Patents

Literature

222 results about "Pinnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pinnation (also called pennation) is the arrangement of feather-like or multi-divided features arising from both sides of a common axis. Pinnation occurs in biological morphology, in crystals, such as some forms of ice or metal crystals, and in patterns of erosion or stream beds.

Fire retardant cotton nonwoven fabrics and manufacture method thereof

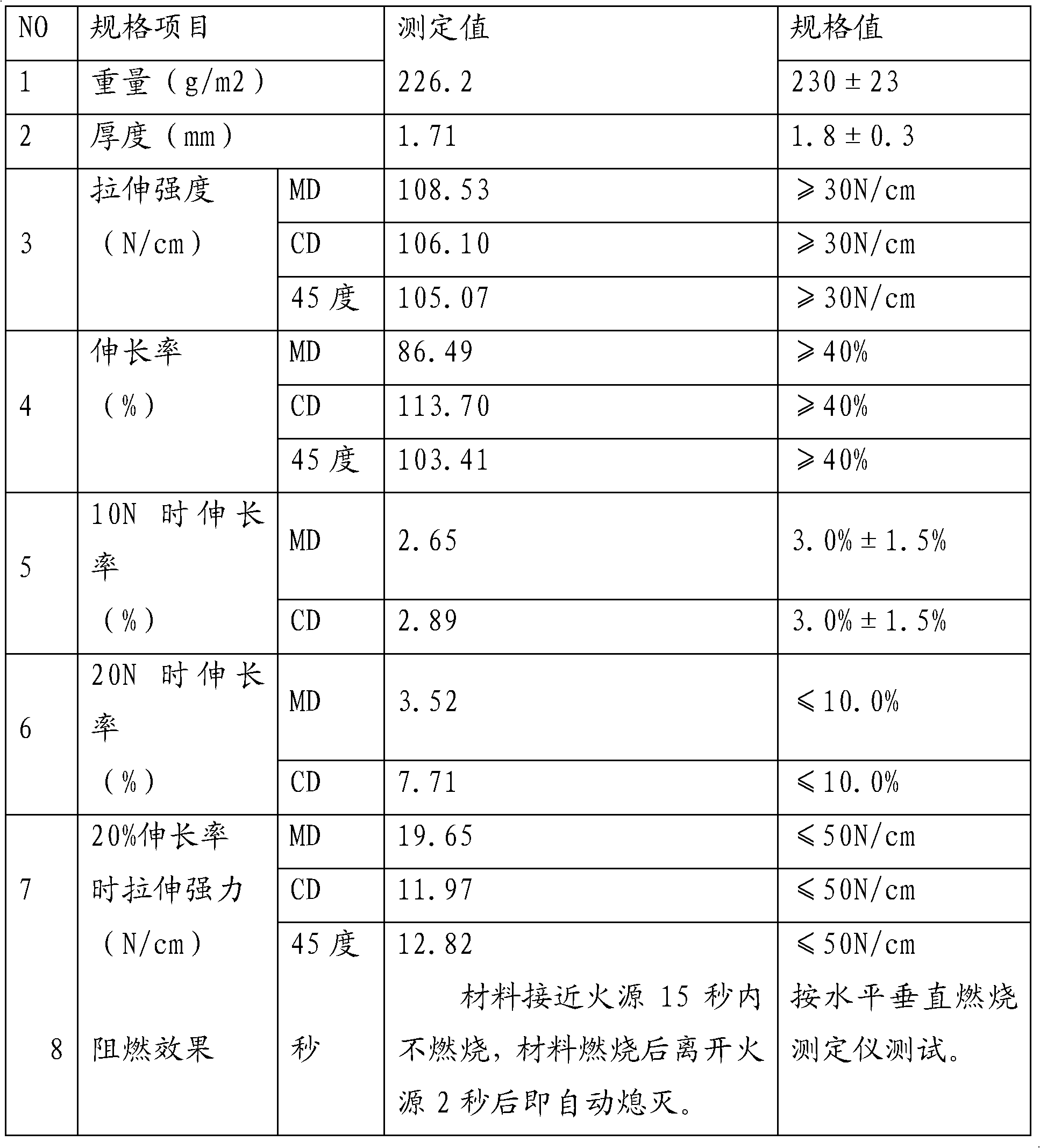

InactiveCN101307528AImprove flame retardant performanceGood anti-melting effectHeating/cooling textile fabricsNon-woven fabricsCardingPolymer science

The invention discloses an flame retardant non-woven cotton fabric, comprising anti-fcell flame retardant fiber and washing / washing composite hot melting short fiber, wherein, the weight percentage of the anti-fcell flame retardant fiber is between 70 and 90 percent, the balance is the washing / washing composite hot melting short fiber; the two fibers are stuck into an integrated whole by the hot wind heating and / or are penetrated together by prickling fibers to combine into the non-woven fabric. The method for producing the non-woven cotton fabric comprises the processes of mixing, opening, carding, mesh placing, moulding processing, etc. The moulding processing method has the needle point method and the through-air method. The flame retardant non-woven cotton fabric adopts the prescription of mainly taking the anti-fcell flame retardant fiber and solves the problems of the flammability of the terylene, dropping of the fusion and the flammability of the viscose. The washing / washing composite hot melting short fiber is added to increase the caking coefficient so that the fibers are conglutinated evenly. The unique processing flow ensures that the inflaming retarding non-woven cotton fabric has high tension intensity and anti-breakage intensity as well as certain elasticity and bulkiness.

Owner:DONGGUAN LIANYING NONWOVEN TECH

Manufacturing method of bast fiber nonwoven fabric

InactiveCN101324012AEasy to manufactureAvoid breakingNon-woven fabricsAdhesivesNonwoven fabricMaterials science

The invention discloses a production method of a fibrilia non-woven fabric and comprises following steps: (1) opening and mixing: the fibrilia is opened once, bonding fiber and other fibers are opened for two or more times, and the opened fibrilia, bonding fiber and other fibers are mixed; (2) the mixed fibers are processed into a meshwork; (3) prickling shaping: the fiber meshwork that is obtained from step (2) is prickled by a needle machine; (4) hot rolling shaping: the fiber meshwork that is obtained after the prickling is transmitted onto a roll squeezer to be rolled, and the hot rolling shaping is implemented. The production method of the fibrilia non-woven fabric is simple, and the opening times of the fibrilia is limited, thus avoiding fibrilia break that is caused by a plurality of opening times, and consequently ensuring the length of the fibers and being convenient for the production of the non-woven fabric; simultaneously the opening of other fibers excluding the fibrilia is implemented for two or more times, thus ensuring full opening of the fibers and being convenient for the production of the non-woven fabric.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

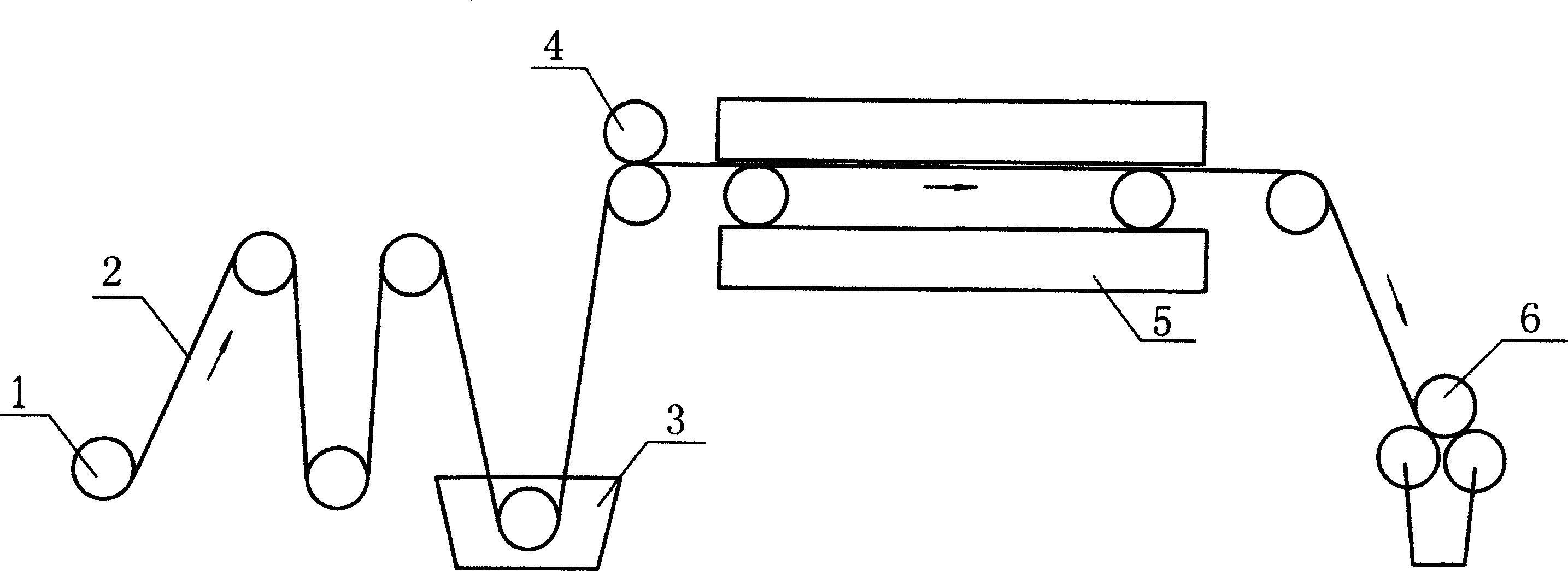

Needled felt surface processing agent and impregnation technology thereof

InactiveCN1827905AImprove corrosion resistanceImprove self-cleaning abilityFibre treatmentEmulsionFilm-forming agent

The invention relates the needled felt surface processing agent and impregnation technology. The surface processing agent comprises film-forming agent, fabric finishing agent and coupling agent. The formulation is following: 1 4-15% fluoroplymer emulsion; 2 1-20% macromolecular ester polyaromatics; 3 1-8% silicon oil emulsion; 4 0.1-1% coupling agent; 5 0.3-3% nano materials; 6 water. The technology comprises the following steps: unfolding the needled felt, through impregnating bath, squeezing with pair roller extruding machine, drying the wet felt, wrapping the needled felt, and getting the product. The technology improves the physical chemical properties and durability of needled felt filter material.

