Multifunctional air vortex spinning yarn

A vortex spinning, multi-functional technology, applied in the direction of yarn, textile and papermaking, can solve the problems of single function and simple yarn structure, and achieve the effect of good structural strength, comfortable wearing and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

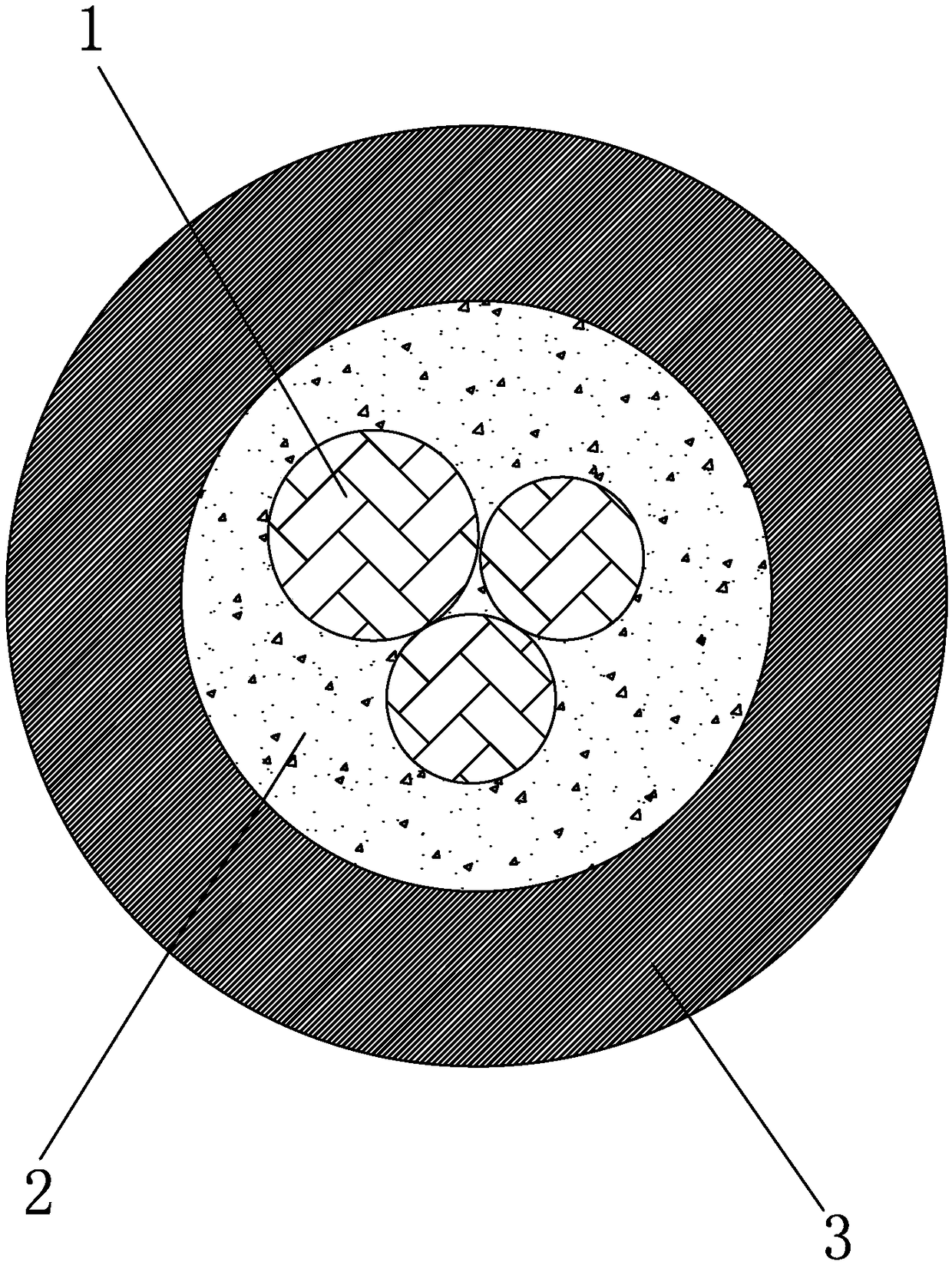

[0017] combine figure 1 , the invention discloses a multi-functional vortex spinning yarn, as a new type of functional yarn, which has a prominent surface in terms of flame retardancy, wear resistance and strength. The present invention includes a core yarn 1, an intermediate yarn 2 and a covering yarn 3. The core yarn 1 is formed by twisting and plying the first wire bundle, the first wire bundle and the third wire bundle. The first wire bundle is carbon fiber filament; the second wire bundle is nylon fiber filament; the third wire bundle is polyester fiber filament. The intermediate yarn 2 is aramid fiber staple. The core yarn 1 is located in the intermediate yarn 2; the core yarn 1 is first twisted and plyed, and the core yarn 1 and the intermediate yarn 2 are fed together from the vortex spinning core hole. Covered yarn 3 is a flame-retardant fiber layer. The covering yarn 3 is spirally wound and covered on the outside of the intermediate yarn 2 . The wrapped yarn 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com