Copper-aluminum battery electrode and processing method thereof

A battery electrode, copper-aluminum technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of shortening battery life, capacity loss, and the capacity of electrode materials cannot complement each other, so as to improve the service life, Good stability and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

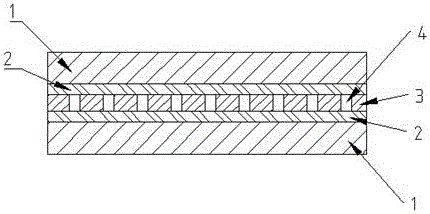

[0025] like figure 1 As shown, the present invention adopts the following technical solutions to achieve: the copper-aluminum battery electrode includes an electrode material 1, a fiber mesh 2, a current collector 3 and a nanopore 4, and both sides of the current collector 3 are coated with a fiber mesh 2, and the fiber mesh 2. The outer side is coated with electrode material 1, and the current collector 3 is processed with nanopores 4 penetrating through the current collector 3. The electrode material is composed of the following raw materials in parts by weight: 40-60 parts of copper, 40-60 parts of aluminum, high-density polymer 20-35 parts of ethylene, 15-30 parts of high-density polypropylene, 5-10 parts of polyvinyl butyral, 10-18 parts of carbon nanotubes, 2-6 parts of sodium alkylaryl sulfonate, 1 part of stearic acid ~5 parts, 15~30 parts of conductive carbon black, 5~10 parts of phenolic formaldehyde, 1~4 parts of binder and 10~15 parts of graphite.

[0026] As a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com