Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "ALKYL ARYL SODIUM SULFONATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant oil base drilling fluid emulsifier

ActiveCN103725268AStrong anti-pollutionStrong forceDrilling compositionTemperature resistanceStearic acid

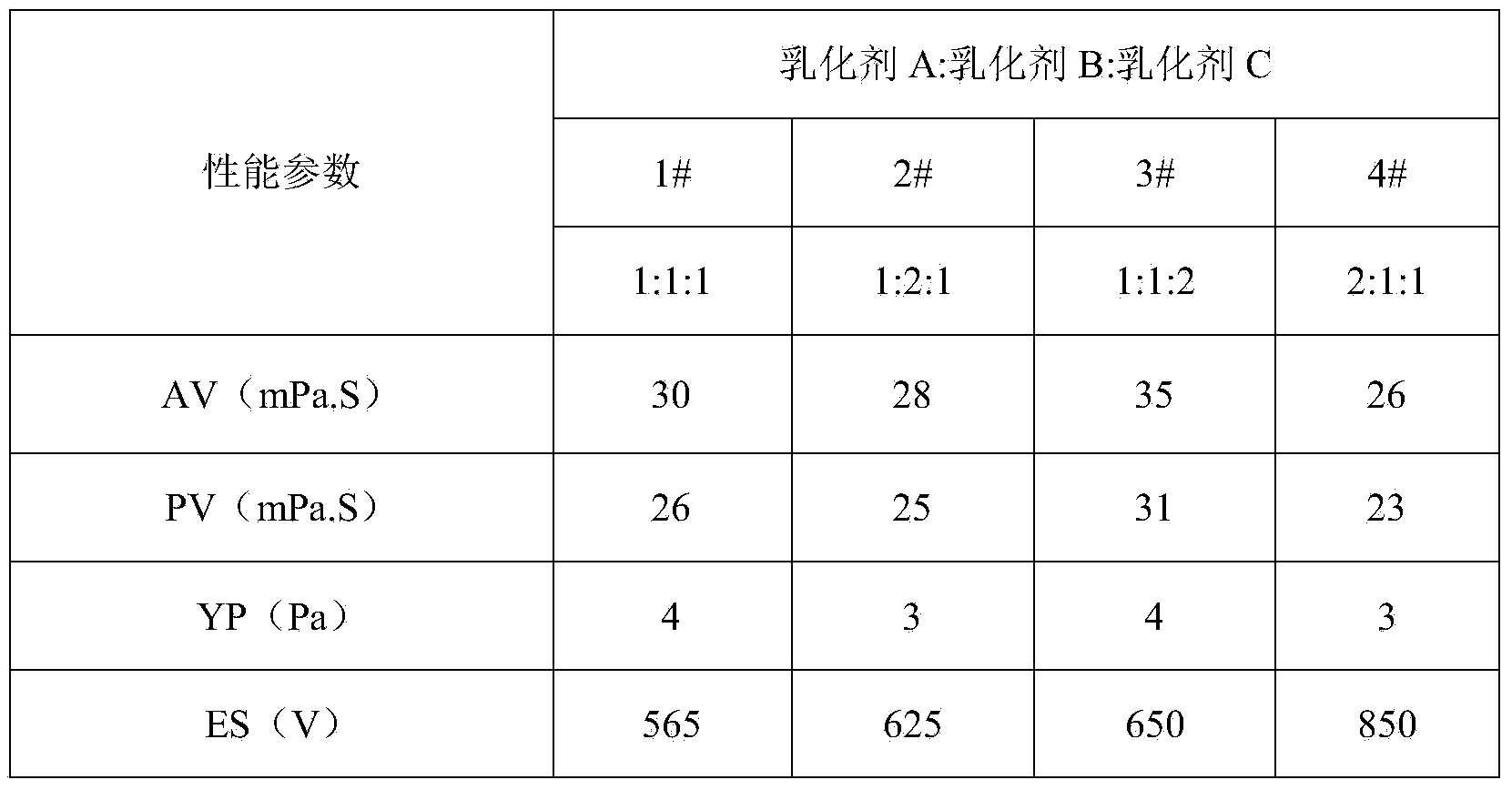

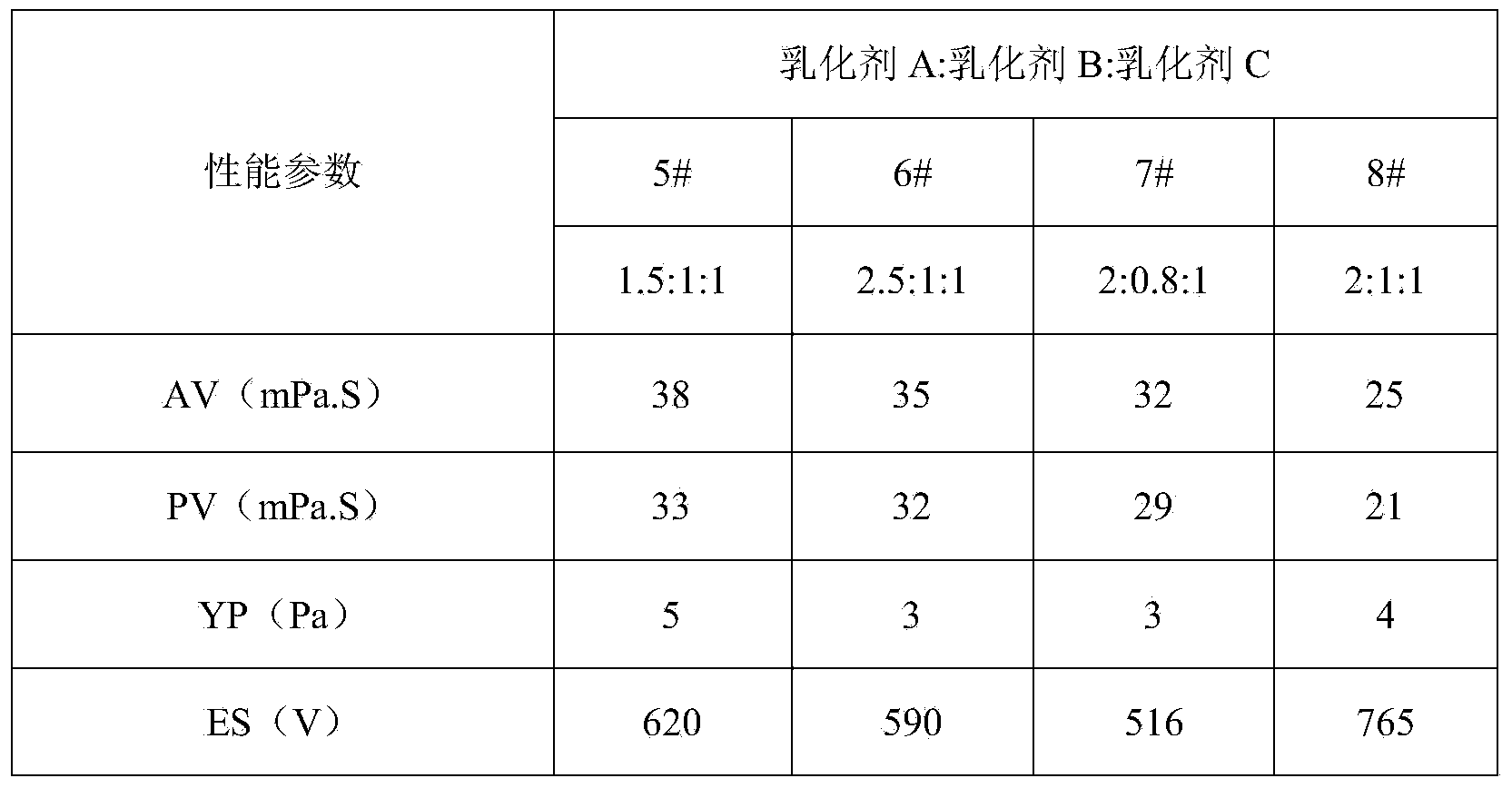

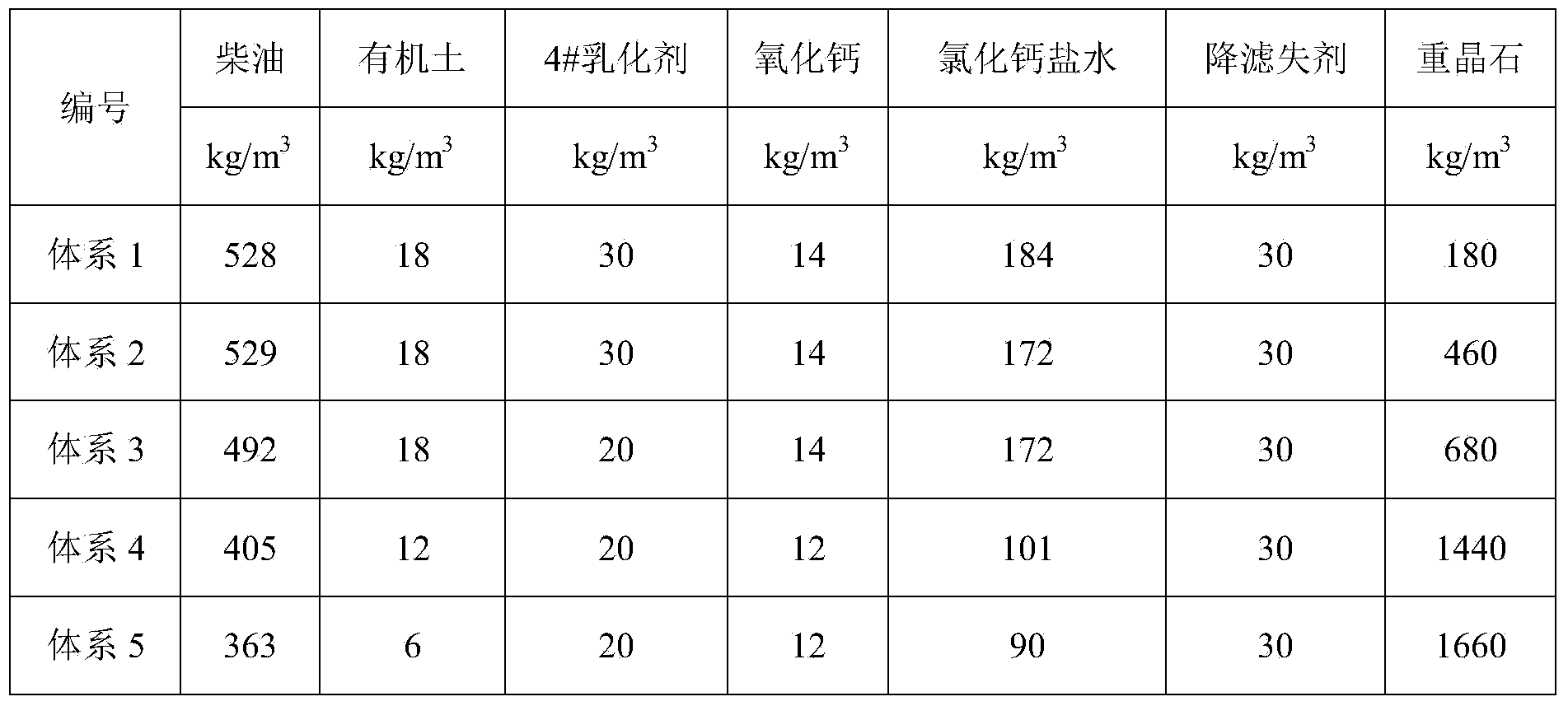

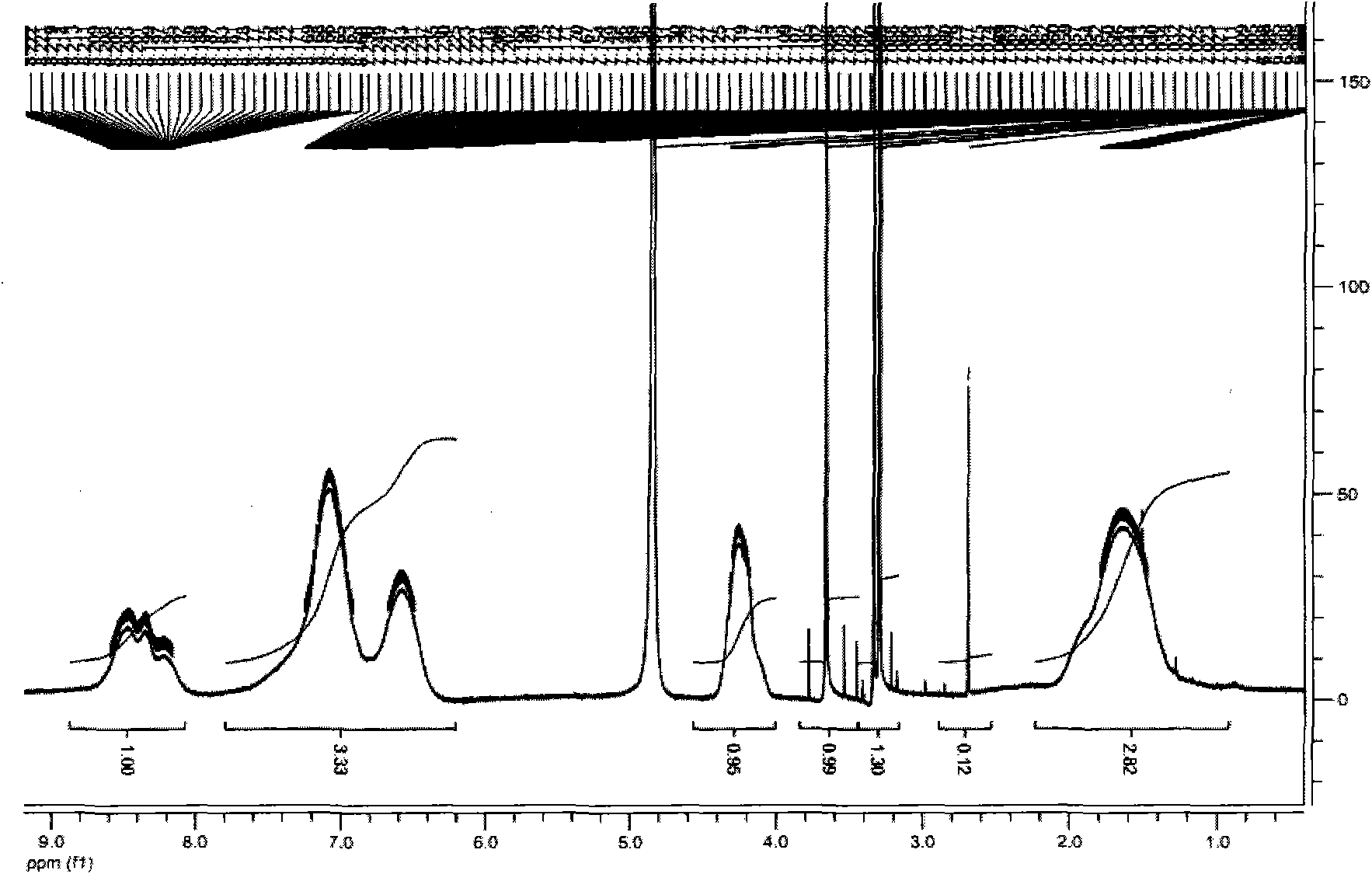

The invention discloses a high-temperature-resistant oil base drilling fluid emulsifier which consists of the following components: an emulsifier A, an emulsifier B and an emulsifier C, wherein the emulsifier A refers to a long-chain alkyl aliphatic alcohol amide type nonionic surfactant; the emulsifier B refers to sulfonate; the emulsifier C refers to stearate; a mass ratio of the emulsifier A to the emulsifier B to the emulsifier C is (1.5-2.5):(0.8-1.2):1; the emulsifier B is selected from one or more of petroleum iron sulfonate, sodium alkyl benzene sulfonate, sodium alkylarysulfonate and sodium alkyl succinate sulfonate; the emulsifier C is selected from one or two of polyoxyethylene stearate or zinc stearate. The high-temperature-resistant oil base drilling fluid emulsifier is used for forming water-in-oil emulsion for drilling fluid, and the emulsifier has the characteristics of high temperature resistance (180 DEG C), high pollution resistance and compatibility with other treatment agents and can be widely applied to the oil base drilling fluid.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

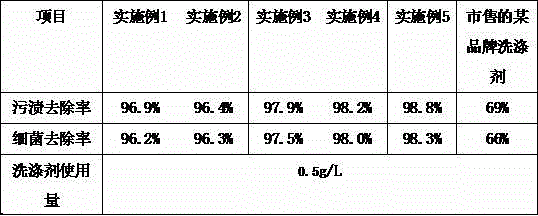

Raw wool scouring agent

