Bubble type flexible non-woven cloth and manufacturing method thereof

A manufacturing method and technology of non-woven fabrics, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of high cost, limited soft effect, low output, etc., and achieve the effect of simple equipment transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: 14g / m 2 Polylactic acid spunbonded hot-rolled nonwoven fabric

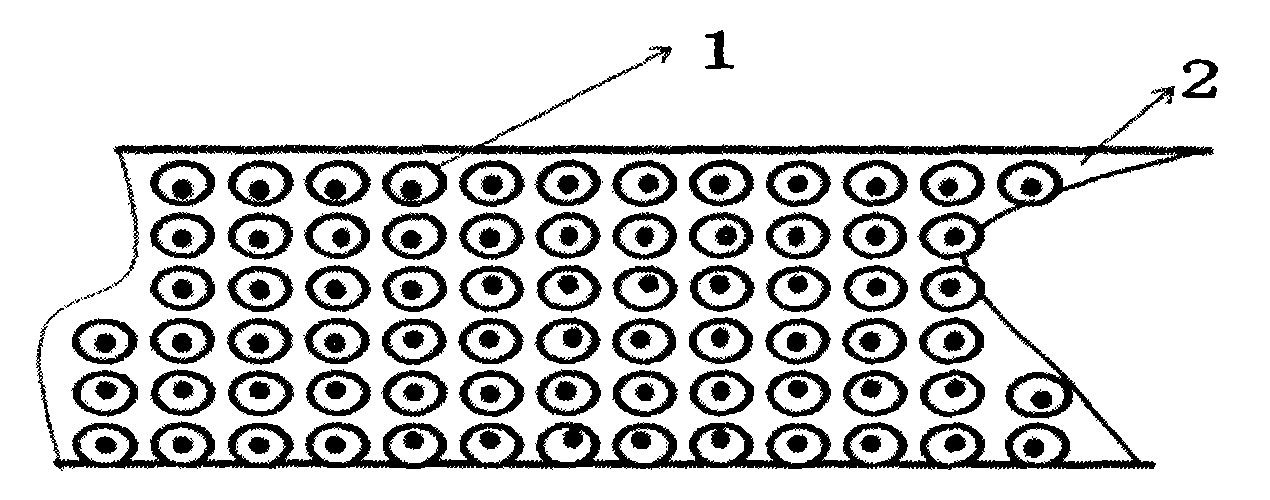

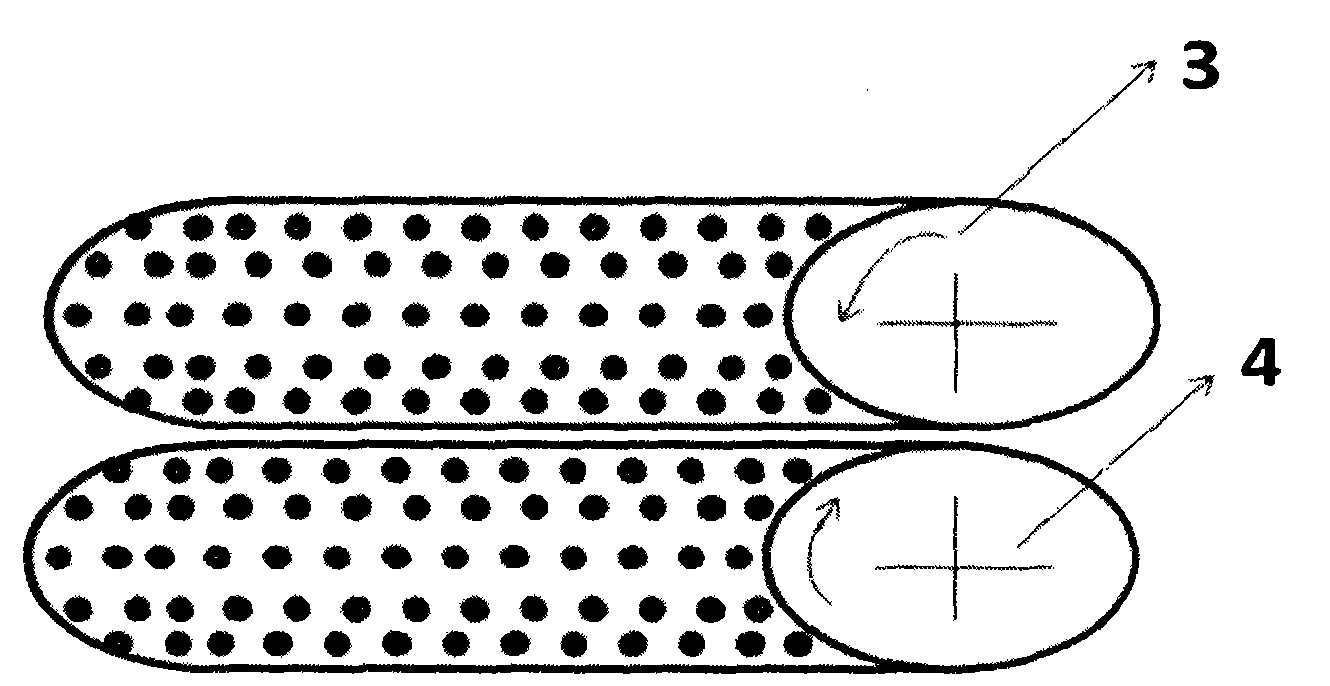

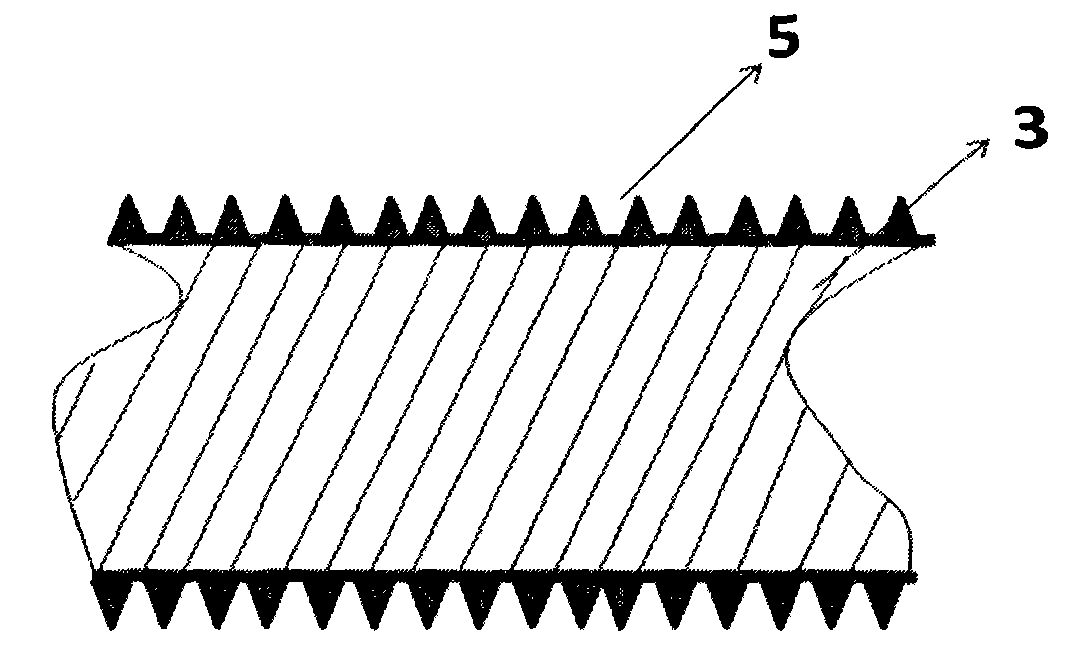

[0027] The technological process of polylactic acid spunbonded non-woven fabric is: slice drying → slice feeding → melt extrusion → spinning → cooling and drawing → splitting and laying web → hot rolling reinforcement of fiber web → trimming and winding. During the hot-rolled reinforcement process of the fiber web, such as figure 2 Shown, fiber web passes through upper roll (3) and lower roll (4) during hot rolling for the first time. Such as image 3 As shown, the rolling point of the upper hot roll (3) is a conical bump (5), and the cross-sectional area of the conical bottom is 15mm 2 , 3mm high, the concave point of the lower roller is cylindrical, with a cross-sectional area of 15mm 2 , the depth of the cylinder is 5mm, the top of the convex point (5) of the upper roller does not touch the bottom of the concave point of the lower roller, only the edges of the convex point and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com