Owner:SINOMA SCI & TECH

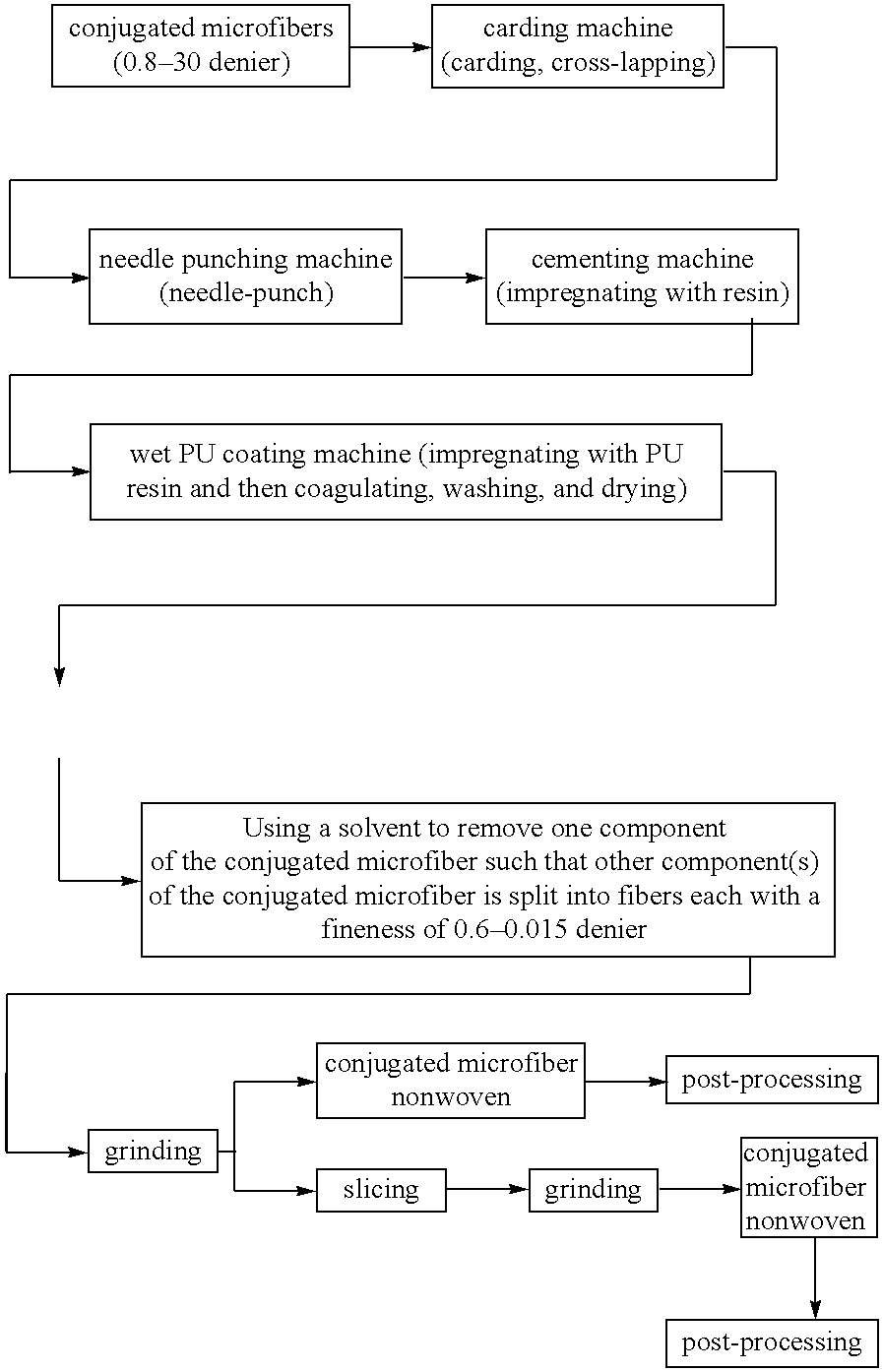

Scratch resistant processing method of non-figured island ultrafine fiber napped leather

ActiveCN101591860AChange the distribution status of the islandHigh process flexibilityFabric breaking/softeningSolvent-treatmentLow-density polyethylenePolyamide

The invention relates to a scratch resistant processing method of non-figured island ultrafine fiber napped leather, which comprises the following steps: taking PA6 as an island; taking PE with low density as the sea; adding a small amount of ionic polymer; and spinning an ultrafine fiber by a single-screw blending method. The ultrafine fiber is needled into non-woven fabrics, impregnated with PU resin, reduces toluene contents, and is expanded for drying, sliced, ground, and the like to manufacture ultrafine fiber napped leather. The islands of the ultrafine fiber are partially crosslinked due to the function of ionic compound in a production flow so as to prevent the fiber in the napped leather from falling when the napped leather is used as a material to be made into products of gloves, shoes, clothing, bags, suitcases, and the like, thereby greatly improving the scratch resistance of the napped leather.

Owner:HUAFON MICROFIBER SHANGHAI

Production of needled filtering felt of polytef fibre

ActiveCN1982523AHigh temperature resistantGood low frictionFiltration separationNon-woven fabricsAntistatic agentFiltration

Production technology of a kind of teflon fiber needled filter carpet, its main steps include : 1) use antistatic agent to eliminate the static teflon fiber, fully-open, then balanced place into stainless steel drums and make stainless steel drums fully grounding discharge; 2) the carding machine and roll machine fully grounding discharge; 3) the fibers are fed to carding machine, then the regular fiber are laid through network machine, and form hair nets; 4) lay teflon basal cloth bottom of single layer hair net, then basal cloth and single layer hair nets together introduce into needle machine forming carpet; 5) use forming machines to form the carpet by heat, and then deal it with singeing. With the process, can produce 100% teflon fiber needled filter carpet, such acupuncture filter carpet has good chemical properties, good filtration efficiency, good cleaning performance and longer service life.

