High-temperature-resistant oil base drilling fluid emulsifier

An oil-based drilling fluid and emulsifier technology, which is applied in the field of oil-based drilling fluid, can solve problems such as unstable performance, high emulsifier price, and single emulsifier variety, and achieve good stability, good compatibility, and strong anti-pollution ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Emulsifier A: The preparation process is: lauryl alcohol first undergoes substitution reaction with ethylene oxide, the reaction molar ratio is 1 to 3:1, and the reaction conditions are: reaction at a temperature of 100°C to 150°C for 2 to 5 hours. The reaction product is further added by addition polymerization to form an ether. When 10-15 are added, emulsifier A is obtained. The prepared emulsifier A showed better emulsifying ability, wetting ability and biodegradability. The lauryl alcohol in the above preparation process can also be replaced with oleyl alcohol, cyclohexanol, and stearyl alcohol.

[0015] Emulsifier B: three raw materials: iron petroleum sulfonate, sodium alkylbenzene sulfonate, sodium alkyl succinate sulfonate at a weight ratio of 2:1:1, stir and mix uniformly at a high speed at 60°C to obtain an emulsifier B. The prepared emulsifier B is a good oil-soluble emulsifier and dispersant.

[0016] Emulsifier C is zinc stearate, which has good thermal stabil...

Embodiment 2

[0026] Emulsifier A: palmityl alcohol first undergoes a substitution reaction with ethylene oxide, the reaction molar ratio is 1 to 3:1, and the reaction conditions are: 100°C to 150°C for 2 to 5 hours. The reaction product is further added into ether by addition polymerization. When 10-15 are added, the product emulsifier A is obtained. The prepared emulsifier A showed better emulsifying ability, wetting ability and biodegradability. The lauryl alcohol in the above preparation process can also be replaced with oleyl alcohol, cyclohexanol, and stearyl alcohol.

[0027] Emulsifier B: two raw materials: iron petroleum sulfonate and sodium alkylbenzene sulfonate in a weight ratio of 2:1, stir and mix uniformly at a high speed at 60°C to obtain emulsifier B. The prepared emulsifier B is a good oil Soluble emulsifier and dispersant.

[0028] Emulsifier C is polyoxyethylene stearate, which has good thermal stability.

