Glass cleaning agent and preparation method

A glass cleaning agent, weight technology, applied in detergent compositions, detergent compounding agents, chemical instruments and methods, etc., can solve problems such as harming users, rough glass surface, and polluting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

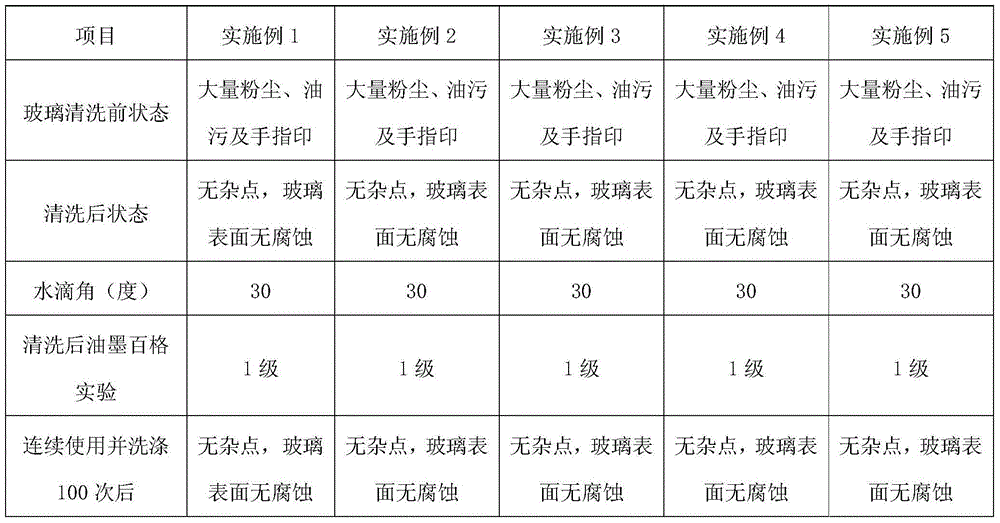

Examples

Embodiment 1

[0013] A glass cleaning agent, comprising by weight components: 8 parts of oxalic acid, 0.2 part of sodium alkylarylsulfonate, 2 parts of glycerin, 0.5 part of anhydrous calcium oxide, 0.5 part of magnesium sulfate, and 0.1 part of sodium edetate 1 part, 1 part of sodium pyrophosphate, 800.5 parts of Tween, 40 parts of deionized water.

[0014] Described glass cleaning agent is prepared according to the following steps:

[0015] (1) Weigh each component according to parts by weight;

[0016] (2) Add sodium alkylaryl sulfonate, anhydrous calcium oxide, magnesium sulfate, sodium ethylenediamine tetraacetate, sodium pyrophosphate and Tween 80 into deionized water, heat to 60°C, and stir until a colloidal state is produced Suspension of molecular clusters, continue to stir for 10 minutes;

[0017] (3) Add oxalic acid and glycerin to the suspension obtained in step (2), continue to heat up to 80°C, and stir for 15 minutes.

Embodiment 2

[0019] A glass cleaning agent, comprising by weight components: 10 parts of oxalic acid, 0.3 part of sodium alkylarylsulfonate, 3 parts of glycerin, 0.6 part of anhydrous calcium oxide, 0.8 part of magnesium sulfate, and 0.2 part of sodium edetate 1 part, 1 part of sodium pyrophosphate, 801.5 parts of Tween, 46 parts of deionized water.

[0020] Described glass cleaning agent is prepared according to the following steps:

[0021] (1) Weigh each component according to parts by weight;

[0022] (2) Add sodium alkylaryl sulfonate, anhydrous calcium oxide, magnesium sulfate, sodium ethylenediamine tetraacetate, sodium pyrophosphate and Tween 80 into deionized water, heat to 65°C, and stir until a colloidal state is produced Suspension of molecular clusters, continue to stir for 12 minutes;

[0023] (3) Add oxalic acid and glycerin to the suspension obtained in step (2), continue to heat up to 82°C, and stir for 18 minutes.

Embodiment 3

[0025] A glass cleaning agent, comprising by weight components: 11 parts of oxalic acid, 0.4 parts of sodium alkylaryl sulfonate, 3.5 parts of glycerin, 0.7 parts of anhydrous calcium oxide, 0.9 parts of magnesium sulfate, and 0.3 parts of sodium edetate 2 parts, 2 parts of sodium pyrophosphate, 801.6 parts of Tween, 47 parts of deionized water.

[0026] Described glass cleaning agent is prepared according to the following steps:

[0027] (1) Weigh each component according to parts by weight;

[0028] (2) Add sodium alkylaryl sulfonate, anhydrous calcium oxide, magnesium sulfate, sodium ethylenediamine tetraacetate, sodium pyrophosphate and Tween 80 into deionized water, heat to 65°C, and stir until a colloidal state is produced Suspension of molecular clusters, continue to stir for 18 minutes;

[0029] (3) Add oxalic acid and glycerin to the suspension obtained in step (2), continue to heat up to 85°C, and stir for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com