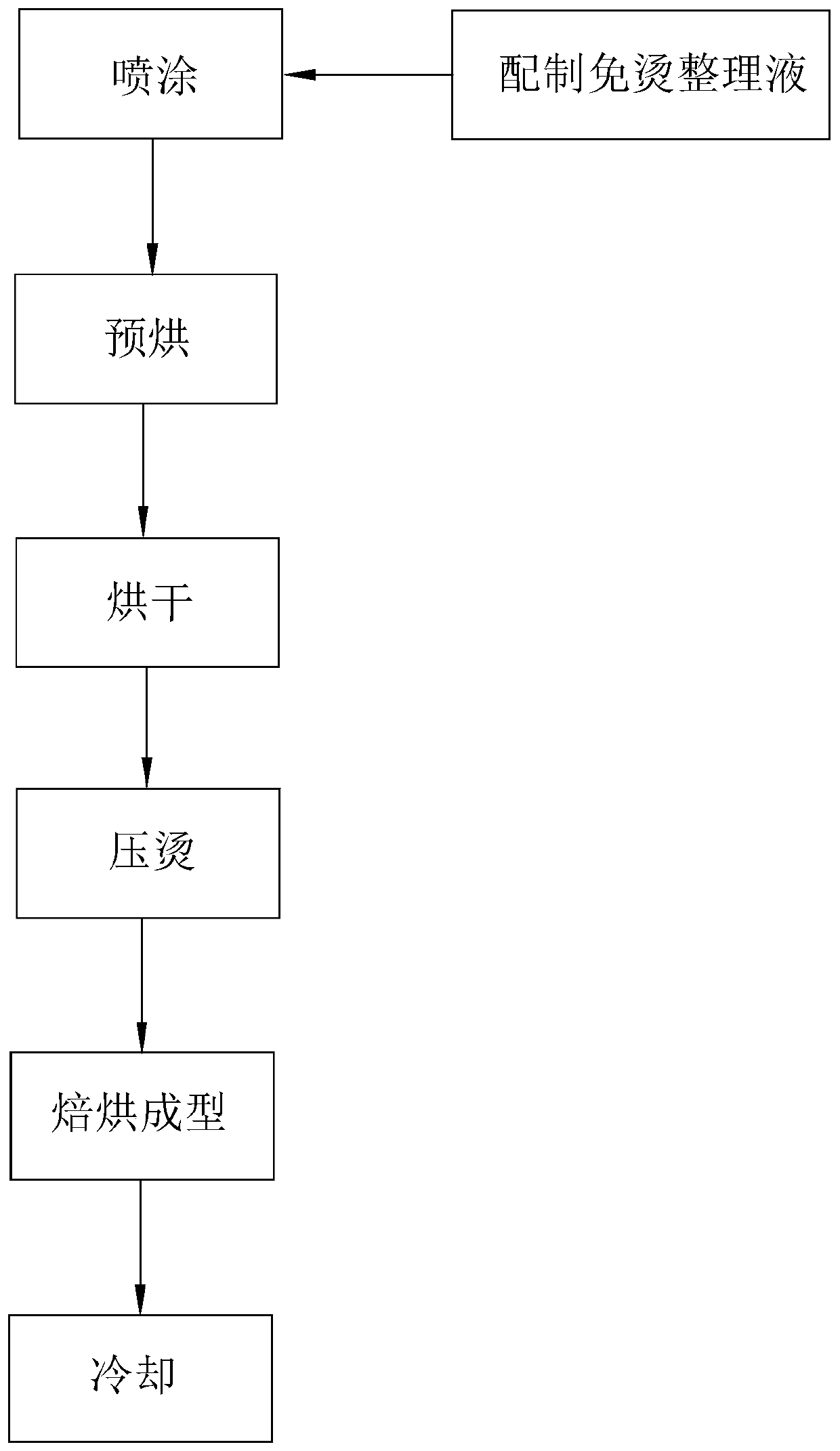

Method used

Image

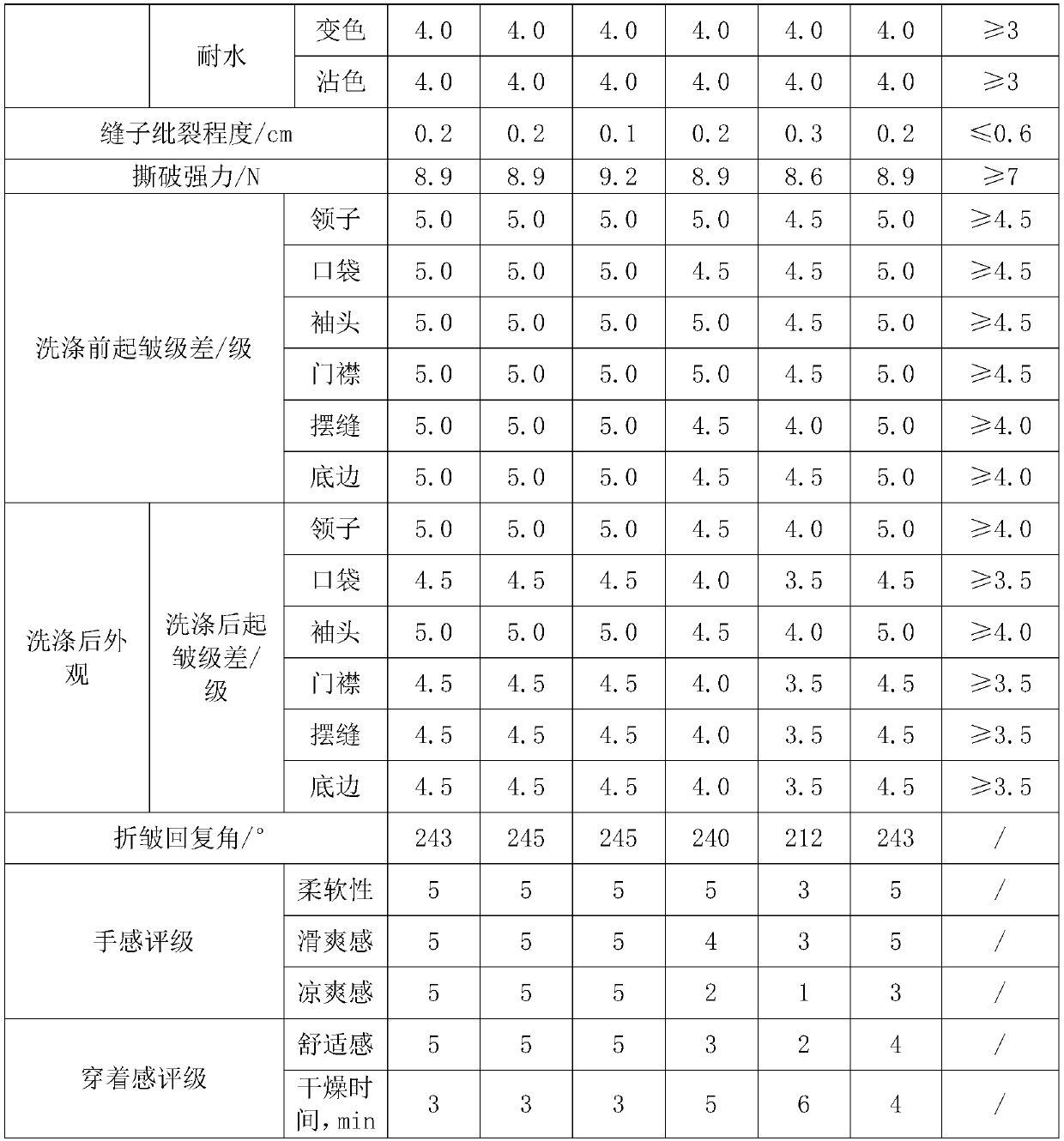

Examples

preparation example 1

[0039] Preparation example 1 of clothing cooling agent: ① take 30kg of water, add 3kg of glyceryl monocaprylate, 2kg of xylitol, 1kg of jade powder, and 1kg of alkyl glycoside to it, and stir to obtain a mixed solution;

[0040] ②Take 30kg of amino polyether polysiloxane block copolymer and 15kg of emulsifier, heat up to 60°C after mixing, stir at a speed of 2000r / min for 30min, then cool down to 30°C, add 0.5kg of glacial acetic acid and 10kg of water, After stirring at a speed of 400r / min for 10min; add 0.5kg of glacial acetic acid and 20kg of water, then stir at a speed of 400r / min for 15min; then add the mixed solution, and stir at a speed of 400r / min for 10min to obtain a clothing cooling agent.

preparation example 2

[0041] Preparation example 2 of clothing cooling agent: ① Take 30kg of water, add 4kg of glyceryl monocaprylate, 3kg of xylitol, 1.5kg of jade powder, and 1.5kg of alkyl glycoside to it, and stir to obtain a mixed solution;

[0042] ②Take 35kg of amino polyether polysiloxane block copolymer and 17.5kg of emulsifier, mix and heat up to 65°C, stir at a speed of 2500r / min for 35min, then cool down to 35°C, add 0.6kg of glacial acetic acid and 10kg of water , after stirring at a speed of 700r / min for 15min; adding 0.6kg of glacial acetic acid and 25kg of water, then stirring at a speed of 700r / min for 20min; .

preparation example 3

[0043] Preparation example 3 of clothing cooling agent: ① Take 30kg of water, add 5kg of glyceryl monocaprylate, 4kg of xylitol, 2kg of jade powder, and 2kg of alkyl glucoside to it, and stir to obtain a mixed solution;

[0044] ②Take 40kg of amino polyether polysiloxane block copolymer and 20kg of emulsifier, mix and heat up to 70°C, stir at a speed of 3000r / min for 40min, then cool down to 40°C, add 0.7kg of glacial acetic acid and 10kg of water, After stirring at a speed of 1000r / min for 20min; add 0.7kg of glacial acetic acid and 30kg of water, then stir at a speed of 1000r / min for 25min; then add the mixed solution, and stir at a speed of 1000r / min for 30min to obtain a clothing cooling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com