Color polymer dispersed liquid crystal thin film and preparation method thereof

A technology for dispersing liquid crystals and polymers, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems such as single color and limited use, and achieve bright dyeing, high contrast, and beautiful visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

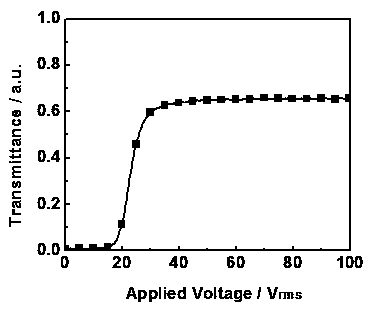

Embodiment 1

[0014] Nematic liquid crystal E7, polythiol compound (T-35) and bisphenol A epoxy resin (E-51) are selected, the mass ratio of the two thermally polymerizable monomers is 1:1, and the liquid crystal and polymerizable monomer The mass ratio is 4:6. Select an oil-soluble azo-type blue dye, which accounts for 1% of the total mass of the liquid crystal and polymerized monomers, mix the dye and the liquid crystal evenly at room temperature, and then add bisphenol A epoxy resin and stir. Then, spacer particles with a diameter of 20 microns are selected and added to the stirring system, and the spacer particles account for 0.5% of the total mass of the liquid crystal and the polymerized monomer. Then add polythiol compound, add curing agent after stirring for 5 minutes, curing agent accounts for 2% of the total mass of polymerized monomers. After stirring for 3 minutes, the mixture is sandwiched between two layers of polyester conductive films coated with indium tin oxide, and Extru...

Embodiment 2

[0017] Nematic liquid crystal slc1717, polythiol compound (T-35) and bisphenol A epoxy resin (E-51) are selected, the mass ratio of the two thermally polymerizable monomers is 1:1.2, and the liquid crystal and polymerizable monomer The mass ratio is 9:11. Choose an oil-soluble anthraquinone red dye, accounting for 1.5% of the total mass of the liquid crystal and polymerized monomers, mix the dye and the liquid crystal evenly at room temperature, and then add bisphenol A epoxy resin and stir. Then, spacer particles with a diameter of 15 microns are selected and added to the stirring system, and the spacer particles account for 0.5% of the total mass of liquid crystal and polymerized monomers. Then add polythiol compound, add curing agent after stirring for 4 minutes, curing agent accounts for 5% of the total mass of polymerized monomers, stir for 3 minutes and then sandwich the mixture between two layers of polyester conductive films coated with indium tin oxide, use Extrude w...

Embodiment 3

[0019] Nematic liquid crystal slc7011, polythiol compound (T-35) and bisphenol A epoxy resin (E-54) are selected, the mass ratio of the two thermally polymerizable monomers is 1:1, and the liquid crystal and polymerizable monomer The mass ratio is 1:1. Choose an oil-soluble azo-type yellow dye, which accounts for 2% of the total mass of the liquid crystal and polymerized monomers, mix the dye and the liquid crystal evenly at room temperature, and then add bisphenol A epoxy resin and stir. Then, spacer particles with a diameter of 25 microns are selected and added to the stirring system, and the spacer particles account for 0.6% of the total mass of liquid crystals and polymerized monomers. Then add a polythiol compound, stir for 5 minutes and then add a curing agent, the curing agent accounts for 7% of the total mass of the polymerized monomers. After stirring for 3 minutes, the mixture was sandwiched between two layers of polyester conductive films coated with indium tin oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com