Environmentally-friendly dyeing liquid for uniformly dyeing ultrafine fiber leather

A technology of ultra-fine fiber and dyeing solution, which is applied in the field of dyes, can solve the problem of deviation of dyeing effect from the original idea, and achieve the effect of improving color fastness, low production cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

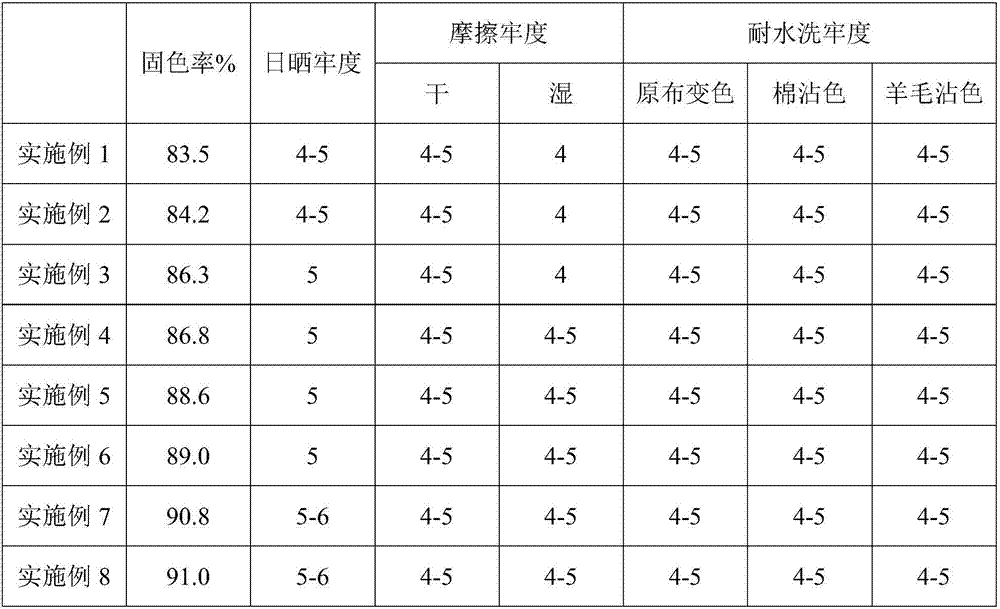

Examples

Embodiment 1

[0019] In the embodiment of the present invention, the environmentally friendly dyeing liquid used for uniform dyeing of microfiber leather includes the following raw materials: 5 kg of dye, 10 kg of dimethylformamide, 3 kg of linolenic acid, 10 kg of butyl acetate, 1 kg of polyvinylpyrrolidone, and styrene 5kg, sodium lignosulfonate 1kg, terpene resin 5kg, sodium hexametaphosphate 0.5kg, linear low density polyethylene 3kg, tannin extract 1kg, hydrogenated rosin 1kg, sodium alkylarylsulfonate 1kg, ceramic micropowder 1kg, sucrose 1kg of ester, 0.5kg of polyacrylamide, 200kg of water. Mix the dye with water, stir and dissolve to form an aqueous dye solution. Add dimethylformamide, linolenic acid, butyl acetate, polyvinylpyrrolidone, styrene, sodium lignosulfonate, terpene resin, sodium hexametaphosphate, linear low-density polyethylene, tannin extract, hydrogenated Rosin, sodium alkylaryl sulfonate, ceramic micropowder, sucrose ester, and polyacrylamide were stirred for 10 mi...

Embodiment 2

[0021] In the embodiment of the present invention, the environmentally friendly dyeing solution used for uniform dyeing of ultrafine fiber leather includes the following raw materials: 110 kg of dye, 120 kg of dimethylformamide, 30 kg of linolenic acid, 50 kg of butyl acetate, 15 kg of polyvinylpyrrolidone, styrene 35kg, sodium lignosulfonate 110kg, terpene resin 30kg, sodium hexametaphosphate 15kg, linear low density polyethylene 25kg, tannin extract 120kg, hydrogenated rosin 22kg, sodium alkylarylsulfonate 15kg, ceramic micropowder 20kg, sucrose ester 25kg, polyacrylamide 45kg, water 600kg.

[0022] Mix the dye with water, stir and dissolve to form an aqueous dye solution. Add dimethylformamide, linolenic acid, butyl acetate, polyvinylpyrrolidone, styrene, sodium lignosulfonate, terpene resin, sodium hexametaphosphate, linear low-density polyethylene, tannin extract, hydrogenated Rosin, sodium alkylaryl sulfonate, ceramic micropowder, sucrose ester, and polyacrylamide were ...

Embodiment 3

[0024] In the embodiment of the present invention, the environmentally friendly dyeing solution used for uniform dyeing of microfiber leather includes the following raw materials: 8 kg of dye, 15 kg of dimethylformamide, 5 kg of linolenic acid, 15 kg of butyl acetate, 1 kg of polyvinylpyrrolidone, and styrene 8kg, sodium lignosulfonate 3kg, terpene resin 8kg, sodium hexametaphosphate 0.8kg, linear low density polyethylene 4kg, tannin extract 5kg, hydrogenated rosin 2kg, sodium alkylarylsulfonate 1kg, ceramic micropowder 1kg, sucrose 2kg of ester, 0.8kg of polyacrylamide, and 220kg of water.

[0025] Mix the dye with water, stir and dissolve to form an aqueous dye solution. Add dimethylformamide, linolenic acid, butyl acetate, polyvinylpyrrolidone, styrene, sodium lignosulfonate, terpene resin, sodium hexametaphosphate, linear low-density polyethylene, tannin extract, hydrogenated Rosin, sodium alkylaryl sulfonate, ceramic micropowder, sucrose ester, and polyacrylamide were st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com