Owner:厦门佰瑞福环保科技有限公司

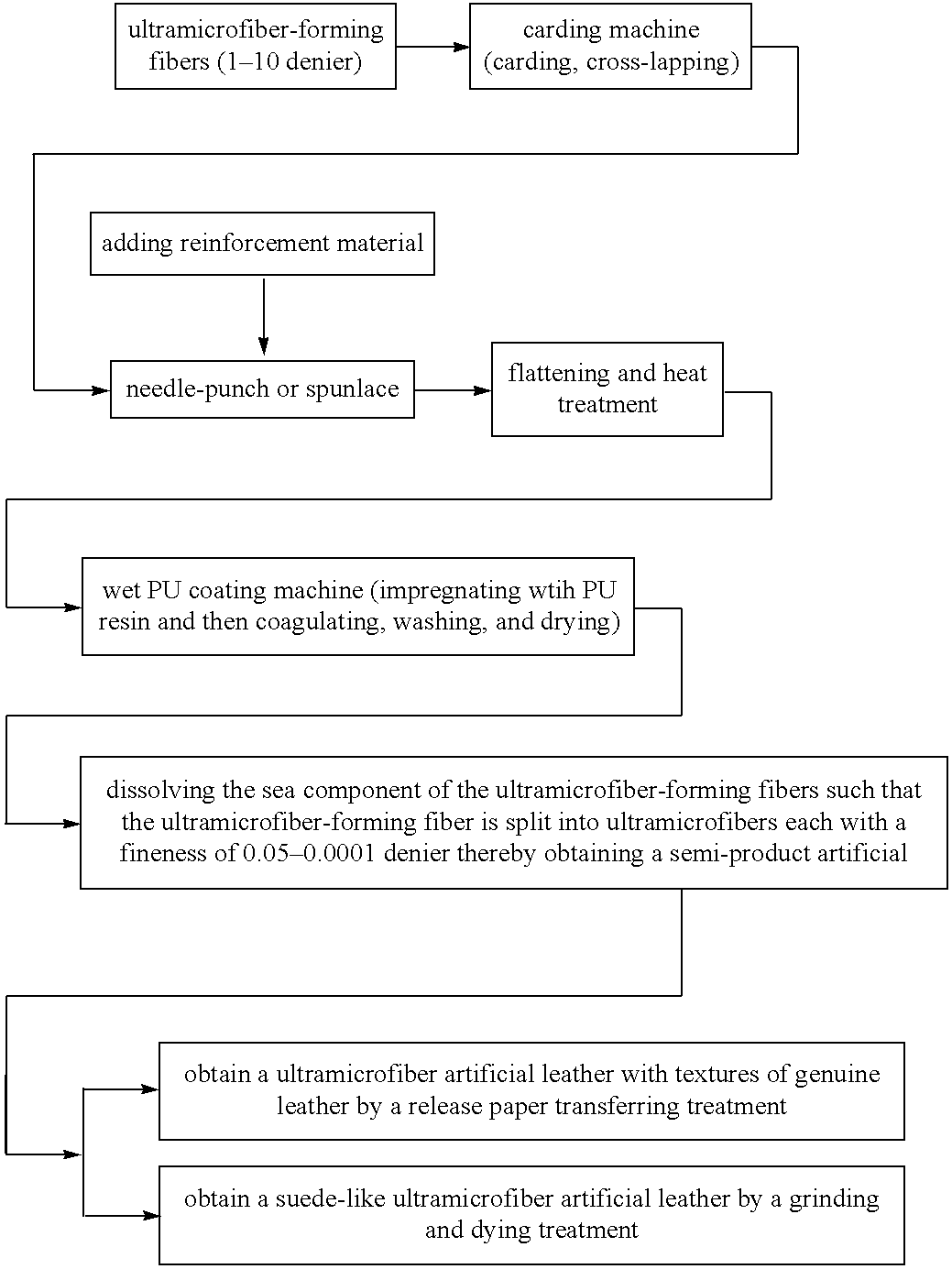

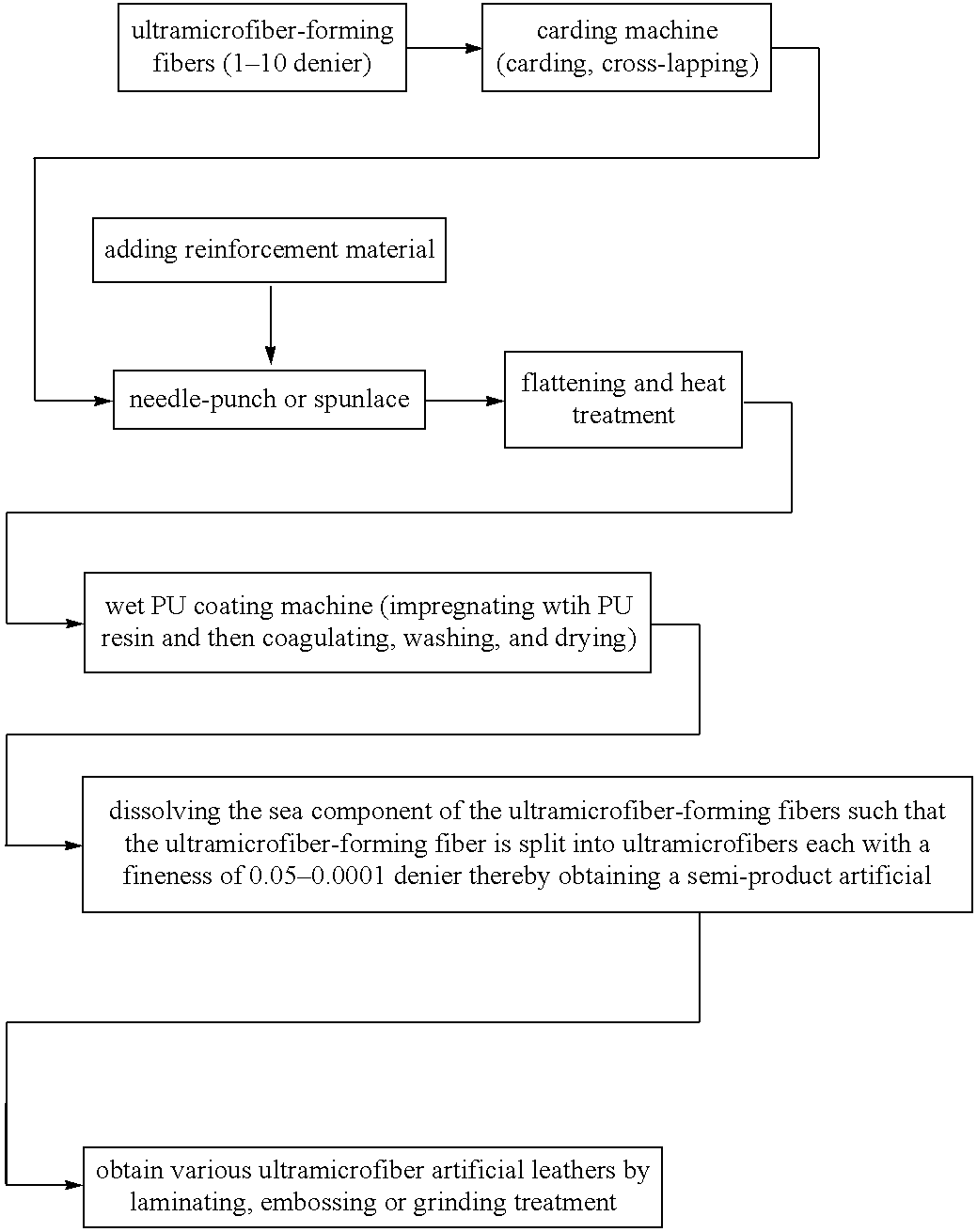

Artificial leather composite reinforced with ultramicrofiber nonwoven fabric

InactiveUS7132024B2Reduce manufacturing stepsGood suppression characteristicsSynthetic resin layered productsWoven fabricsElastomerPolyester

A method for manufacturing an artificial leather comprises the following steps. First, ultramicrofiber-forming fibers having an islands-in-sea type cross-sectional configuration are formed by blend spinning or conjugate spinning. Secondly, a porous reinforcement sheet of low compactness is formed from polyester, polyurethane or polyolefin by spunbonding, meltblowing or calendering. Next, the ultramicrofibers are entangled with the reinforcement sheet by needle punching or spunlace to form the complex reinforced ultramicrofiber nonwoven fabric. The nonwoven is impregnated or coated with an elastomer resin composition, and then subjected to a coagulating process, a washing process, a drying process and a removing process to produce a semi-product leather. Finally, the semi-product leather is then processed to produce the artificial leather.

Owner:SAN FANG CHEM IND

Method for manufacturing needle-punched carbon fiber pseudo-three-dimensional preform

InactiveCN101575766AImprove wear resistanceExtended service lifeNeedling machinesCarbon compositesCarbon fibers

The invention relates to a method for manufacturing a needle-punched carbon fiber pseudo-three-dimensional preform, which comprises the following steps: adopting alternating laminations of continuous carbon fibers and short carbon fiber mesh carcasses, wherein the laminations of the continuous carbon fibers are paved alternately with included angles between 0 and 30 degrees; and introducing longitudinal fortifying fibers through a needle-punching process in the axial direction of the short carbon fiber mesh carcasses and the continuous carbon fiber laminations, and controlling the needling density to between 36 to 44 needles / cm so as to manufacture a full carbon fiber pseudo-three-dimensional structural preform with the volume density of between 0.55 and 0.82g / cm. The preform manufactured by the method has the most important characteristics of high volume content of the carbon fibers, evener continuous carbon fiber laminations, high needling density, high mechanical property of a manufactured carbon / carbon composite material and good wear resistance, and is applicable to manufacturing aircraft carbon brake disc materials with high torque characteristics.