InactiveCN102041187AImprove cleaning rateLow residual fat rateOrganic detergent compounding agentsNon-ionic surface-active compoundsDiethylene glycolScouring agent

The invention relates to a raw wool scouring agent which is characterized by comprising the following components by weight percent: 40%-80% of iso-tridecanol polyoxyethylene ether, 2%-14% of alkyl aryl sodium sulfonate, 3%-8% of diethylene glycol, 2% of glycol and the balance of water. The invention further discloses a wool scouring agent with an antistatic function and a bactericidal function. The wool scouring agent has the advantages of high cleaning rate, low fan and oil content, excellent whiteness, good hand feeling and good biodegradability.

Owner:傅科杰

Ceramic cleaning agent

InactiveCN105002020ALarge specific surface areaGood synergySurface-active non-soap compounds and soap mixture detergentsAlkylphosphateCleansing Agents

The invention belongs to the technical field of articles of daily use, and more specifically relates to a ceramic cleaning agent. The ceramic cleaning agent comprises following raw materials, by weight, 8 to 12 parts of acrylic acid, 6 to 10 parts of alkyl phosphate, 6 to 10 parts of sodium alkylarysulfonate, 1 to 5 parts of cocoanut fatty acid diethanolamide, 4 to 8 parts of trihydroxyethyl methyl ammonium methosulfate, 4 to 8 parts of lauryl sodium sulfate, 2 to 6 parts of sesame oil, 1 to 5 parts of tea tree oil, and 80 to 120 parts of deionized water. The formula of the ceramic cleaning agent is reasonable; the ceramic cleaning agent is capable of cleaning stubborn stains on ceramic tile surfaces or in ceramic tile gaps rapidly and completely. The ceramic cleaning agent can be used for removing