ultrasonic cleaner

An ultrasonic cleaning machine technology, applied in the field of ultrasonic cleaning, can solve the problems of low work efficiency and high labor intensity, and achieve the effects of short cleaning time, high electro-acoustic efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

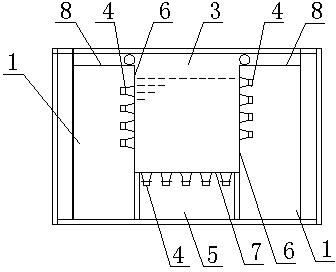

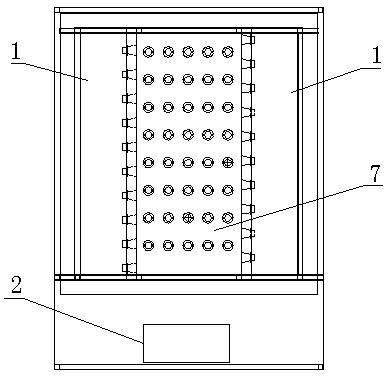

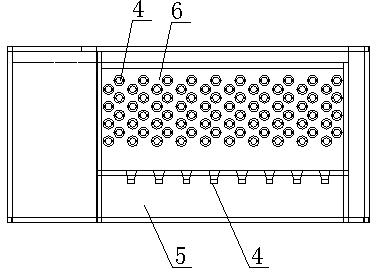

[0014] see Figure 1 to Figure 3 , an ultrasonic cleaning machine, which includes a cleaning pool 3, vibrator chambers 1 are respectively arranged on both sides of the cleaning pool 3, the cleaning pool 3 and the vibrator chamber 1 are isolated by side partitions 6, and several vibrators 4 are arranged on the outer wall of the side partitions 6, The bottom vibrator chamber 5 is arranged under the bottom partition 7 of the cleaning tank 3 , and several vibrators 4 are arranged on the bottom surface of the bottom partition 7 ; all vibrators 4 are connected to the ultrasonic generator 2 . The tops of the two vibrator chambers 1 are respectively provided with cover plates 8 . Vibrator 4 is also called an ultrasonic transducer.

[0015] The working principle of the present invention: fill the cleaning tank 3 with cleaning liquid, put a number of electrolytic cathode plates into the cleaning tank 3 stably by a crane, put the electrolytic negative plates upright into the cleaning ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com