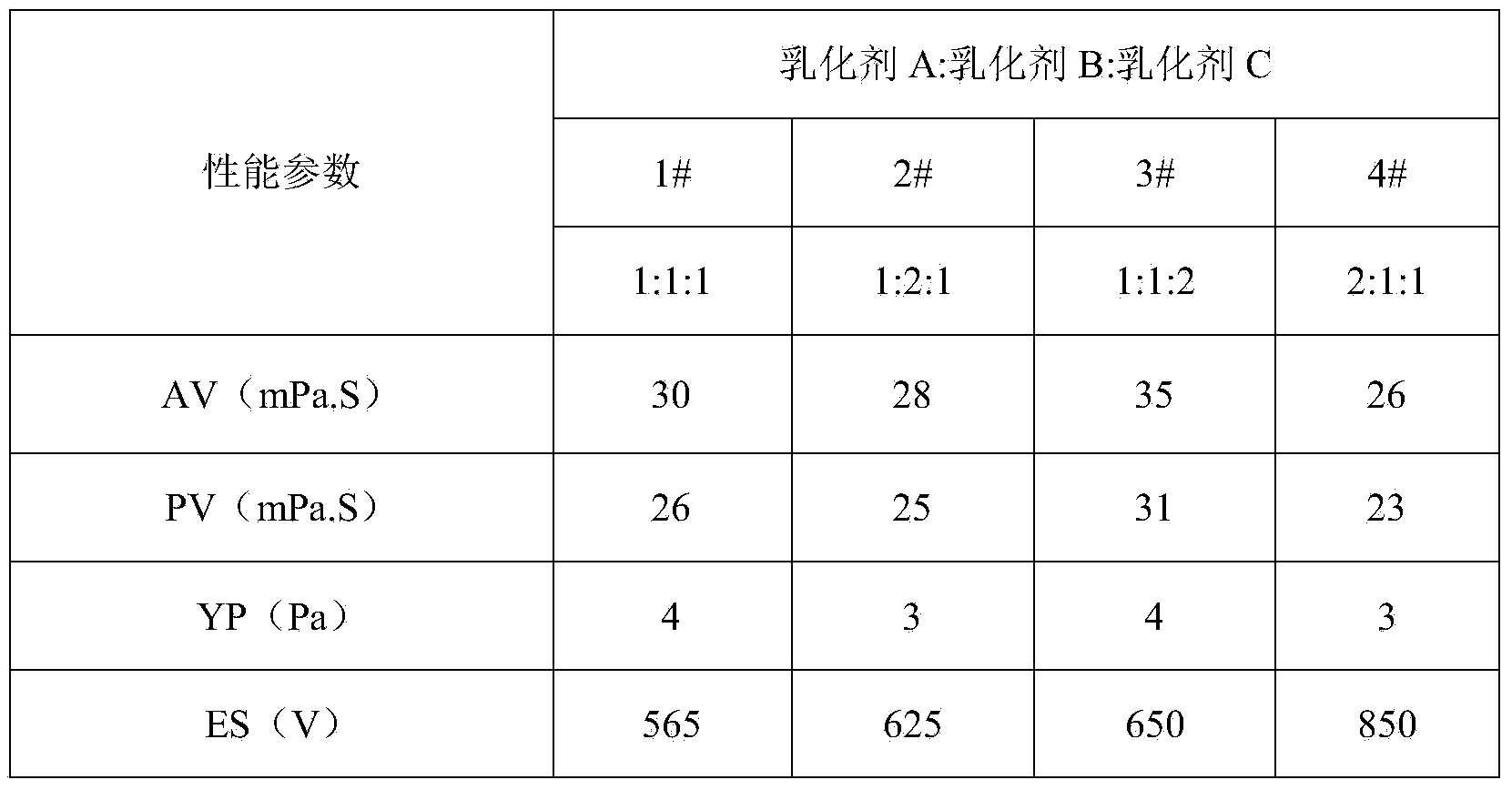

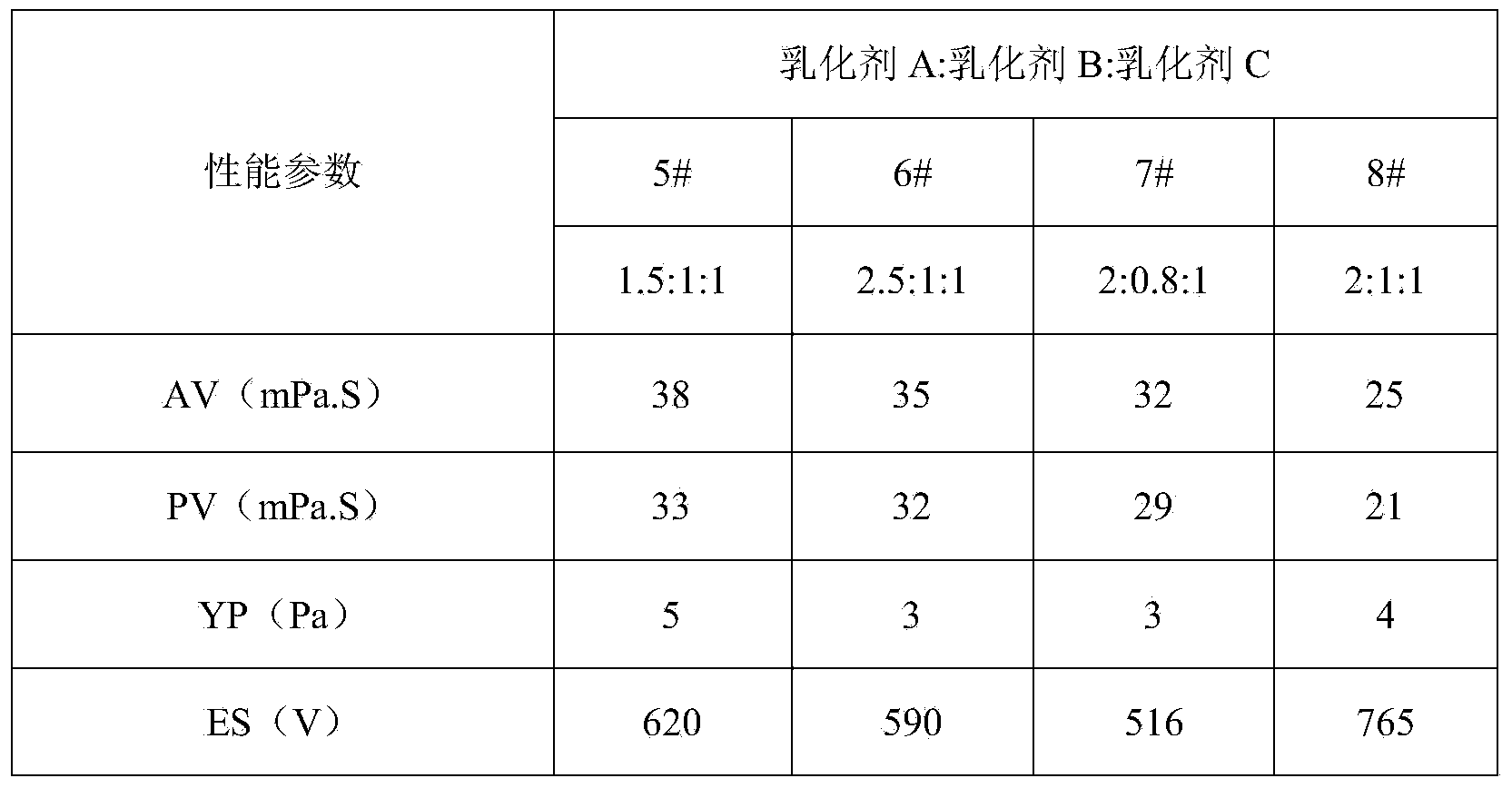

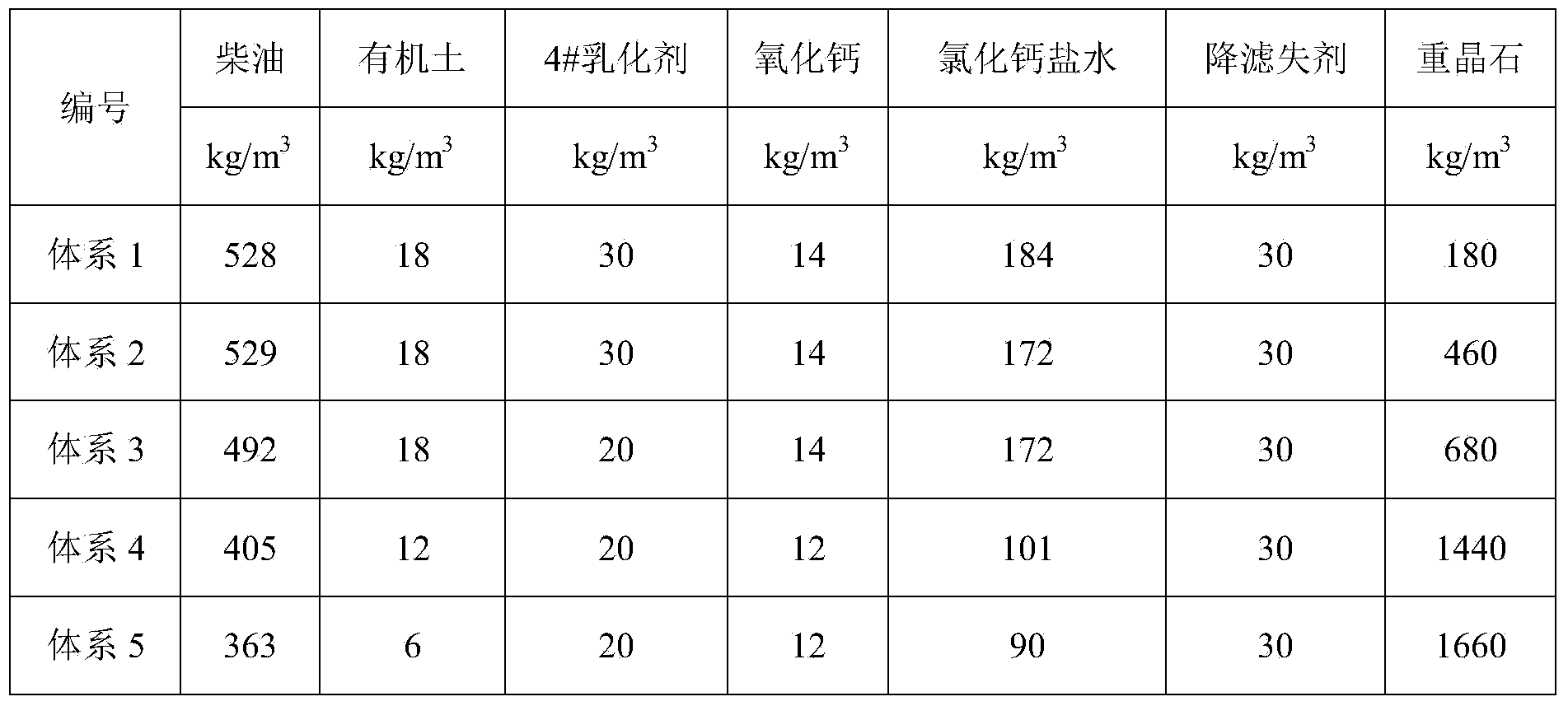

[0029] The emulsifier A, emulsifier B, and emulsifier C obtained abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com