lime stains, cement stains, joint mixture stains, water rust, welding stains, aluminium scratches, metal scratches, black stains, mildew stains, water stains, paint stains, glue stains, and heavy oil stains rapidly because of excellent osmotic force of the ceramic cleaning agent; skin damage is not caused; the ceramic cleaning agent is harmless on human body, and is capable of satisfying environmental protection requirements.

Owner:陈 明志

Nonmetal electrode material of vanadium redox battery and preparation method thereof

InactiveCN102340009ACompact structureWon't fall offCell electrodesLow-density polyethyleneVanadium redox battery

The invention discloses a nonmetal electrode material of a vanadium redox battery and a preparation method thereof. The nonmetal electrode material comprises the following raw materials in a prescription: 10-30% of high-density polyethylene, 20-40% of low-density polyethylene, 1-3% of a mixture of calcium stearate and zinc stearate, 20-40% of electroconductive carbon black, 10-30% of graphite, 8-12% of ethylene-octylene copolymer, 2-5% of sodium alkylarysulfonate, 2-5% of polyoxyethylene fatty alcohol ether and 1-3% of stearic acid. A preparation process comprises the step of uniform mixing and milling to prepare the electrode material. The nonmetal electrode material disclosed by the invention has the advantages of compacter material structure, no falling-off, no pollution to electrolyte, good machine-shaping performance, breakdown difficulty, long service life, easily obtainable raw materials, low price, simple preparation method, no toxicity, no pollution, and suitability to mass popularization and application.