Owner:XIAN CHAOMA SCI TECH

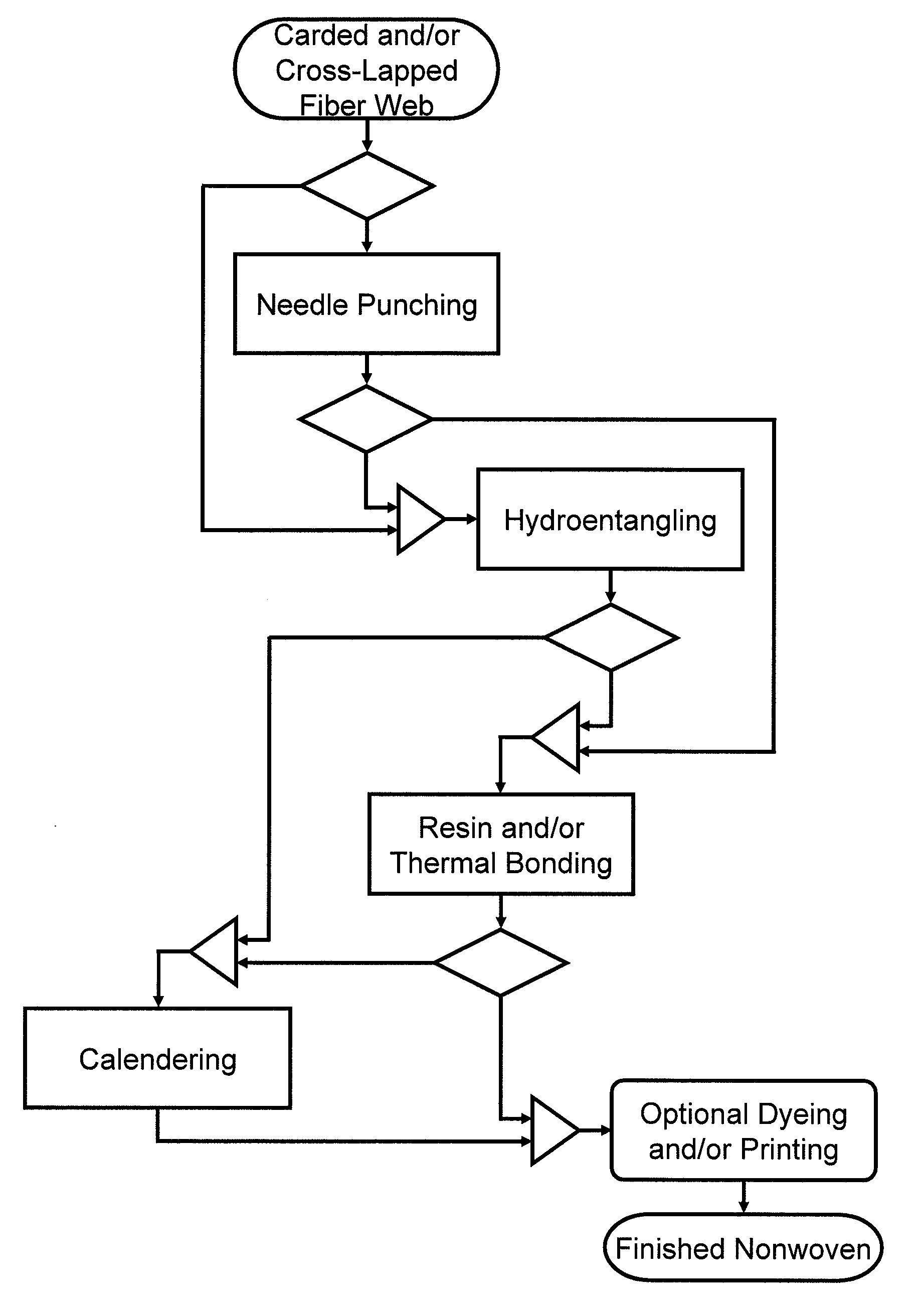

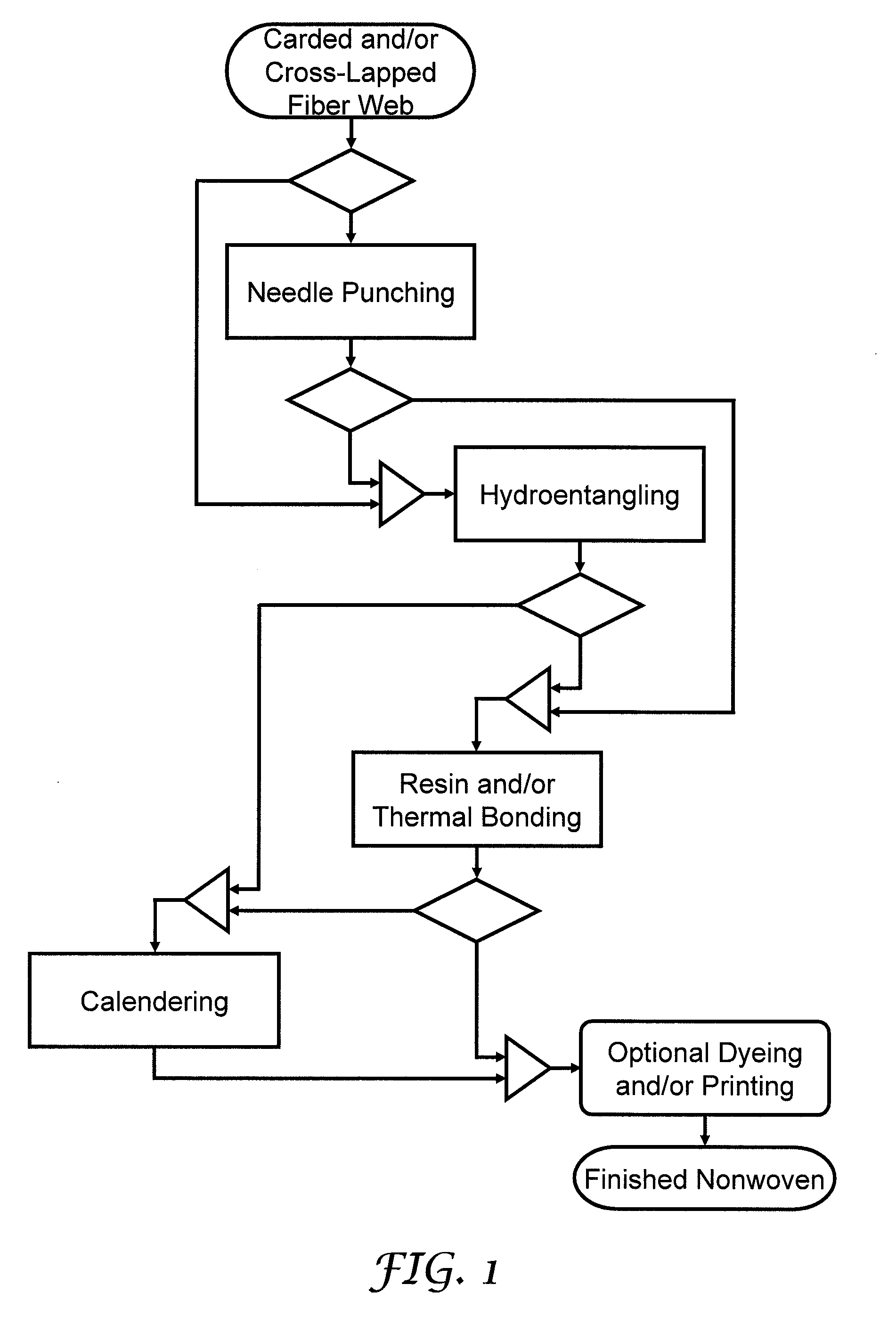

Staple fiber durable nonwoven fabrics

ActiveUS20090258559A1Improve strength and durabilityLayered productsWoven fabricsPunchingEngineering

The invention provides durable nonwoven fabrics comprising staple fibers. Methods of preparing durable nonwoven fabrics based on staple fibers are also provided. The methods can include the steps of at least one of needle punching and hydroentangling. The durable nonwoven fabric can be subjected to additional bonding techniques, such as resin bonding and / or thermal bonding. The durable nonwoven fabrics of the invention provide improved durability over conventional nonwoven fabrics. Further advantages of the inventive nonwoven fabrics include maintaining the smooth surface qualities of the fabric and desirable feel of the fabric even with the enhanced durability. The inventive nonwoven fabrics can also be subjected to additional post-processing techniques that conventional nonwoven fabrics would otherwise be unable to withstand. Further, inks and / or dyes can more readily become adhered to the smooth nature of the surfaces of the inventive durable nonwoven fabrics.

Owner:NORTH CAROLINA STATE UNIV

Antistatic, conductive and electromagnetic shielding textile and preparation method thereof

InactiveCN101580998AImprove bonding fastnessFeel goodWeft knittingFibre treatmentTinningTextile fiber

The invention relates to an antistatic, conductive and electromagnetic shielding textile and a preparation method thereof, being characterized in that fiber filament is firstly processed by electroless plating copper in a way of continuous proceeding and then processed by electrolytic tinning to prepare conductive filament; then, the conductive filament is cut into conductive short fiber which is processed by pure spinning or blend spinning with other common textile fibers to be made into yarn, and the antistatic, conductive and electromagnetic shielding textile can be prepared by fabric manufacture as well as dyeing and finishing; or the conductive short fiber is blended with other common textile fibers and then processed into non-weaving cloth by pinprick or spunlace. The textile prepared by the invention has beautiful appearance and soft feel, and is safe to the skin.

