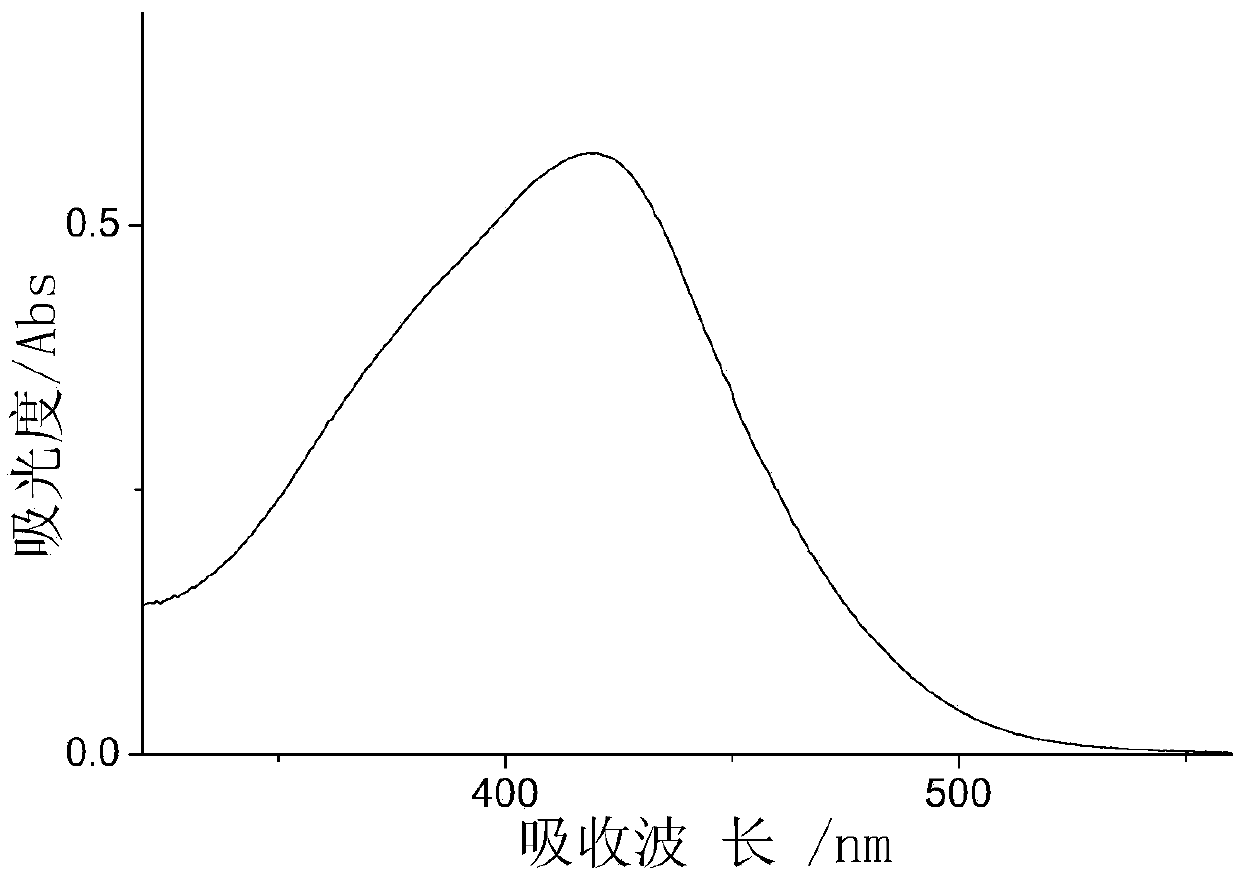

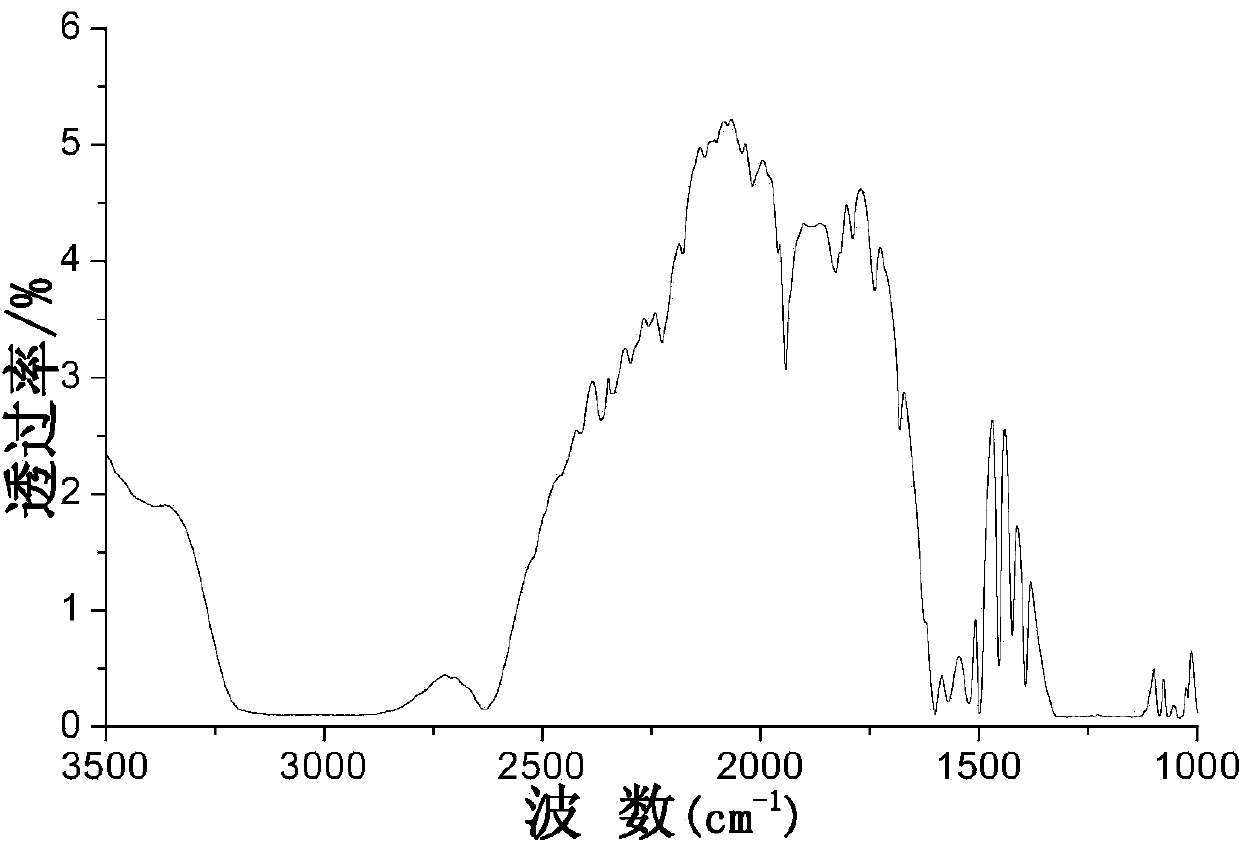

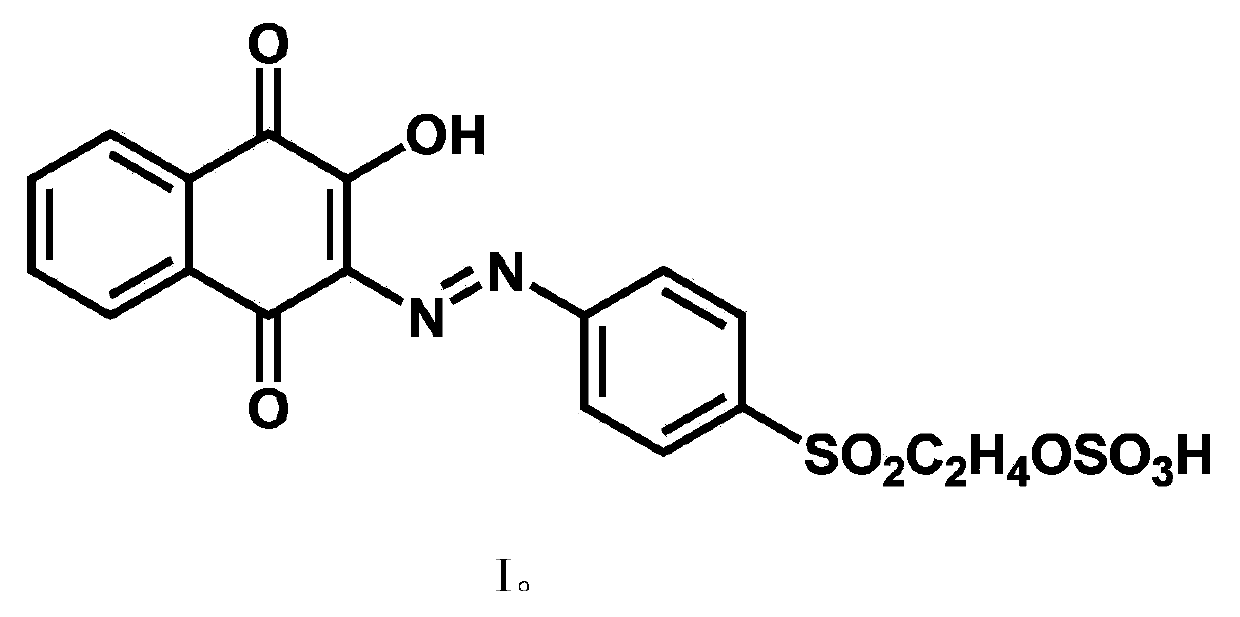

Naphthaquinone-type brown reactive disperse dye and preparation method thereof

A reactive disperse dye, naphthoquinone type technology, used in reactive dyes, dyeing methods, organic dyes, etc., to achieve excellent dyeing fastness, bright dyeing, and good dyeing synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of naphthoquinone type brown reactive disperse dye, described preparation method comprises the steps:

[0029] 1. P-beta-hydroxyethyl sulfone sulfate aniline, deionized water and crushed ice are beaten in an ice bath to obtain an ice solution of p-beta-hydroxyethyl sulfone sulfate aniline, and the p-beta-hydroxyethyl sulfone sulfuric acid The molar ratio of ester aniline, deionized water and crushed ice is 1:10:10; dissolving sodium nitrite in deionized water and adding crushed ice to obtain an ice solution of sodium nitrite, the sodium nitrite, deionized water The molar ratio with crushed ice is 1.2:10:10; mix the ice solution of p-β-hydroxyethyl sulfone aniline with the ice solution of sodium nitrite to obtain solution I; the p-β-hydroxyethyl The molar ratio of sulfone sulfate aniline to sodium nitrite is 1:1.2;

[0030] ② Add concentrated hydrochloric acid to solution I, stir at 5°C for 30 minutes, adjust the pH value to 6 to obtain solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com