Raw wool scouring agent

A wool scouring agent and scouring agent technology, applied in the directions of detergent compounding agent, detergent composition, dry-cleaning fiber products, etc. The effect of high net rate, low residual fat rate and good whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the raw wool scouring agent in this embodiment includes the following components and weight ratio: isomeric tridecyl alcohol polyoxyethylene ether (1370) 40%~80%; secondary alkyl sulfonate sodium (SAS- 60) 2% to 14%; diethylene glycol 3% to 8%; ethylene glycol 2%; water balance.

[0049]Configuration process: Add the components isomeric tridecyl alcohol polyoxyethylene ether, sodium secondary alkyl sulfonate and diethylene glycol in sequence into the reactor, then add hot water, stir and dissolve. temperature to room temperature, after the foam disappears, add component B2 and stir evenly, then add a pH regulator to adjust the pH of the solution to 6.0-7.5. Bottling, sampling and testing. When cleaning the raw wool, the temperature is controlled at 46-60°C. The addition ratio is 0.3% of the weight of the water body.

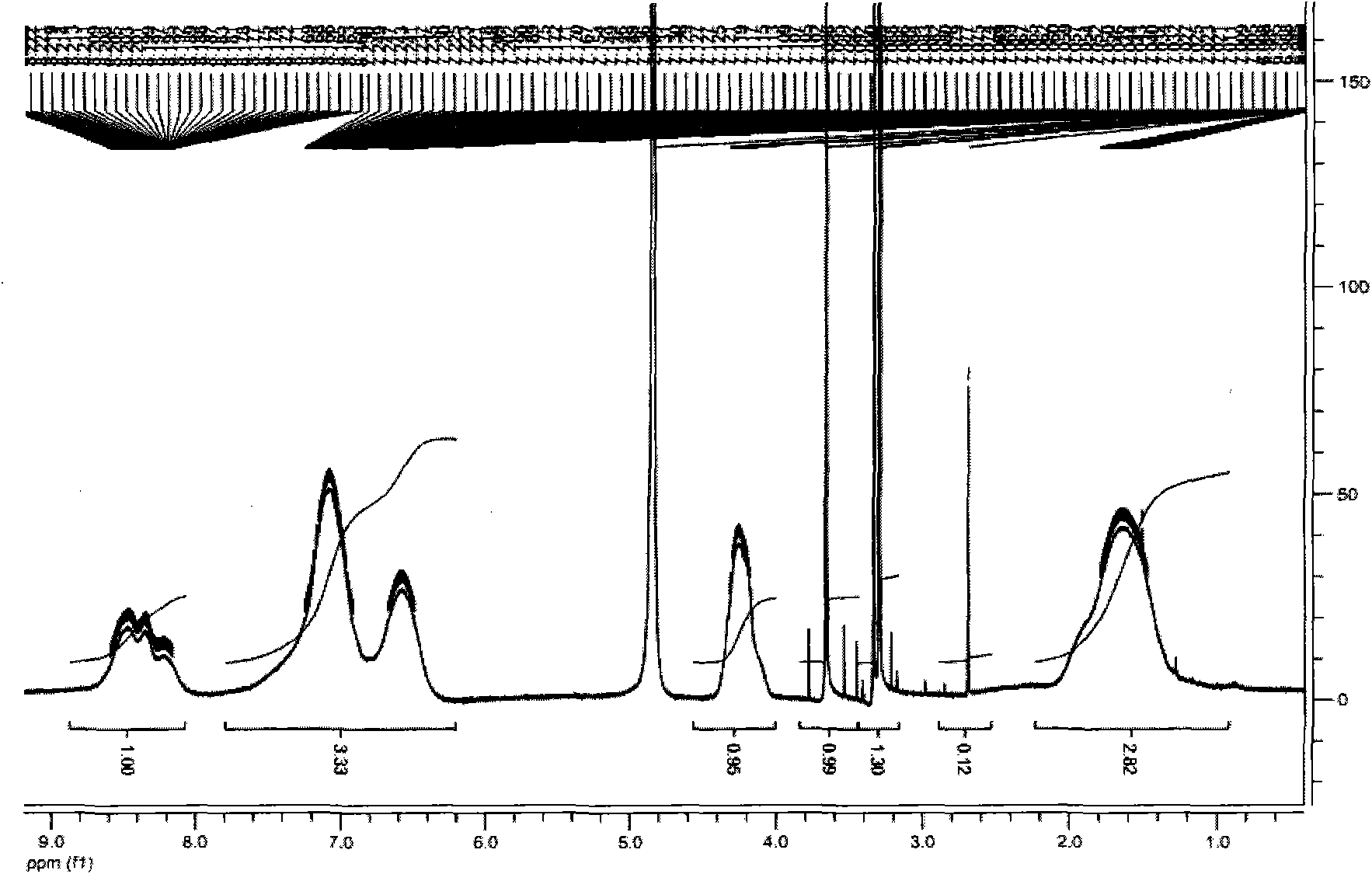

[0050] After blending comparison and performance testing to obtain the best formula composition. Optimization for isomeric tridecanol et...

