Corn thresher

A thresher and corn technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of reduced threshing efficiency, low cleaning rate, easy damage of grains, etc., to achieve convenient use and adjustment, high cleaning rate , wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

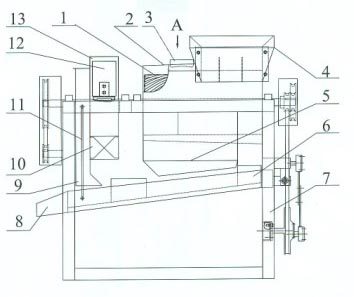

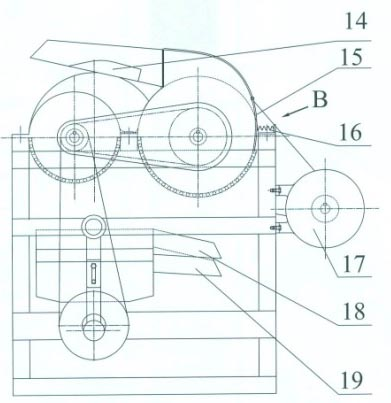

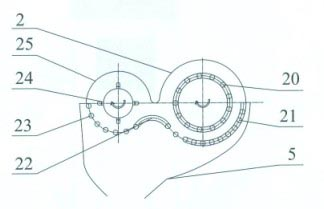

[0023] See Figure 1-10 , the specific structure of the present invention is as follows: the front threshing cylinder 1 and the rear threshing cylinder 24 are assembled side by side through the rotating shaft 26 on the frame 7; 20. The threshing ribs 20 are threaded steel rods with a diameter of 10-12mm, and the distance between the ribs is 30mm; the spiral threshing ribs 20 form an included angle of 20-30° with the cylinder generatrix of the drum. An adjusting screw sleeve 27 is provided between the inner side of the front threshing cylinder 1 and the rotating shaft 26 to facilitate the disassembly and replacement of the front threshing cylinder 1, so as to achieve the purpose of adjusting the gap between different diameter cylinders and the lower concave plate, and realize the requirements for threshing different corns. A spiral grid concave plate 21 is installed under the front threshing cylinder 1; a conical machine cover 2 is installed above the front threshing cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com