Owner:陶淞祥

Antiviral healthy plant water-based paint and preparation method thereof

PendingCN108774466AReduce concentrationIncreased durabilityAntifouling/underwater paintsPaints with biocidesCelluloseWater based

The invention discloses an antiviral healthy plant water-based paint and a preparation method thereof. The antiviral healthy plant water-based paint is prepared from the following components by weightpercentage: 8-35% of water, 0.2-3% of texanol ester alcohol, 0.5-3% of propylene glycol, 0.05-0.5% of organosilicon, 0.05-1% of polycarboxylic acid ammonium salt, 0.05-1.1% of isothiazolinone, 0.05-1.1% of sodium alkylarylsulfonate, 0.1-0.5% of cellulose, 0-30% of titanium dioxide, 3-40% of latex, 4-32% of vegetable gelatin powder, 0.1-3% of plant extracted essence, 0.24-1% of polyacrylate, 0.1-5% of new nanometer materials, 5-36% of modified talcum powder and 0-20% of mill base. The paint film provided by the invention has the following functions: 1: killing bacteria adhered to the surface of the film, effectively reducing concentration of bacteria in the space, and reducing the risk of diseases caused by inhalation of bacteria; 2. prolonging the persistent effectiveness to be tn years.

Owner:广东维拓化工股份有限公司

Soft-type clothes detergent

InactiveCN104911046ADeodorizationIn addition to sterilizationSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsFiberSulfate

The invention relates to the technical field of living goods, in particular to soft-type clothes detergent. The clothes detergent comprises, by weight, 8-12 parts of fatty alcohol-polyoxyethylene ether, 6-10 parts of fatty alcohol sulfate monoethanol amine salt, 4-8 parts of glycerin monostearate, 4-8 parts of three hydroxyethyl methyl quaternary ammonium sulfate, 2-6 parts of sodium alkylarysulfonate, 2-6 parts of sodium carboxymethylcellulose, 1-5 parts of ethanediol, 1-3 parts of cinnamon oil, 5-10 parts of tea seed powder, 5-10 parts of algal polysaccharides and 80-120 parts of deionized water. The soft-type clothes detergent is reasonable in formula, good in decontamination effect, strong in decontamination strength, little in bubbles, incapable of damaging clothes, soft and free of deformation in clothes after washing, non-irritating, non-toxic, non-harmful for skin and vivo environment, capable of conforming the requirements of the environmental protection and widely applicable to washing of various clothes such as velveteen, fibers and silk.

Owner:陈 明志

Multipurpose oil stain detergent

InactiveCN104893854AEfficient removalGood degreasing effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPlastic materialsIrritation

The invention relates to the technical field of articles for daily life, in particular to a multipurpose oil stain detergent. The multipurpose oil stain detergent is prepared by using the following raw materials in parts by weight: 8-12 parts of acrylic acid, 8-10 parts of alkyl phosphate, 6-10 parts of sodium alkylarysulfonate, 4-8 parts of tris(hydroxyethyl)methyl quaternary amine methylsulfate, 4-8 parts of lauryl sodium sulfate, 2-6 parts of tea seed powder, 1-5 parts of tea tree oil, 0.2-0.6 part of chitosan-graphene composite material and 80-120 parts of deionized water. The multipurpose oil stain detergent provided by the invention has the advantages that the formula is reasonable, edible oil, engine oil and other oil stains on clothes, metal parts, oil smoke exhausting stoves, tile walls, plastic materials and the like can be effectively removed, the stain removing capability is strong, the foam is less, the clothes, metal parts and the like are not damaged, no irritation and toxicity exist, skins are not injured, no harm is caused to human bodies and environments, and the environmental protection requirements are satisfied.

Owner:陈 明志

Heat-resistant oil solution for textile fibers

The invention relates to a heat-resistant oil solution for textile fibers, which is prepared from the following raw materials in parts by weight: 4-6 parts of sodium alkylarysulfonate, 5-8 parts of polyvinylpyrrolidone, 4-6 parts of sodium 2-ethylhexyl sulfate, 2-7 parts of dipolyethylenediamine, 5-8 parts of nonionic emulsifier, 6-10 parts of methyl acrylate, 5-9 parts of ammonium bicarbonate, 3-6 parts of fatty alcohol polyethenoxy ether, 3-7 parts of peregal, 4-6 parts of sodium sulfite, 8-14 parts of polyvinyl alcohol, 3-5 parts of diffusant N, 8-10 parts of alkane sulfonate and 4-7 parts of long chain alcohol. The heat-resistant oil solution for textile fibers can endow fibers with certain antistatic property, has favorable heat resistance, does not have the phenomenon of yellowing, volatilization or smoking when being heated, and has longer service life.

Owner:QINGDAO DONGCHANGRUI TEXTILE

Smoothing agent for spinning

The invention discloses a smoothing agent for spinning. The smoothing agent is prepared from the following components: wool grease, sodium alkylarysulfonate, sodium hydrogen phosphate, trimethylolpropane fatty acid ester, dimethyl silanol, paraffin, sodium hydrogen phosphate and water. The smoothing agent disclosed by the invention has the beneficial effects that the smoothing agent has a good smoothing effect, enables cellosilk to obtain excellent smoothness and softness, and also has good thermal stability and oxidation resistance.

Owner:苏州极地实业有限公司

Novel rapid penetrating agent used for leather

The invention discloses a novel rapid penetrating agent used for leather. The novel rapid penetrating agent comprises, by weight, 6-9 parts of sodium dodecyl benzene sulfonate, 2-4 parts of fatty alcohol polyoxyethylen ether, 10-14 parts of linolenic acid, 3-6 parts of di-n-octyl succinate sodium salt, 40-60 parts of water, 15-17 parts of styrene, 3-6 parts of ethylenediaminetetraacetic acid, 2-5 parts of sodium alkyl aryl sulfonate, 1-6 parts of fatty alcohol succinate, 12-16 parts of organic alcohol amine, 4-9 parts of sucrose ester and 12-15 parts of N-(phosphonomethyl)glycine 2-propylamine. The novel rapid penetrating agent used for leather is extremely high in permeability and strong in basicity and high in penetrating speed, the comprehensive performance of the penetrating agent is also effectively improved, and the penetrating performance of leather dye can be obviously increased; and raw materials required for preparing the penetrating agent are low in price and easy to obtain, the preparation process is simple, and requirements for production devices are low.