Owner:ZHEJIANG SCI-TECH UNIV

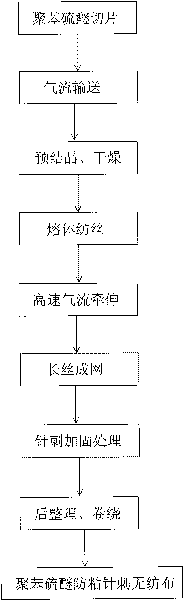

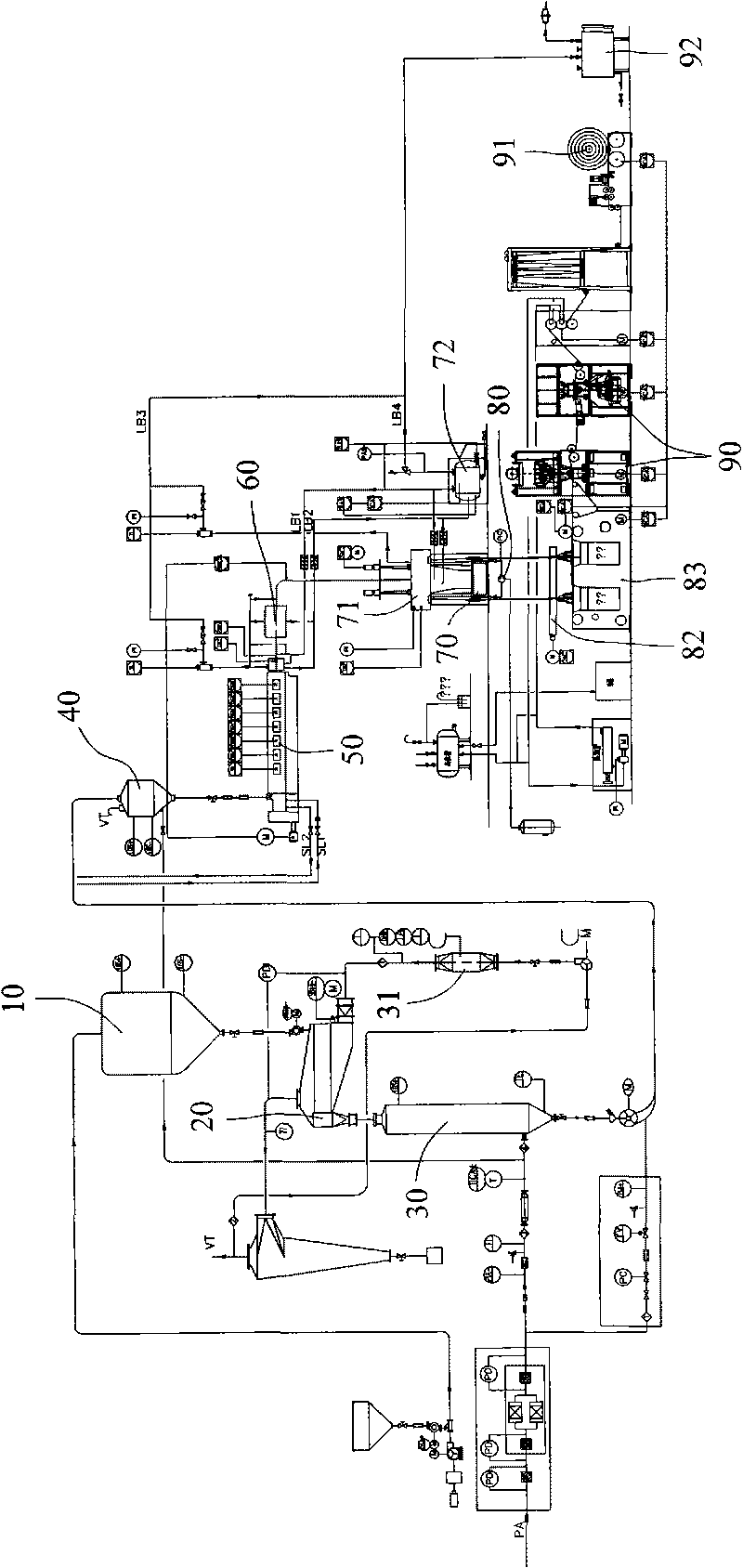

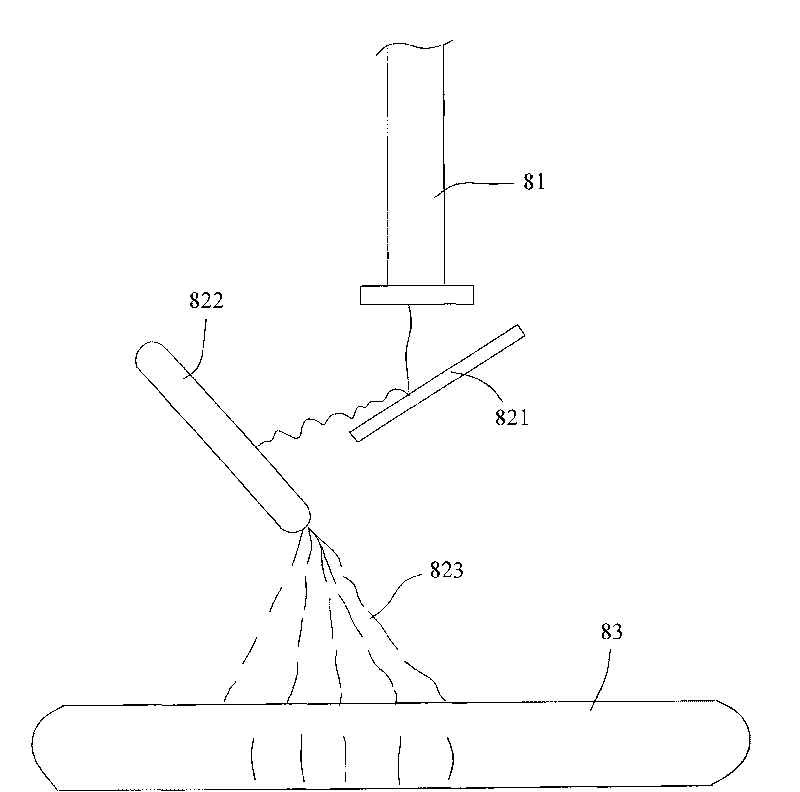

Method for preparing polyphenylene sulfide spun-bonded needle punched non-woven fabrics and device thereof

ActiveCN101760903ASpeed up the processLabor savingArtificial thread manufacturing machinesMelt spinning methodsPunchingSulfide

The invention relates to a method for preparing polyphenylene sulfide spun-bonded needle punched non-woven fabrics, comprising the steps: slicing of polyphenylene sulfide-pneumatic conveying-precrystallization-drying- melt spinning-air drawing-filament web-forming-needle-punching reinforcement-after finishing-winding, resulting in the polyphenylene sulfide spun-bonded needle punched non-woven fabrics. The invention further discloses a device for the implementation of the method for preparing polyphenylene sulfide spun-bonded needle punched non-woven fabrics. Compared with short fiber needle-punched method for the production of polyphenylene sulfide needle punched non-woven fabrics, the method for preparing polyphenylene sulfide needle punched non-woven fabrics by using spun-bonded filament needle punched method has the advantages of short technological procedures, small number of apparatuses, less required labor force, high production efficiency and large yield.

Owner:FOSHAN S L P SPECIAL MATERIALS

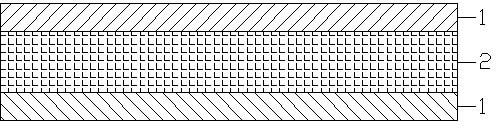

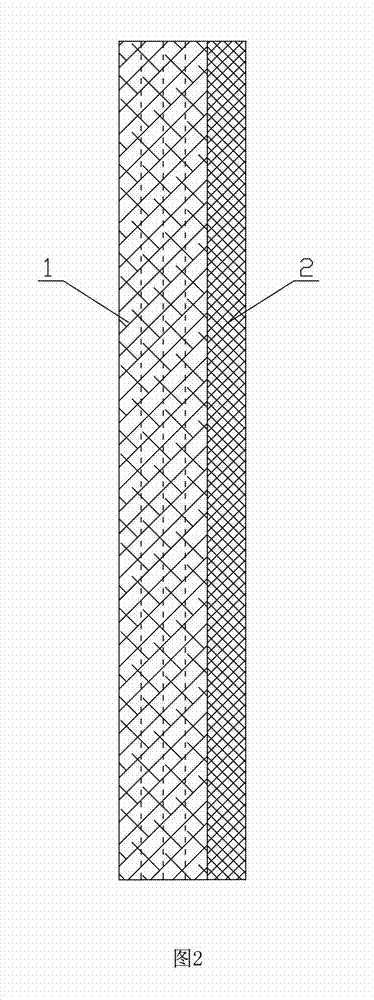

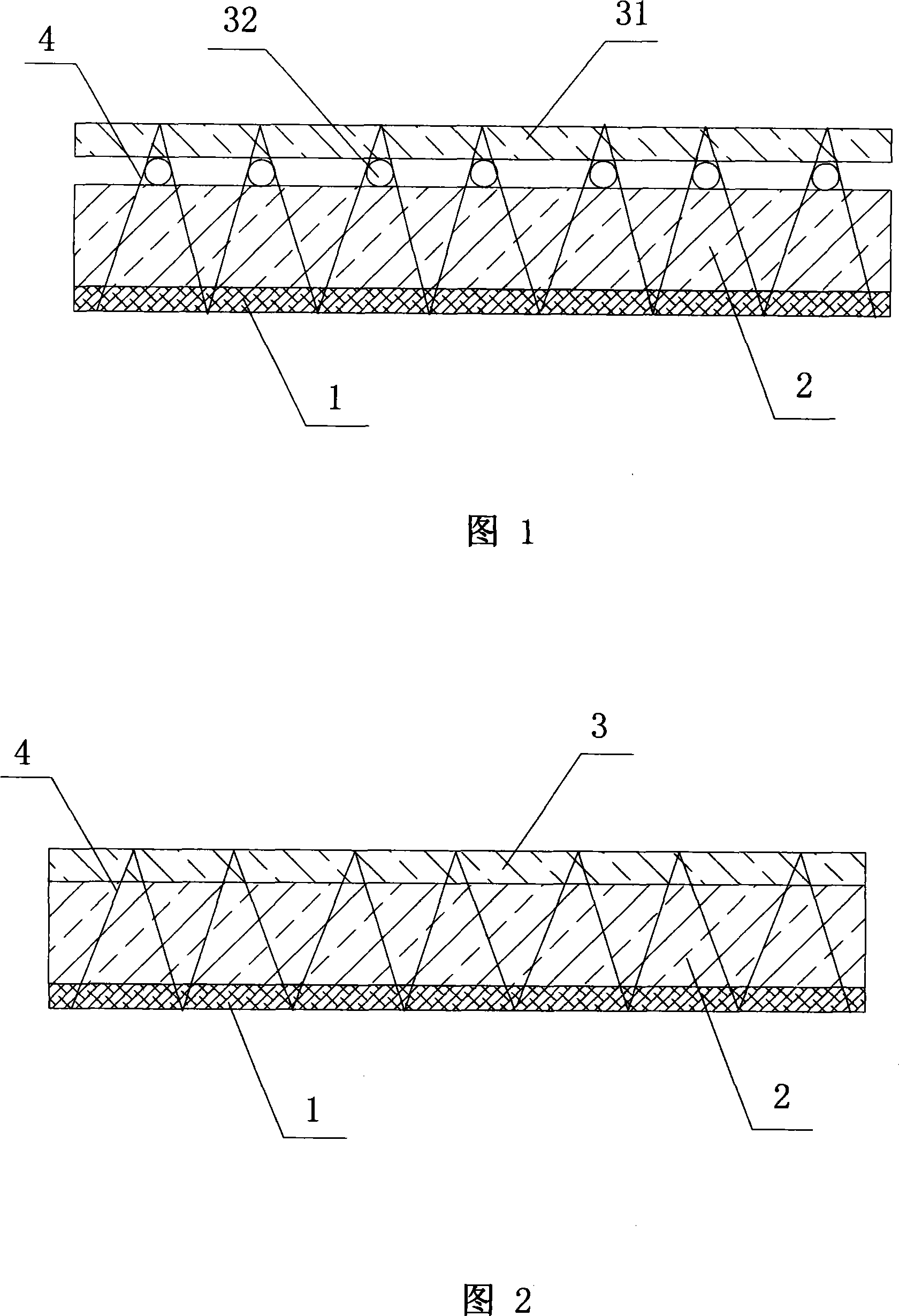

Lightweight and environment-friendly type fibrilia composite plate and preparation method thereof

