Powdered fat composition for chocolate

A technology of oil composition and powder oil, which is applied in the direction of edible oil/fat, fat oil/fat/wax solidification, application, etc., to achieve the effects of high palatability, less adverse effects of flavor, and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] (A) Preparation process of oil composition I

[0065] The oil and fat composition prepared in the step (a) contains the above-mentioned XXX-type triglycerides (one or more) and X2Y-type triglycerides (one or more) in the mass %. Specifically, for example, XXX-type triglycerides (one or more) having a fatty acid residue X having a carbon number x at the 1st to 3rd positions, and a triglyceride having a carbon number y at the 1st to 3rd positions are obtained, respectively. YYY-type triglycerides (one or more) of fatty acid residues Y are mixed with the mass ratio of XXX-type triglycerides / YYY-type triglycerides in the range of 90 / 10 to 99 / 1 to obtain a reaction substrate ( Here, the aforementioned carbon number x is an integer selected from 8 to 20, the aforementioned carbon number y is an integer selected from x+2 to x+12, and y≤22), and the aforementioned reaction substrate is heated in the catalyst. There are processes that are obtained by performing ester exchange r...

Embodiment 1

[0118]

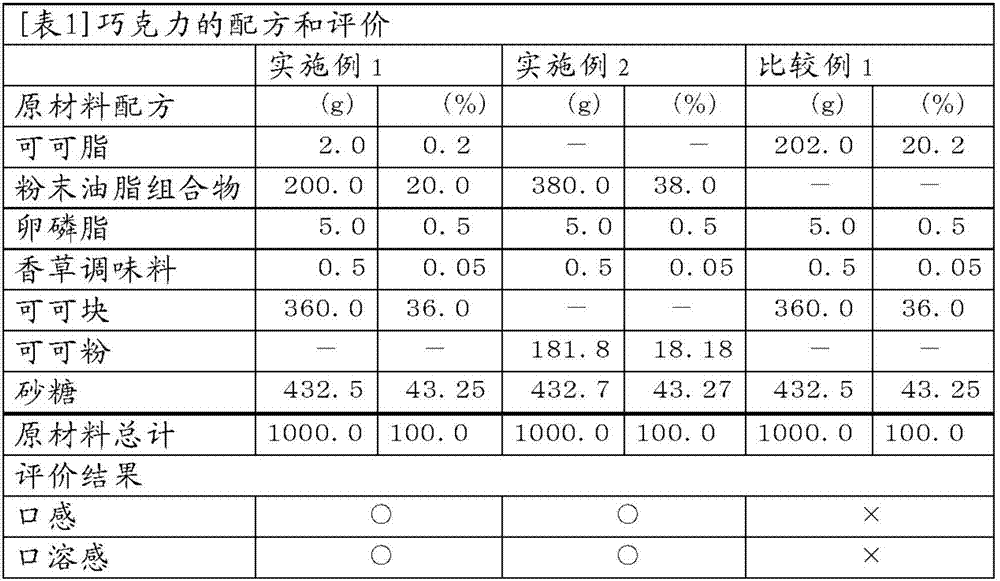

[0119] According to the recipe in Table 1 below, the chocolates of Examples 1-2 and Comparative Example 1 were produced by mixing, micronizing (refining) and conching according to conventional methods, followed by cooling and solidification. More specifically, raw materials (cocoa mass, cocoa butter, etc.) were mixed for about 5 minutes while heating to 60° C. with a stirrer (Universal Mixer 8XDML: manufactured by Dalton Co., Ltd.) to obtain a chocolate mass. The obtained chocolate material was pulverized with a roll refiner (SDY-type hydraulic three-roll mill: manufactured by BUHLER Co., Ltd.), and micronized to an average particle size of about 20 μm. Knead the refined chocolate base for more than 20 minutes with the aforesaid stirrer, and after liquefaction, adjust the oil content to make a chocolate stock solution. Adjust the temperature of the chocolate stock solution to 30°C, flow into the mold and shape it, then cool and solidify the chocolate stock solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com