Owner:董荣琴

Electric flat carriage

InactiveCN105483673AExcellent abrasion resistanceImprove corrosion resistanceMetallic material coating processesCalcium borogluconateCorrosion

The invention discloses an electric flat carriage which comprises a metal spindle, wherein the metal spindle is subjected to surface treatment. The surface treatment comprises the following steps: 1. taking 17 parts by mass of citric acid, 1-2 parts by mass of ethidene diamine, 1.6 parts by mass of boric acid, 3.1 parts by mass of calcium gluconate, 4.2 parts by mass of sodium molybdate, 1.2 parts by mass of sodium alkylarysulfonate, 2.4 parts by mass of phenyl naphthylamine and 1.6 parts by mass of sodium hypochlorite, mixing for 2 hours at the temperature of 75 DEG C so as to prepare a metal surface treatment agent; 2. mixing 26 parts by mass of the metal surface treatment agent with 47 parts by mass of deionized water so as to prepare a surface treatment working solution; and 3. heating the surface treatment working solution to 40 DEG C, and putting a metal shell into the surface treatment working solution for 35 minutes. According to the invention, the metal spindle is subjected to surface treatment, and the electric flat carriage has excellent performances of abrasion resistance, corrosion resistance, antioxidation, heat resistance, cold resistance and weather resistance.

Owner:常熟市常宝电动过跨平车厂

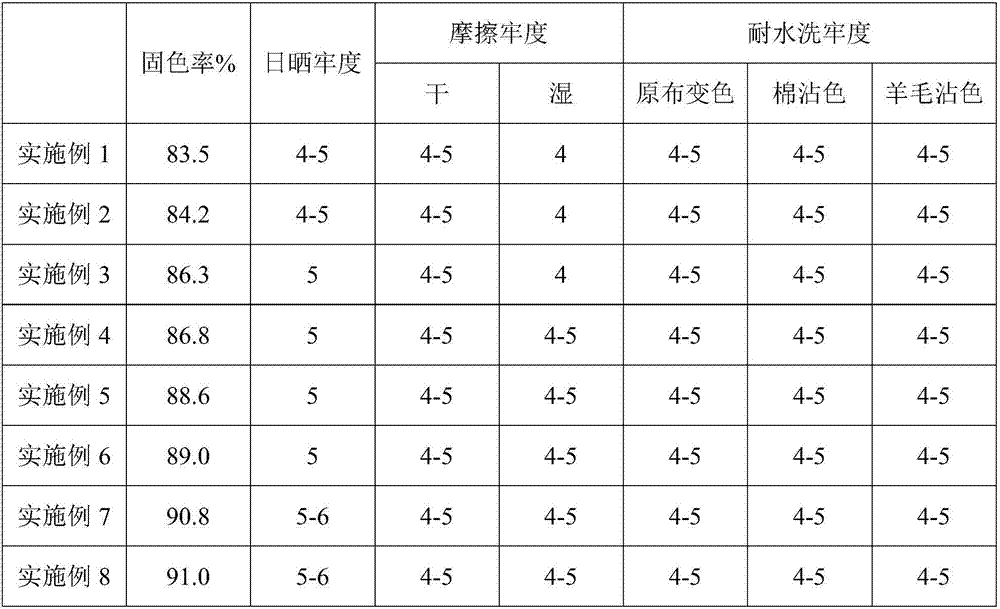

Environmentally-friendly dyeing liquid for uniformly dyeing ultrafine fiber leather

InactiveCN107034697AImprove uniformityHigh color fastnessDyeing processLinear low-density polyethyleneSucrose

The invention discloses an environmentally-friendly dyeing liquid for uniformly dyeing ultrafine fiber leather. The dyeing liquid comprises, by weight, 5-110 parts of a dye, 10-120 parts of dimethylformamide, 3-30 parts of linolenic acid, 10-50 parts of butyl acetate, 1-15 parts of polyvinylpyrrolidone, 5-35 parts of styrene, 0-110 parts of sodium lignosulfonate, 5-30 parts of terpene resin, 0.5-15 parts of sodium hexametaphosphate, 3-25 parts of linear low-density polyethylene, 0-120 parts of tannin extract, 1-22 parts of hydrogenated rosin, 1-15 parts of sodium alkylaryl sulfonate, 1-20 parts of ceramic micro-powder, 1-25 parts of sucrose ester, 0.5-45 parts of polyacrylamide and 200-600 parts of water.

Owner:DONGGUAN KEDI IND CO LTD

Multifunctional compound type liquid detergent for daily use chemicals

InactiveCN108277100AReduce usageLow costCationic surface-active compoundsAnionic-cationic-non-ionic surface-active compoundsAmylaseAdditive ingredient

The invention discloses a multifunctional compound type liquid detergent for daily use chemicals. The detergent is formed by mixing the following ingredients in percentage by weight: 10-30% of tea tree oil, 4-30% of methyl ester sulfonate, 5-30% of sodium diethylhexyl sulfosuccinate, 1-10% of sodium lauroyl sarcosine, 1-10% of sodium N-Lauroylglutamate, 1-10% of hyperbranched dimeric quaternary ammonium salt, 4-30% of alkyl polyglucoside, 30-70% of purified water, 4-30% of alkyl aryl sodium sulfonate, 0.1-1% of protease, 0.1-1% of lipase, 0.1-1% of amylase, and 0.1-1% of cellulase. The mild clean materials not causing dioxane are optimized and blended with bio-enzymes, the hyperbranched dimeric quaternary ammonium salt and the tea tree oil, bacteria and mites are removed by 99%, the liquiddetergent achieves the multiple effects that the liquid detergent reaches the actually non-toxic grade, is not irritant to the skin, does not contain dioxane or additionally added chemical preservatives, and has a good decontamination effect.

Owner:张宏坤

Flame retardant zipper

InactiveCN104352032AStrong weather resistanceFlame retardantSlide fastenersFibre typesKerosenePolyethylene glycol

The invention discloses a flame retardant zipper. The flame retardant zipper comprises chain belts and chain teeth; chain tooth protective layers coat the chain teeth; chain belt protective layers are formed by the following components, by weight part, one part of sodium alcohol ether sulphate, five parts of potassium chloride, two parts of lauryl sodium sulfate, six parts of ammonium sulfate, two parts of sodium alkylarysulfonate, three parts of artificial mica, three parts of citric acid, one part of diammonium hydrogen phosphate and one part of sodium hexametaphosphate; the chain tooth protective layers are formed by the following components, by weight part, two parts of block polyoxyethylene-poly propylene ether oxygen, six parts of kerosene, six parts of zinc oxide, one part of trisodium phosphate, four parts of sodium tripolyphosphate, three parts of polyoxyethylene stearates, five parts of vaseline, one part of acrylamide, three parts of sodium molybdate, two parts of polyethylene glycol and one part of sodium hexametaphosphate. Protective layers coat the chain belts and the chain teeth and accordingly the zipper is strong in weather resistance, is corrosion resistant and has a flame retardant effect.