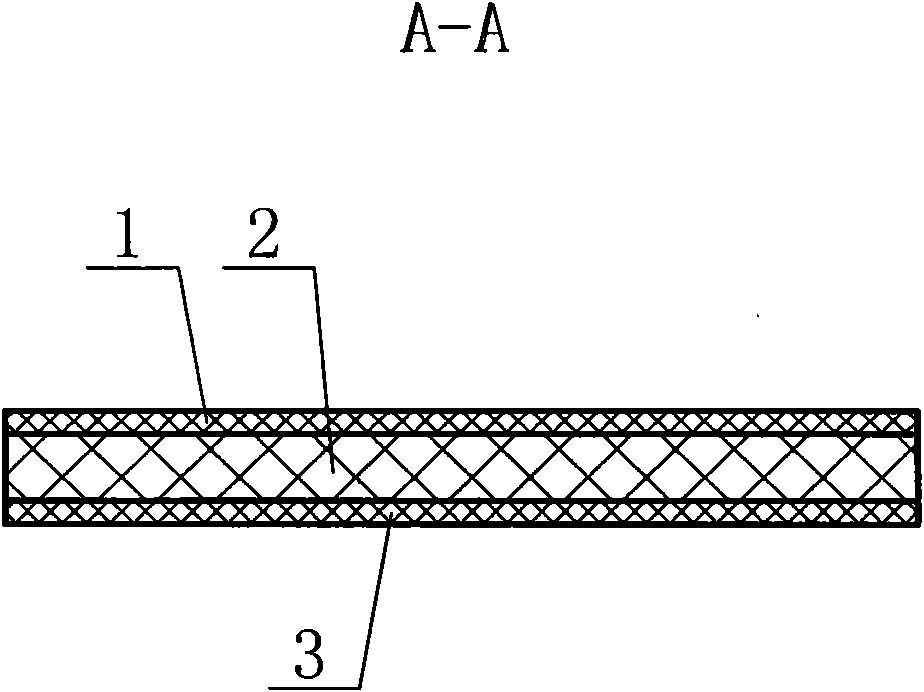

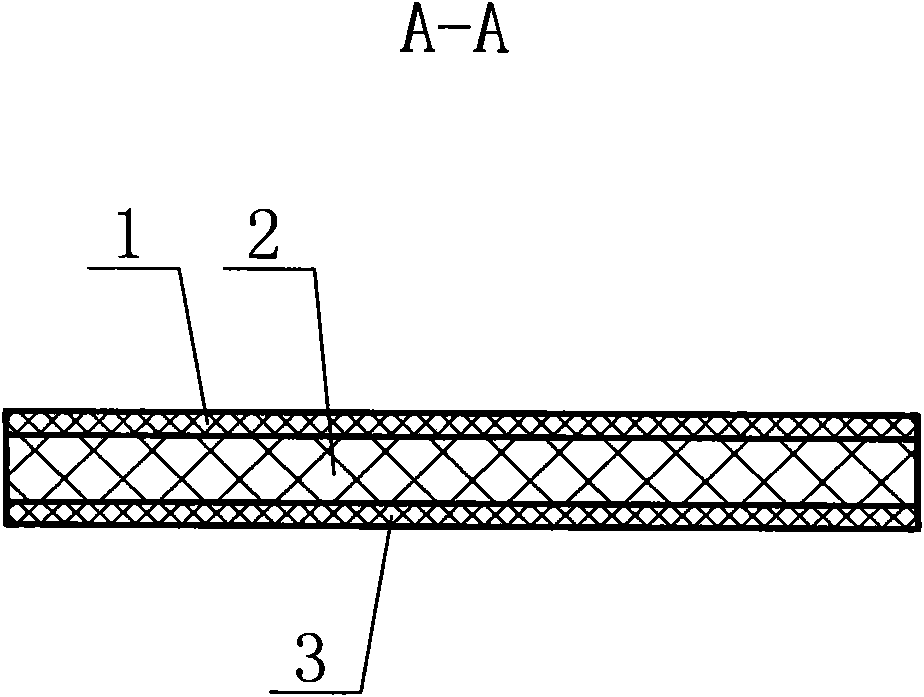

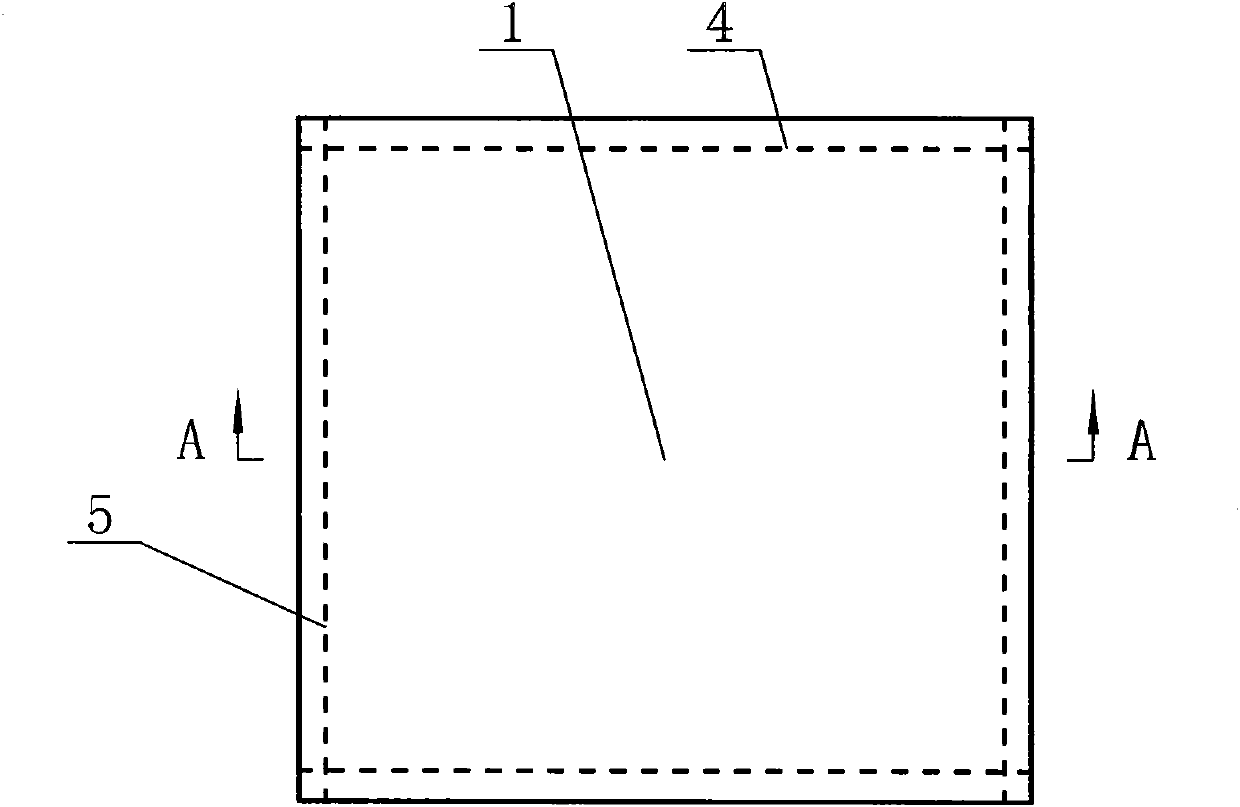

ActiveCN102602067APlay a skeleton roleHigh strengthSynthetic resin layered productsLaminationComposite plateMoisture regain

The invention relates to a lightweight and environment-friendly type fibrilia composite plate and a preparation method thereof, belonging to the technical field of interior ornaments for automobile decoration. The composite plate comprises PE (polyethylene) film layers (1) and a fibrilia mat layer (2), wherein the fibrilia mat layer (2) is an intermediate layer, and the PE film layers (1) are compounded on the upper surface and lower surface of the fibrilia mat layer (2); and the fibrilia mat layer (2) is a needle-punched fibrilia mat, comprises 55-65% by weight of fibrilia and 35-45% by weight of PP (polypropylene) fiber, and is formed by mixing, forming a net and performing needle-punching. The method comprises the following steps of: (1) fibrilia processing: soaking the harvested fibrilia raw material in a hydrogen peroxide solution for 20-25 days, then washing with water, and further sequentially performing peeling, airing, opening, coiling and cutting off so as to produce a fibrilia crude product; and (2) performing rinsing, drying and fine opening on the fibrilia crude product for later use. The prepared composite plate has the advantages of low density, high strength, good stretch-proof effect, low probability of moisture regain and mildew, no toxicity and environmental protection.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

