Sugar-free oral cleaning candy with rebitter taste and preparation method thereof

A kind of clear and bitter technology, applied in the direction of confectionery, confectionery industry, food science, etc., can solve the problem of producing sweet and greasy feeling, affecting people's desire to eat, etc., to achieve the effect of convenient eating and unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Formula 70 parts of sorbitol, 10 parts of isomalt, 0.1 part of sucralose, 4 parts of citric acid, 0.1 part of rose essence, 0.1 part of menthol, and 0.5 part of magnesium stearate.

[0030] method

[0031] (1) After melting the sorbitol at 110°C, add isomalt with a particle size of 80-100 mesh, and after thorough stirring, keep it at 80-85°C for 60 minutes, and then keep it at a relative humidity of less than 40%, Cool overnight at a temperature lower than 20°C, pulverize, and pass through a 60-mesh sieve to obtain sorbitol granules;

[0032] (2) cross 80 mesh sieves after other remaining ingredients except magnesium stearate are mixed in the formula, add preceding step gained sorbitol granules and magnesium stearate, mix homogeneously;

[0033] (3) tableting, sorting and packaging.

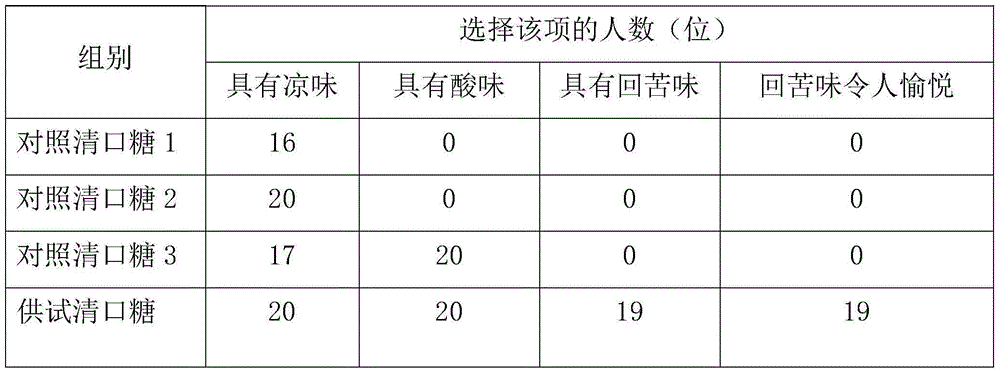

[0034] Taste evaluation

[0035] Test method: A single-blind method was adopted, and a total of 20 people (half male and half female) participated in the evaluation. Each person was gi...

Embodiment 2

[0040] Formula 80 parts of sorbitol, 20 parts of isomalt, 0.6 parts of sucralose, 4 parts of citric acid, 2 parts of passion fruit flavor, 0.1 part of menthol, and 1.0 part of magnesium stearate.

[0041] method

[0042] (1) After melting the sorbitol at 110°C, add isomalt with a particle size of 80-100 mesh, and after thorough stirring, keep it at 80-85°C for 60 minutes, and then keep it at a relative humidity of less than 40%, Cool overnight at a temperature lower than 20°C, pulverize, and pass through a 60-mesh sieve to obtain sorbitol granules;

[0043] (2) cross 80 mesh sieves after other remaining ingredients except magnesium stearate are mixed in the formula, add preceding step gained sorbitol granules and magnesium stearate, mix homogeneously;

[0044] (3) tableting, sorting and packaging.

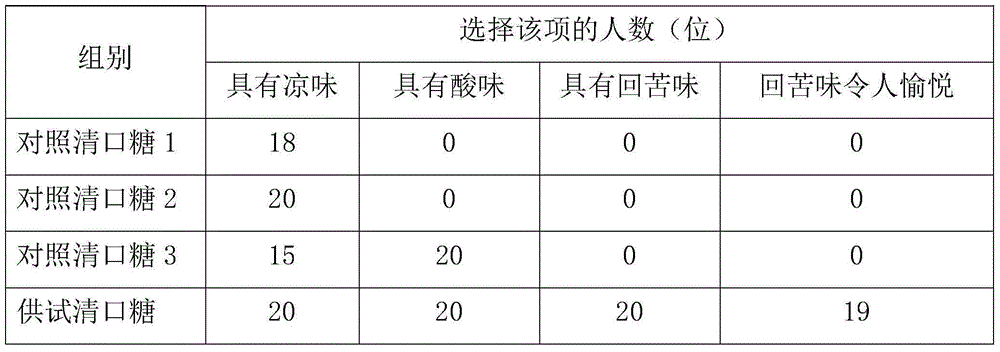

[0045] Taste evaluation

[0046] Test method: A single-blind method was adopted, and a total of 20 people (half male and half female) participated in the evaluation. Each perso...

Embodiment 3

[0051] Formula 75 parts of sorbitol, 15 parts of isomalt, 0.3 part of sucralose, 4 parts of citric acid, 0.6 part of lemon flavor, 0.1 part of menthol, 0.2 part of magnesium stearate.

[0052] method

[0053] (1) After melting the sorbitol at 110°C, add isomalt with a particle size of 80-100 mesh, and after thorough stirring, keep it at 80-85°C for 60 minutes, and then keep it at a relative humidity of less than 40%, Cool overnight at a temperature lower than 20°C, pulverize, and pass through a 60-mesh sieve to obtain sorbitol granules;

[0054](2) cross 80 mesh sieves after other remaining ingredients except magnesium stearate are mixed in the formula, add preceding step gained sorbitol granules and magnesium stearate, mix homogeneously;

[0055] (3) tableting, sorting and packaging.

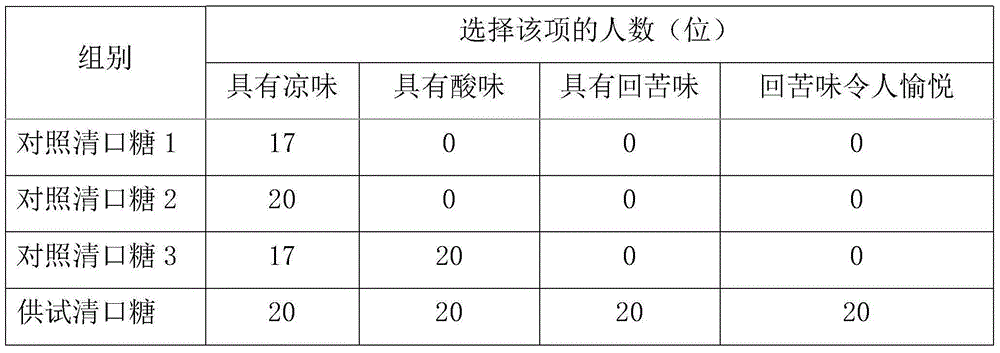

[0056] Taste evaluation

[0057] Test method: A single-blind method was adopted, and a total of 20 people (half male and half female) participated in the evaluation. Each person was given f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com