Owner:江苏汇源拉链制造有限公司

Uniform dyeing method of textile

The invention discloses a uniform dyeing method of textile. The uniform dyeing method comprises steps as follows: the textile is put in a dye vat at a bath ratio of 3:8, the water temperature is increased to 65 DEG C, 3 g / L of coco trimethyl ammonium chloride, 12 g / L of aluminum sulfate and 8 g / L of coconut diethanol amide are added, the temperature is increased to 91 DEG C, heat preservation is performed for 65 min, and preliminary dyeing is finished; and textile after preliminary dyeing is put into a dye vat at a bath ratio of 3:5, 6 g / L of sodium alkylarysulfonate, 19 g / L of natural dye and 4 g / L of cocamidopropyl betaine are added when the water temperature is increased to 57 DEG C, PH is regulated to 2.9, the temperature is increased to 70 DEG C at the temperature increase speed of 7 DEG C / min, heat preservation is performed for 3 hours, and dyeing is finished. The dyed textile is environment-friendly, dyeing is uniform, and fading is prevented.

Owner:MF

Production process of punching part

InactiveCN105506594AExcellent abrasion resistanceImprove corrosion resistanceMetallic material coating processesWorking fluidPetroleum

The invention discloses a production process of a punching part. The production process comprises a punching part surface treatment step; and the surface treatment includes the following steps: 1) 1-2 mass parts of 1, 6-hexylidene triamine pentomethene phosphonic acid, 3.3 mass parts of sodium alginate, 1.5 mass parts of ethoxyethanol, 1.8 mass parts of petroleum sodium sulfonate, 0.9 mass part of lignosulfonate , 1.5 mass parts of alkyl aryl sodium sulfonate and 3.5 mass parts of oxalic acid are added in 15.1 mass parts of de-ionized water for uniformly stirring to prepare a surface treatment working fluid; 2) the surface treatment working fluid is heated up to 60 DEG C; and 3) the punching part is put in the surface treatment working fluid for dipping by 19 minutes, and is taken out for drying. According to the production process of the punching part, the punching part is excellent in friction resistance, corrosion resistance, oxidation resistance, heat resistance, cold resistance and weather resistance through surface treatment.

Owner:SUZHOU YIDIAN POWER TECH CO LTD

General coating and preparation method for preparing light-color and dark-color general coating

InactiveCN106634335AEasy to prepareEasy to produceAntifouling/underwater paintsPaints with biocidesCelluloseCarboxylic acid

The invention discloses a general coating and a preparation method for preparing a light-color and dark-color general coating. The general coating comprises the following components by weight percent: 10-18% of water, 0.3-3% of texanol, 0.35-3% of propylene glycol, 0.05-0.5% of organic silicon, 0.05-1% of polycarboxylic ammonium, 0.05-1.1% of isothiazolinone, 0.05-1.1% of sodium alkylarylsulfonate, 0.1-0.5% of cellulose, 0-30% of titanium dioxide, 5-35% of acrylate emulsion, 5-35% of acrylic emulsion, 0.24-1% of polyacrylate, 5-36% of modified talcum powder and 0-20% of color paste. The general coating provided by the invention is suitable for the substrate surface decoration of indoor and outdoor concrete structures, bamboo structure and steel structure and has the advantages of excellent weather fastness, pollution resistance, brushing resistance, wide application scope, simple preparation method, easiness in production and easiness in popularization.

Owner:广东维拓化工股份有限公司

After-finishing process for wool fabric

InactiveCN105386293AExcellent flame retardantGood antibacterialAnimal fibresLinear alkylbenzeneRhizome

The invention discloses an after-finishing process for a wool fabric. The process comprises the following steps: 1) adding 1 to 2 parts by mass of mica, 1.8 parts by mass of linear alkyl benzene sulphonic acid, 2.2 parts by mass of catnip volatile oil and 1.9 parts of by mass of sodium chloride into 33 parts by mass of deionized water and carrying out uniform mixing under stirring; 2) then slowly adding 3.6 parts by mass of sodium alkyl aryl sulfonate, 2.8 parts by mass of 1,2-propylene glycol, 3.4 parts by mass of dibutyl ester and 1.7 parts by mass of bock greenbrier rhizome extract at the same time and continuing stirring until uniform mixing is realized so as to obtain a finishing agent; and 3) subjecting the fabric to padding in impregnation liquid containing the finishing agent and then drying the fabric at a constant temperature. The wool fabric processed by using the after-finishing process has excellent flame retardation, bacterium resistance, crease resistance and antistatic performance and good washing fastness.

Owner:常熟市华谊织造有限公司

Finishing process for cotton and linen fabric

InactiveCN105350336AGood antibacterialImprove mildew resistanceBiochemical fibre treatmentHeat resistant fibresHydrogen phosphateDiammonium phosphate

The invention discloses a finishing process for cotton and linen fabric. The finishing process comprises the following steps: (1) sequentially feeding the following raw materials in parts by weight: 1-2 parts of sodium alkylarysulfonate, 0.9 part of vermiculite power, 2.2 parts of dimethicone and 1.3 parts of prochloraz to 20 parts by mass of deionized water, and mixing and stirring the raw materials evenly; (2) simultaneously feeding the following raw materials in parts by weight: 0.9 part of fluorophenoxy phenylsilane, 1.2 parts of diammonium hydrogen phosphate, 0.2 part of acetylene black and 1.7 parts of di(butter acylamino ethyl)-2-hydroxy ethyeneamine, and further stirring the raw materials until the raw materials are fully mixed evenly, so as to prepare a finishing liquid; and (3) carrying out padding treatment on the fabric in the finishing liquid, and taking out and drying the fabric at a constant temperature. According to the finishing process for the cotton and linen fabric, the finished fabric has excellent antibacterial property, anti-mold property, flame retardant property, mothproof property and antistatic property, high washability and soft hand feeling.

Owner:CHANGSHU ZHONGHONG KNITTING MILL

Smoothing agent for spinning

The invention discloses a smoothing agent for spinning. The smoothing agent comprises the following components: lanolin, sodium alkylarysulfonate, dibasic sodium phosphate, trimethylolpropane fatty acid ester, dimethyl silanol, paraffin, dibasic sodium phosphate and water. The smoothing agent disclosed by the invention has the benefits that the smoothing agent has a good smoothing effect, can ensure that fiber filaments have very excellent smoothness and softness, and has good thermal stability and oxidation resistance.