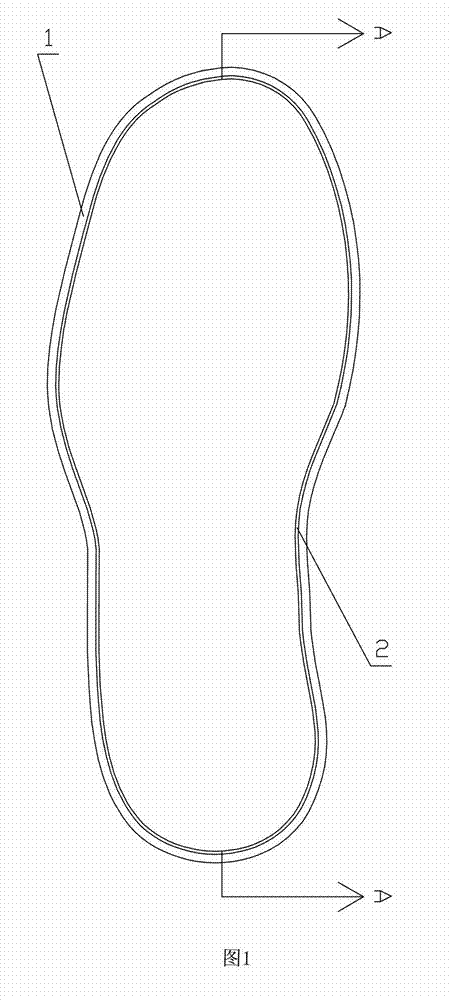

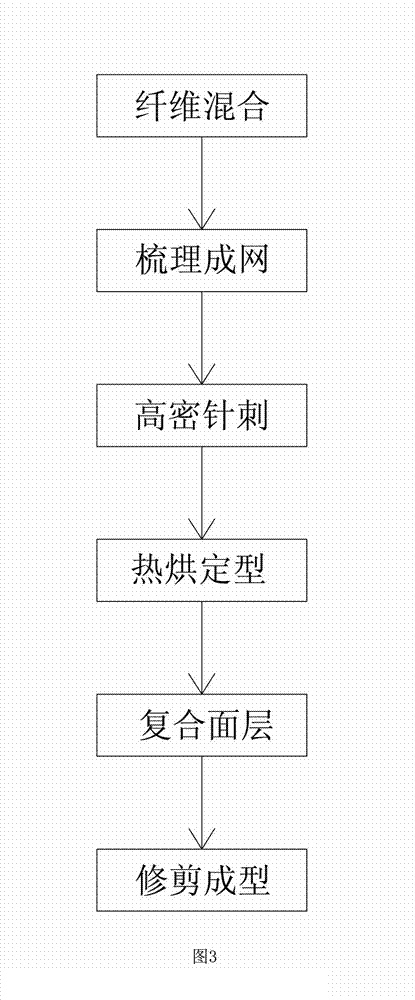

Environmentally-friendly multifunctional insole and production process thereof

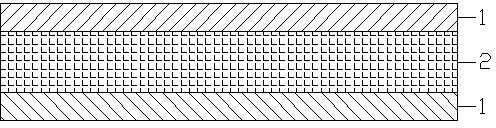

InactiveCN102326921BWith antibacterial and deodorant functionHas the function of promoting blood circulationLayered productsInsolesCompound aSurface layer

The invention discloses an environmentally-friendly multifunctional insole, which has high elasticity and high sweat absorbing, ventilating, environment protecting, sterilizing, deodorizing and blood circulation invigorating performance and comprises a surface layer and a base layer, wherein the base layer is a high-density needled non-woven fabric made from bamboo charcoal fiber and far infraredterylene in the mass ratio 1:1. The production process of the insole comprises the following steps of: weighing a preset amount of bamboo charcoal fiber and far infrared terylene in the weight part ratio 1:1; fully loosening and mixing the bamboo charcoal fiber and the far infrared terylene; carding into a fiber netlike structural body; treating the netlike structural body with a high-density needling process to form a layered object with regular intervals; conveying the layered object into a baking oven for baking and shaping; compounding a baked and shaped product with the surface layer required by a customer; and trimming and molding according to the requirement on the size of the insole. The production process of the multifunctional insole is simple and practical; and the multifunctional insole has the characteristics of durability, washing resistance and non-deformability.

Owner:JINJIANG CHENHUI SHOES MATERIAL TRADE

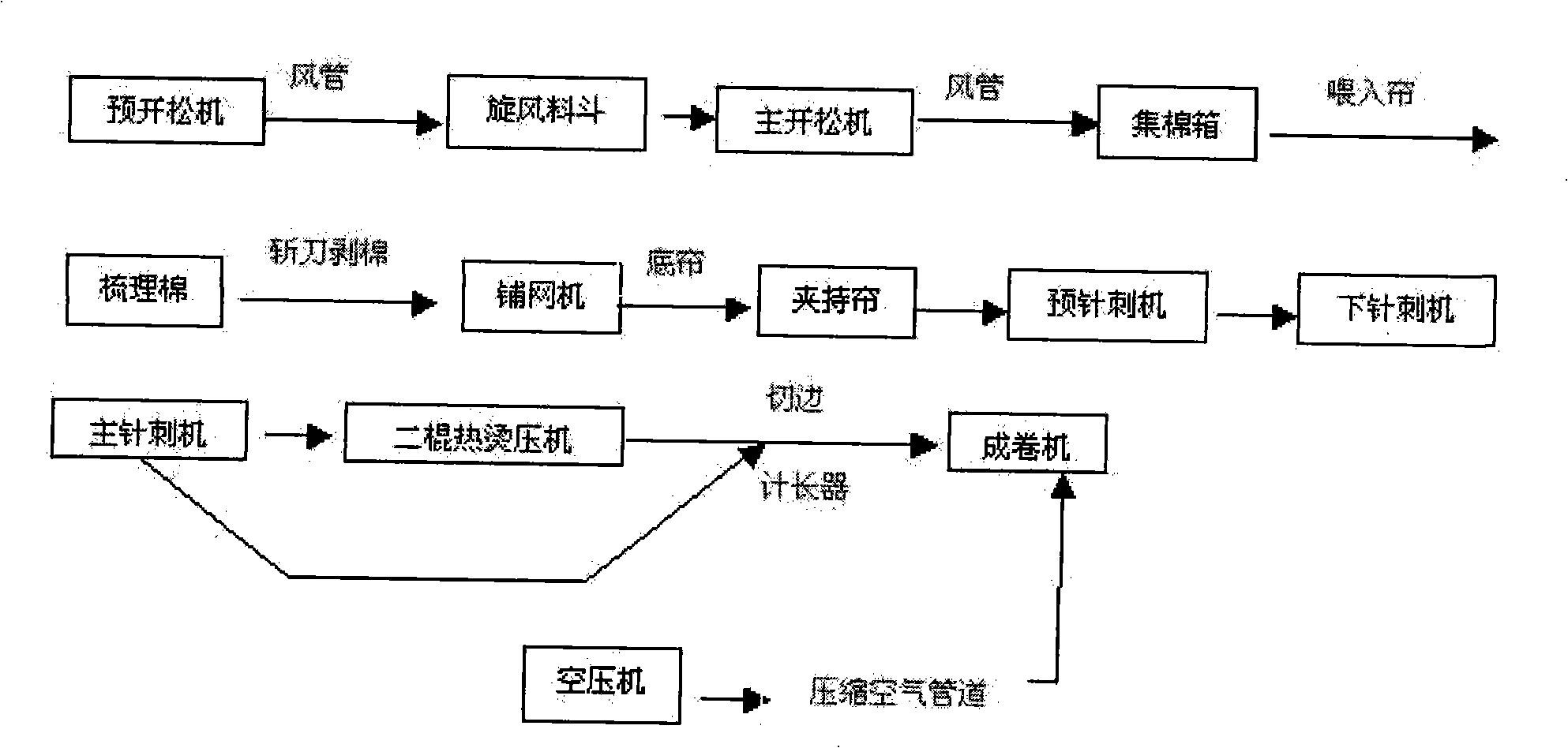

Filling cotton and preparation method thereof

InactiveCN101906700ALabor savingIncrease productivitySynthetic resin layered productsNon-woven fabricsProduction lineSurface layer

The invention discloses filling cotton and a preparation method thereof. The filling cotton comprises an upper needled surface layer and a lower needled surface layer, wherein a fiber web layer is arranged between the upper needled surface layer and the lower needled surface layer; and the upper needled surface layer, the fiber web layer and the lower needled surface layer are connected with one another through a strip-shaped needled band. The method comprises the following processing steps of: (1) needling raw materials of the upper needled surface layer and the lower needled surface layer by using a needling machine to prepare the upper needled surface layer and the lower needled surface layer; (2) putting raw materials of the fiber web layer into an opener for opening treatment; (3) carding the raw materials opened by the step (2) by using a carding machine to form planar netlike fibers; (4) laying the planar netlike fibers by using a lapping machine to form the fiber web layer and arranging the fiber web layer between the upper needled surface layer and the lower needled surface layer; and (5) needling the strip-shaped needled band by using the needling machine to obtain the filling cotton. The filling cotton is produced by a non-weaving process and can be produced on a large scale through a production line, and the elasticity and flexibility of a produced filling cotton product can meet market demands.