Embodiment 2

[0076] Embodiment 2: the detergent in the present embodiment comprises following component and weight proportion:

[0077] Isomerized Tridecyl Polyoxyethylene Ether 70%;

[0078] Sodium secondary alkyl sulfonate 6%;

[0079] Diethylene glycol 6%;

[0080] Ethylene glycol 2%;

[0081] Polymer A 5%

[0082] water 11%,

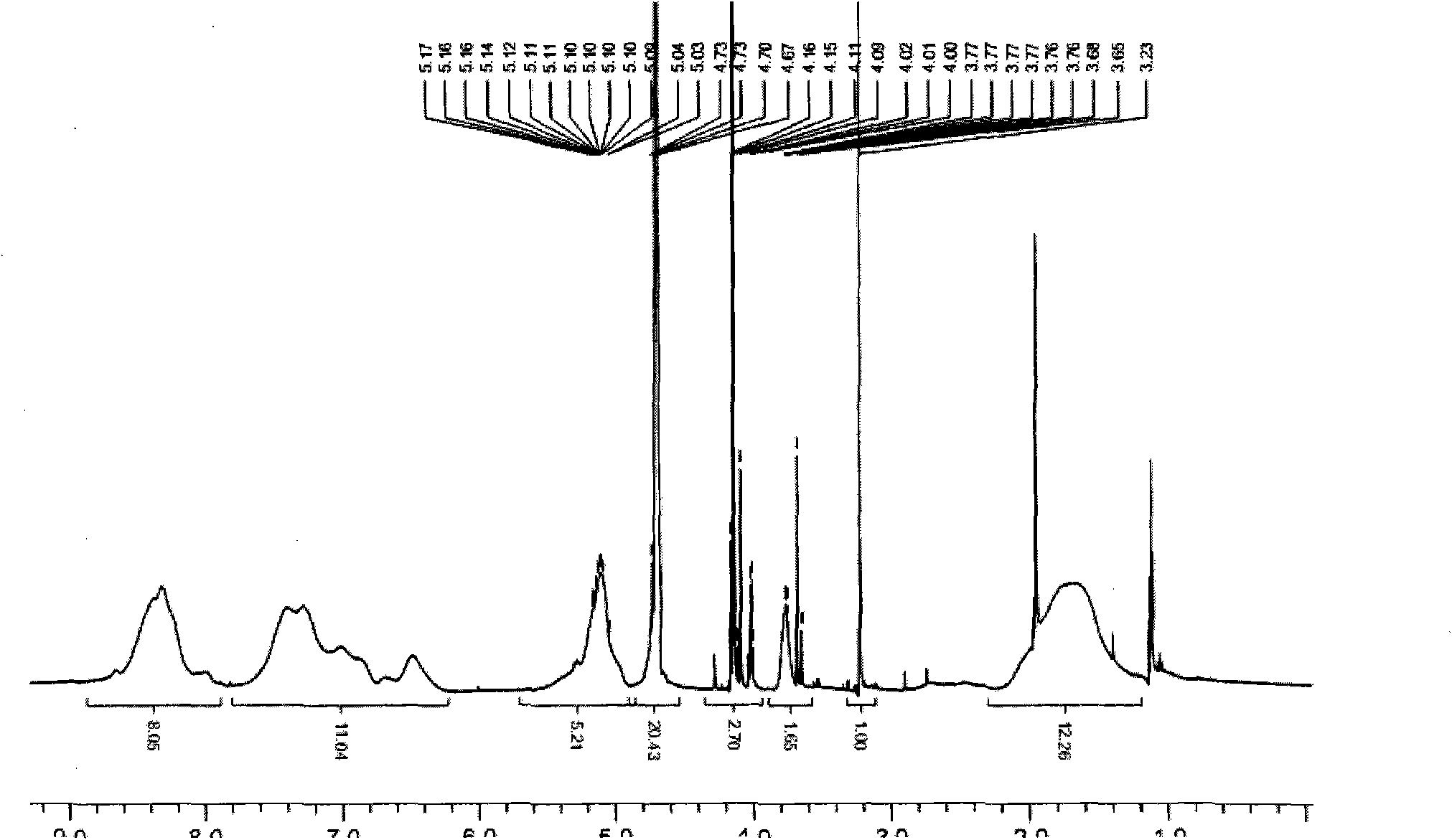

[0083] The molecular expression of polymer A is

[0084] Among them, a, b, and n are all natural numbers, which can be adjusted. The formula of detergent in this embodiment is named wooltech CIQ120.

[0085] The synthesis of polymer A has two technical schemes:

[0086] The first one is to synthesize the quaternary ammonium salt monomer by reacting 4-vinylpyridine and chloroacetic acid first, then the quaternary ammonium salt monomer and styrene are mixed and polymerized under the action of the initiator AIBN (azobisisobutyronitrile) to form A , the specific reaction equation is expressed as:

[0087]

[0088] The second one is first mixed with styr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com