Owner:SUZHOU LEO BIOTECH

Light-colored waterborne heat-insulation coating and method for preparing same

InactiveCN106634299AGood weather resistanceImprove water resistanceAntifouling/underwater paintsPaints with biocidesOrganosiliconVariospora

The invention discloses light-colored waterborne heat-insulation coating and a method for preparing the same. The light-colored waterborne heat-insulation coating comprises, by weight, 10-30% of water, 1-3% of texanol, 1-3% of propylene glycol, 0.1-0.5% of organosilicon, 0.05-1% of polycarboxylic acid ammonium salt, 0.03-1.1% of isothiazolinone, 0.03-1.1% of sodium alkylarysulfonate, 10-30% of titanium dioxide, 8-18% of high-reflection macromolecular compounds, 5-35% of acrylic acid emulsion, 0.24-1% of polyacrylate, 5-35% of calcium carbonate, 0-10% of color paste and 0.1-0.5% of celluloses. The light-colored waterborne heat-insulation coating and the method have the advantages that the light-colored waterborne heat-insulation coating is applicable to carrying out heat-insulation and anti-seepage treatment on roofs, balconies and cement asbestos tile surfaces, can be used for heat-insulation cooling treatment on metal tile surfaces and outdoor metal storage tanks, is excellent in weather resistance, pollution resistance, abrasion resistance and scrub resistance, is waterborne, environmentally friendly, non-toxic and tasteless and can be easily, conveniently and quickly constructed, energy can be obviously saved, power consumption can be obviously reduced, and the temperatures of coatings can be reduced by 10 DEG C at least under the burning sun; the light-colored waterborne heat-insulation coating can be adjusted to have diversified light colors according to decoration aesthetic requirements and has durable heat-insulation functions.

Owner:广东维拓化工股份有限公司

Clothes washing agent

InactiveCN105039012AGood decontamination effectStrong decontaminationDetergent dyesAnionic-cationic-non-ionic surface-active compoundsFiberFatty alcohol

The invention relates to the technical field of household articles, and specifically relates to a clothes washing agent. The clothes washing agent comprises the following raw materials in parts by weight: 8 to 12 parts of fatty alcohol polyoxyethylene ether, 6 to 10 parts of fatty alcohol sulfate monoethanolamine, 4 to 8 parts of glycerin monostearate, 4 to 8 parts of trihydroxyethyl methyl quaternary amine methyl sulfate, 2 to 6 parts of sodium alkyl aryl sulfonate, 2 to 6 parts of sodium carboxymethyl cellulose, 1 to 5 parts of glycol, 1 to 3 parts of cassia oil, and 80 to 120 parts of deionized water. The provided clothes washing agent has the advantages of reasonable formula, good decontamination effect, strong decontamination performance, little foam, and low production cost, does not harm the clothes and skin, is non-irritant, non-toxic, and harmless to the human body and environment, is accord with the environment protection requirements, and can be used to wash various clothes made of cotton, fiber, silk, and the like.

Owner:陈养生

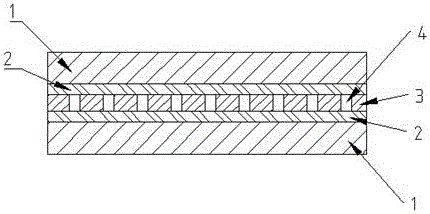

Copper-aluminum battery electrode and processing method thereof

The invention discloses a copper-aluminum battery electrode which comprises an electrode material, fiber nets, a current collector and nanopores, wherein the two sides of the current collector are coated with the fiber nets; the outer sides of the fiber nets are coated with the electrode material; the nanopores penetrating through the current collector are formed in the current collector; the electrode material consists of the following raw material in parts by weight: 40-60 parts of copper, 40-60 parts of aluminum, 20-35 parts of high density polyethylene, 15-30 parts of high-density polypropylene, 5-10 parts of polyvinyl butyral, 10-18 parts of carbon nanotubes, 2-6 parts of alkyl aryl sodium sulfonate, 1-5 parts of stearic acid, 15-30 parts of conductive carbon black, 5-10 parts of phenolic aldehyde, 1-4 parts of an adhesive and 10-15 parts of graphite. The nanopores are formed in the current collector of the copper-aluminum battery electrode, so that capacities on two sides can be supplemented by each other, the service life of the battery is prolonged, and the electrode material has the advantages of low resistance, good stability, large specific surface area and the like.

Owner:NINGGUO GUANNING ELECTRICAL APPLIANCE CO LTD

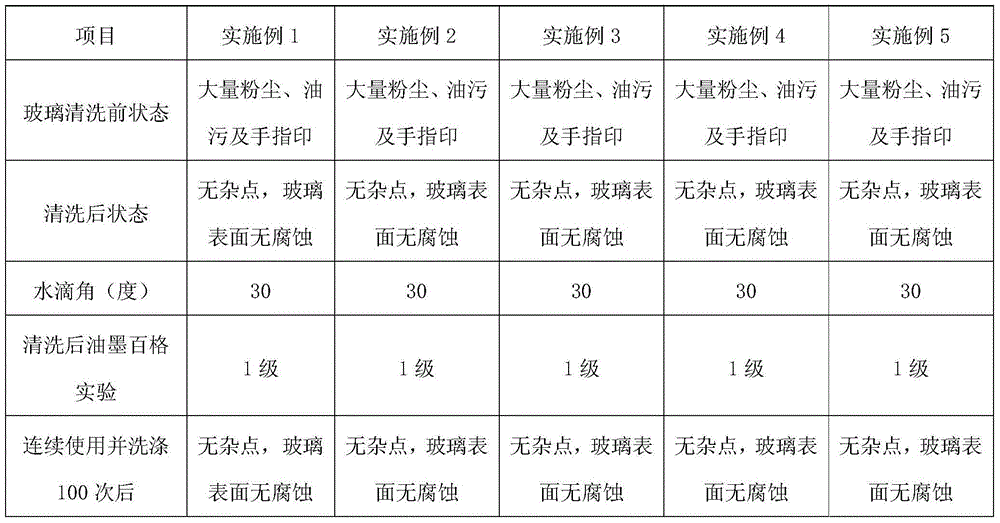

Glass cleaning agent and preparation method

ActiveCN103820246AGood removal effectNo noiseSurface-active detergent compositionsDetergent compounding agentsOXALIC ACID DIHYDRATEEthylenediamine

The invention discloses a glass cleaning agent and a preparation method thereof. The glass cleaning agent comprises the following ingredients in parts by weight: 8-12 parts of oxalic acid, 0.2-0.6 parts of sodium alkylarysulfonate, 2-5 parts of glycerol, 0.5-1 part of anhydrous calcium oxide, 0.5-1 part of magnesium sulfate, 0.1-0.5 parts of sodium-ethylenediamine-tetra-acetic acid, 1-4 parts of sodium pyrophosphate, 0.5-2 parts of tween 80, and 40-50 parts of deionized water. The preparation method comprises the steps of adding sodium alkylarysulfonate, anhydrous calcium oxide, magnesium sulfate, sodium-ethylenediamine-tetra-acetic acid, sodium pyrophosphate and tween 80 into the deionized water, heating to 60-70 DEG C, stirring to produce colloidal micel suspension, continuing to stir for 10-20min, adding oxalic acid and glycerol into the obtained suspension, heating to 80-90 DEG C and stirring for 15-30min. The glass cleaning agent can well clean dirt on the surface of glass and has no influence on the glass.

