Oil composition, preparation method thereof and foodstuffs

A technology of oil composition and manufacturing method, which is applied in the direction of cream preparations, dairy products, edible oil/fat, etc., can solve the problems of low content of saturated fatty acids, low content of trans fatty acids, and sticky taste of oils, etc., and achieve rapid Crystallization rate, fast melting, effect of increasing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The preparation method of oil composition of the present invention comprises:

[0087] Esterification of monoglyceride or a composition comprising monoglyceride with lauric acid or a composition comprising lauric acid.

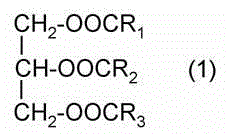

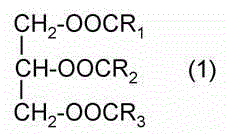

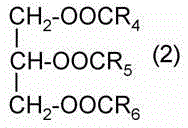

[0088] The monoglyceride refers to the monoester of glycerol and straight-chain or branched-chain fatty acid with more than 16 carbon atoms (preferably straight-chain saturated fatty acid with 16 carbon atoms). In the composition comprising monoglyceride, based on the weight of the composition comprising monoglyceride, the content of monoglyceride is not less than 30%, preferably not less than 40%, preferably not less than 50%, preferably not less than 60%, preferably not less than 70%, preferably not less than 80%, more preferably not less than 90% (such as monoglyceride with 60% monoester content, 35% diester content, and 5% triester content).

[0089]According to the production method, wherein based on the weight of the composition containing lauric...

Embodiment 1

[0121] Mix 10 mole parts of molecularly distilled monoglyceride (Kerry Oleochemical Industry (Shanghai) Co., Ltd.) with 20 mole parts of lauric acid (Yihai (Lianyungang) Oil Chemical Industry Co., Ltd.), put it into a three-necked flask, and heat to 200°C , the esterification reaction was 2 hours, and the temperature was naturally lowered for 2 hours; the oil obtained from the reaction was molecularly distilled at 200°C to remove unreacted lauric acid, monoglyceride and diglyceride, and the obtained oil (sample 1) was referred to TAG: The method detection of AOCSofficalmethod Ce5-86, wherein the detection results of LLH and SSS content are shown in Table 1.

Embodiment 2

[0123] Mix 800g of fully hydrogenated palm kernel stearin (Kerry Specialty Oils Co., Ltd.) with 200g of fully hydrogenated palm stearin (Kerry Specialty Oils Co., Ltd.), put it into a three-necked flask, add 0.1% sodium methoxide, and react at 100°C for 40 minutes , naturally cool down for 2 hours to obtain transesterified grease A; mix the obtained transesterified grease A with acetone in a weight ratio of 1:4, cool to 22°C, and filter; continue to cool the filtrate to 10°C, filter, and rinse the filter cake with acetone , collected the solid fat, and tested the obtained solid fat (sample 2) with reference to the method of TAG: AOCSofficalmethod Ce5-86, and the detection results of LLH and SSS content are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com