Production method for high-strength anti-static nylon dyeing cloth with moisture absorbing and sweat releasing functions

A moisture-wicking, anti-static technology, applied in the processing of textile materials, yarn, heating/cooling fabrics, etc., can solve the problems of wrinkle resistance, poor shape retention, poor water conductivity, poor low temperature resistance, and slow water dispersion. Achieve the effects of excellent moisture absorption and perspiration performance, durable anti-static performance, and excellent wearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the present invention are clearly and completely described below in conjunction with the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

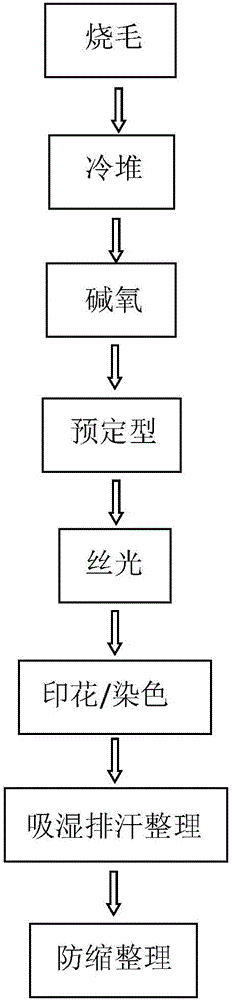

[0029] A method for preparing nylon high-strength antistatic moisture-absorbing sweat-wicking printing and dyeing cloth, comprising the following steps:

[0030] Step 1: Using 45-inch long-staple cotton yarn and 40D nylon yarn as raw materials, the blended yarn is spun by a single double-wrapping method and then woven into gray fabric. The weaving process is: long-staple cotton and nylon winding→cotton nylon and nylon conductive Two-for-one twisting of staple fiber → weaving, the specification of gray cloth is (45+40D) / 2×(45+40D) / 2 / 60×42;

[0031] Step 2: the gray cloth is singed by a gas singeing machine, and the fire is extinguishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com