Thin jute fiber non-woven fabric for packaging and production method for thin jute fiber non-woven fabric

A technology of jute fiber and manufacturing method, applied in textiles, papermaking, non-woven fabrics and other directions, can solve the problems of non-degradation and low strength of hemp fiber non-woven fabrics, and achieves improved softness, green production process and environmental protection. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

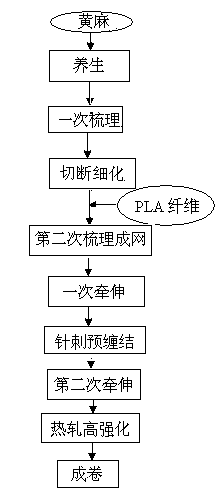

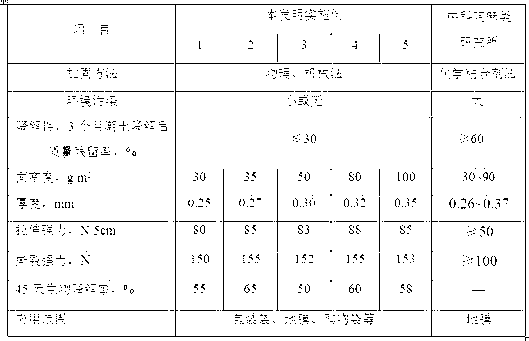

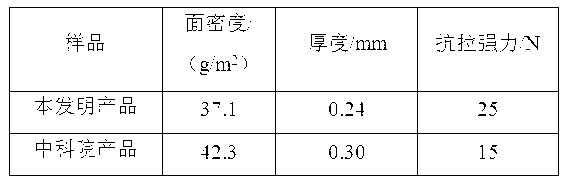

[0039] A kind of thin jute fiber non-woven fabric for packing, its component is calculated by weight percentage: 65% of jute fiber, 35% of PLA fiber. The thin jute fiber non-woven fabric for packaging is made through the following steps, and the process flow chart is shown in figure 1 :

[0040](1) Carry out health-preserving treatment of jute fiber;

[0041] (2) Carding the jute fibers after the health-preserving treatment, and then cutting and refining, so that the fineness of the jute fibers is reduced by 50%, and become ultra-fine jute fibers with a diameter of 20 μm;

[0042] (3) The fibers mixed with ultra-fine jute fibers and PLA fibers are carded for the second time and drafted for the first time to form a web;

[0043] (4) The mixed fibers that have been cross-formed by first drawing are pre-entangled by needle punching and then drawn for the second time, so that the surface density of single-fiber PLA fibers and ultra-fine jute fibers is 25g / m 2 fiber;

[0044] (...

Embodiment 2

[0046] A kind of thin jute fiber non-woven fabric for packaging, its components are calculated by weight percentage: 75% of jute fiber, 25% of PLA fiber. The thin jute fiber non-woven fabric for packaging is made through the following steps:

[0047] (1) Carry out health-preserving treatment of jute fiber;

[0048] (2) Carding the jute fibers after the health-preserving treatment, and then cutting and refining, so that the fineness of the jute fibers is reduced by 50%, and become ultra-fine jute fibers with a diameter of 45 μm;

[0049] (3) The fibers mixed with ultra-fine jute fibers and PLA fibers are carded for the second time and drafted for the first time to form a web;

[0050] (4) The mixed fibers after one-time drafting and cross-forming treatment are needled three times, and the needle punching density is 195 punches / cm 2 , the needling depth is 10mm, and the second drawing is carried out after pre-entanglement, so that the surface density of single-fiber PLA fibers...

Embodiment 3

[0053] A kind of thin jute fiber non-woven fabric for packaging, its components are calculated by weight percentage: jute fiber 68%, PLA fiber 32%. The thin jute fiber non-woven fabric for packaging is made through the following steps:

[0054] (1) Carry out health-preserving treatment of jute fiber;

[0055] (2) Carding the jute fibers after the health-preserving treatment, and then cutting and refining, so that the fineness of the jute fibers is reduced by 50%, and become ultra-fine jute fibers with a diameter of 30 μm;

[0056] (3) The fibers mixed with ultra-fine jute fibers and PLA fibers are carded for the second time and drafted for the first time to form a web;

[0057] (4) The mixed fibers after one-time drafting and cross-forming treatment are needled three times, and the needle punching density is 210 punches / cm 2 , the needling depth is 120mm, and the second drawing is carried out after pre-entanglement, so that the single-fiber PLA fiber and ultra-fine jute fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Needling density | aaaaa | aaaaa |

| Acupuncture depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com