Owner:南通市通州区五接农业机电管理站有限公司

Sodium alkylarylsulfonate surfactant composition and its preparation and application

ActiveCN107670581ALow viscosityLow aromatic contentTransportation and packagingMixingBenzeneReverse order

The invention provides a sodium alkylarylsulfonate surfactant composition and its preparation and application. The method comprises mixing a raw material 1 and a raw material 2 to obtain a mixed material, wherein the raw material 1 comprises one or more of reverse order dewaxed oil or distillate from a decompression second line, reverse order dewaxed oil or distillate from a decompression third line and reverse order dewaxed oil or distillate from a decompression forth line, the raw material 2 comprises one or more of light alkyl benzene, heavy alkyl benzene 1# and heavy alkyl benzene 2#, a weight ratio of each ingredients in the raw material 1 is 5-95wt% and a weight ratio of each ingredients in the raw material 2 is 5-95wt%, carrying out sulfonation treatment on the mixture through SO3 gas to obtain the sulfonated product and neutralizing the sulfonated product until system pH is 7-10 through a sodium hydroxide aqueous solution.

Owner:PETROCHINA CO LTD

Improved disinfection solution for livestock

InactiveCN104824062AEasy to disinfectImprove the bactericidal effectBiocideDisinfectantsBiotechnologyIron sulfate

The invention relates to an improved disinfection solution for livestock, which is prepared from the following raw materials in parts by weight: 9-21 parts of sodium alkylarysulfonate, 3-5 parts of disodium hexadecyl diphenyl ether disulfonate, 4-6 parts of ethanol, 6-8 parts of zinc sulfate, 7-12 parts of calamine, 2-4 parts of herba schizonepetae, 5-6 parts of gynura bicolor, 4-8 parts of glabrous greenbrier rhizome, 7-11 parts of sorbitol, 6-8 parts of ethylenediamine tetraacetic acid, 12-18 parts of polyferric sulfate, 6-12 parts of potassium permanganate and 4-7 parts of propanediol. The improved disinfection solution for livestock has the advantages of higher disinfection and sterilization effects, no residue, no corrosion and no irritation, and is safe for people and animals.

Owner:QINGDAO DONGCHANGRUI TEXTILE

Smoothing agent for textile

The invention discloses a smoothing agent for textile. The smoothing agent is prepared from the following components of lanolin, sodium alkylarylsulfonate, sodium hydrogen phosphate, trihydroxymethyl propane fatty acid ester, dimethylsilanol, paraffin, sodium hydrogen phosphate and water. The smoothing agent has the beneficial effects that the smoothing effect is better, and the fiber yarn has excellent smoothing property and softness; the good heat stability and anti-oxidizing property are realized.

Owner:苏州卡佩罗尔高分子材料有限公司

Preparation method for crease-resistant finishing liquid for fabrics

InactiveCN105401428AImprove hydrophilicityImprove permeabilityHeat resistant fibresWrinkle resistant fibresPolyethylene glycol monomethyl etherIon

A disclosed preparation method for crease-resistant finishing liquid for fabrics comprises the following steps: 1) successively adding 1-2 parts by weight of sodium alkyl aryl sulfonate, 2.3 parts by weight of polyacrylic acid, 1.3 parts by weight of octamethylcyclotetrasiloxane, 0.9 part by weight of shea butter into 15 parts by mass of deionized water, and stirring uniformly; 2) and then simultaneously pouring 1.5 parts by weight of wild chrysanthemum flower extraction liquid, 0.9 part by weight of sodium chlorite, 1.3 parts by weight of poly(ethyleneglycol) methyl ether methacrylate, and 0.8 part by weight of ethylenebis(oxyethylenenitrilo)tetraacetic acid, continuing to stir until the mixture is uniformly mixed, so as to prepare the finishing liquid. The prepared finishing solution is good in hydrophilicity and good in permeability. The fabrics finished by using the finishing solution possesses excellent static electricity resistance, flame resistance, moth resistance, mildew resistance and bacteria resistance, and is strong in washing fastness and soft in handfeel.

Owner:成路凯尔服装(苏州)有限公司

Preparation method of master batch for PBT fibers

InactiveCN109054312AImproves UV resistanceSolving spinning processing problemsPigment addition to spinning solutionMonocomponent polyesters artificial filamentFiberPhosphate

The invention discloses a preparation method of master batch for PBT fibers. The master batch is prepared from the following components in parts by weight: 23 parts of PBT, 12 parts of pigments, 1.4 parts of cobalt naphthenate, 2.3 parts of aminotriacetic acid, 3.1 parts of sulfamic acid, 0.8 part of zinc dihydrogen phosphate, 1.5 parts of sodium fluosilicate, 2.6 parts of polyoxyethylene oleate,0.9 part of alkyl aryl sodium sulfonate, 1.1 parts of sodium persulfate, 2.3 parts of nonylphenol ethoxylate carboxylate, and 1.9 parts of N-methyl pyrrolidone. The master batch prepared by the invention is suitable for the PBT fibers, and the master batch is good in ultraviolet resistance.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

Biological disinfectant for food production workshop

InactiveCN103598209ANot easy to produceNon-irritatingBiocideDisinfectantsDisinfectantHazardous substance

The invention discloses a biological disinfectant for a food production workshop. The biological disinfectant comprises the following components by weight: 0.01-0.02 part of alkaline protease, 37-48 parts of Sodium Alkyl Aryl Sulfonate, 15-29 parts of trisodium phosphate, 12-31 parts of sodium alkyl benzene sulfonate, 30-45 parts of ethanol, 5-10 parts of sorbitol, 0.001-0.005 part of lysozyme and 100 parts of distilled water. The biological disinfectant is strong in sterilization specificity, mild in action conditions and fast in action speed, does not produce drug-resistant strains, can be dissolved in water easily, has no stimulation to articles and is safe for use. The biological disinfectant particularly does not produce harmful substances residual in foods. A preparation method is simple, is suitable for sterilization and sanitation for food processing industry, food equipment, food processing environment, fruits and vegetables in family life and surfaces of common articles.

Owner:QINGDAO SANDING SANITARY PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com