Owner:张延青

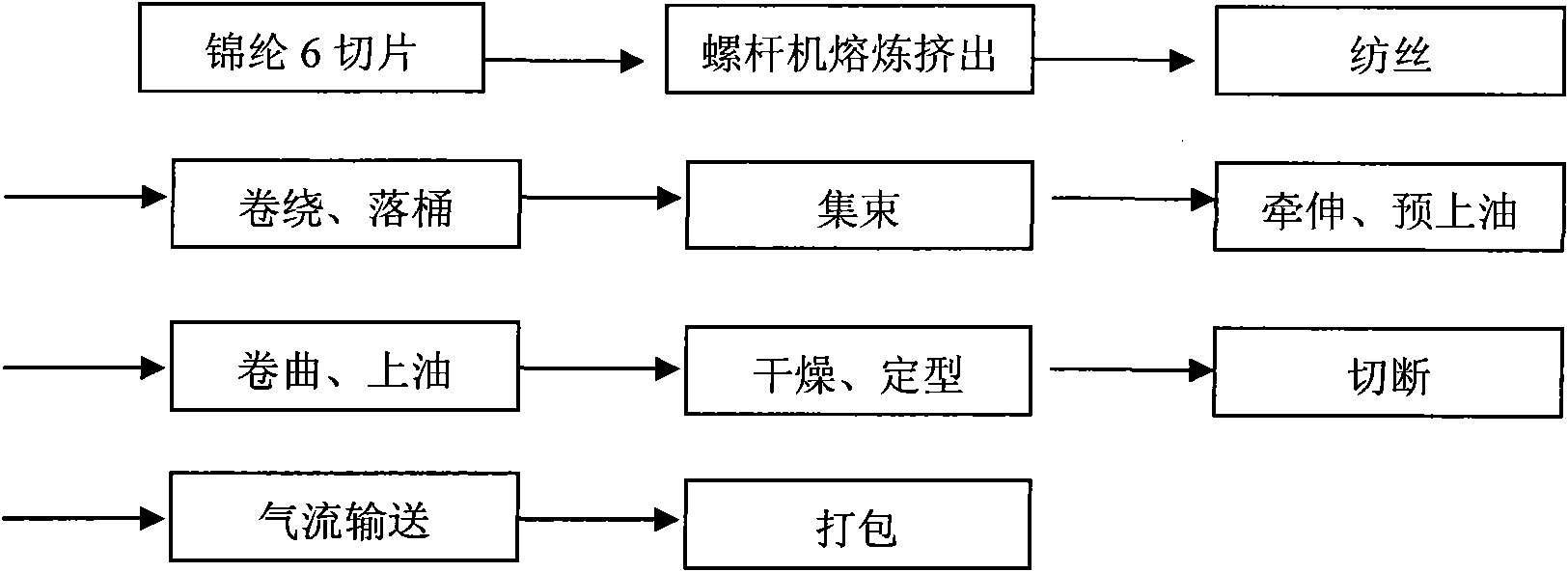

Process for producing full nylon leather base fabric

ActiveCN101671918AAvoid damageReduce accidental draftElectroconductive/antistatic filament manufactureFibre typesPolyesterNylon 6

The invention relates to a process for producing full nylon leather base fabric, comprising the following steps: (1) using nylon 6 slices as the raw material, adding antistatic master batches into thenylon slices and preparing antistatic nylon 6 short fibers by the following steps: melting and extruding by using a screw compressor, spinning, beaming, adjusting spinning finish formula and improving the finishing mode during finishing, drying and setting, cutting and the like; and (2) preparing the antistatic nylon 6 short fibers of the step (1) into the full nylon leather base fabric by adopting a needle-punched nonwoven fabric production process. The invention has the advantage that the full nylon leather base fabric prepared by the process for producing full nylon leather base fabric hasthe advantages of good flexibility, high tensile failure strength, good hydroscopic property, good skin feeling as well elasticity and the like compared with the regular nylon polyester blended leather base fabric.

Owner:HAINING HONGYUAN NON WOVEN FABRIC

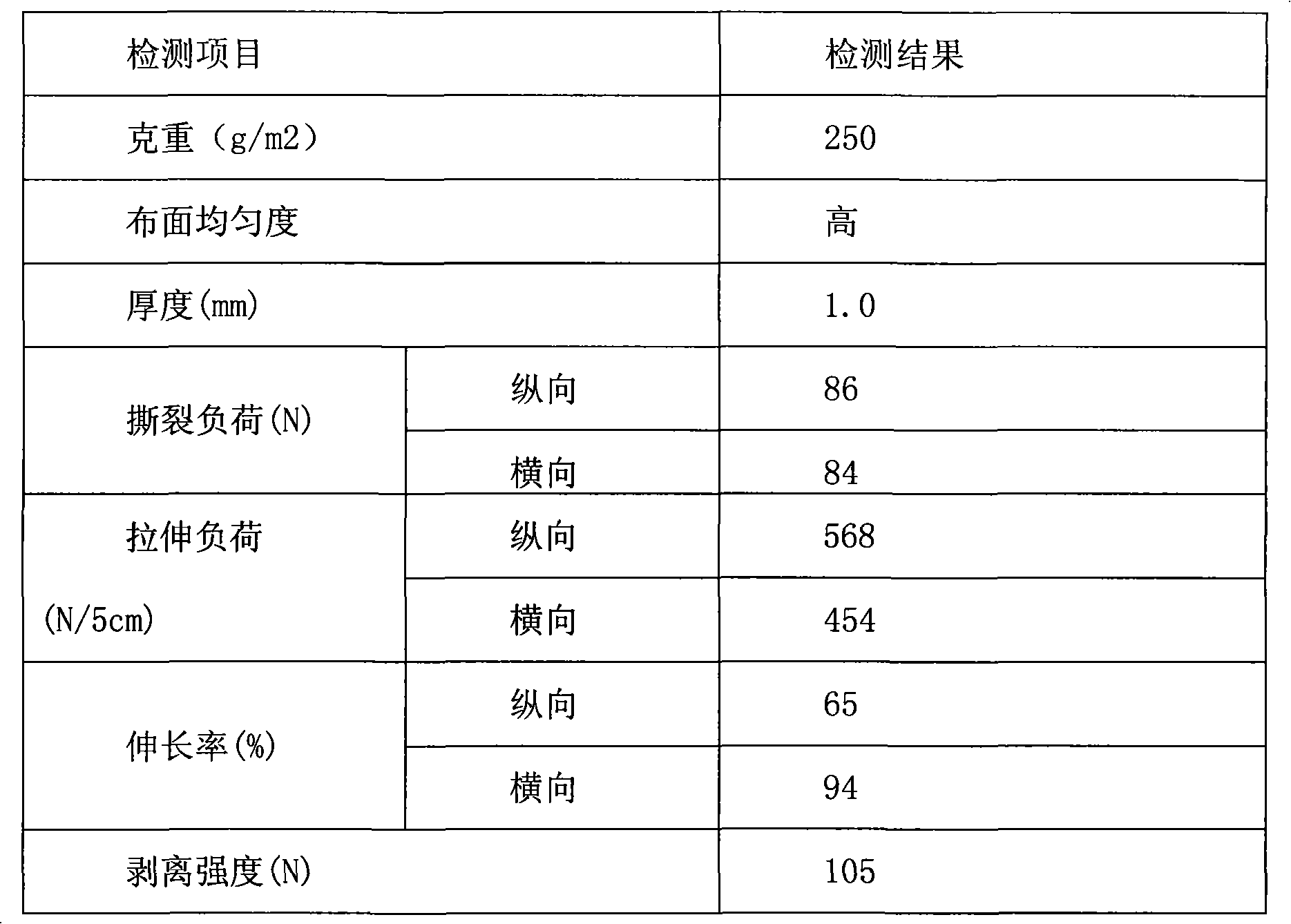

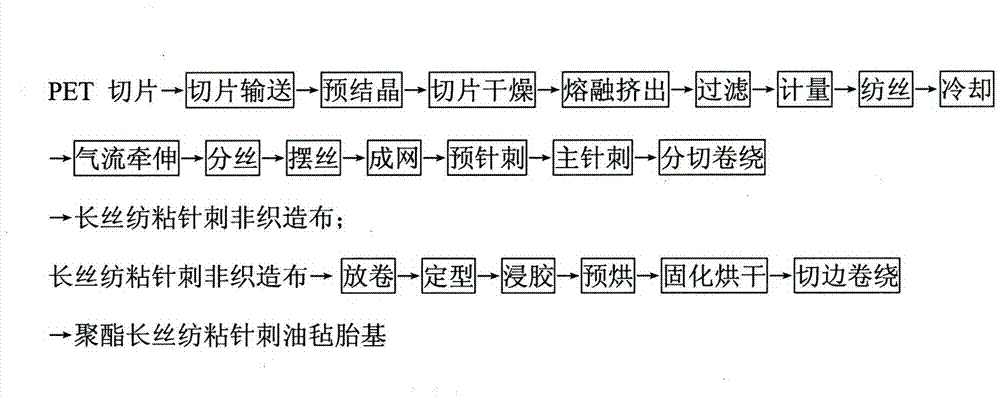

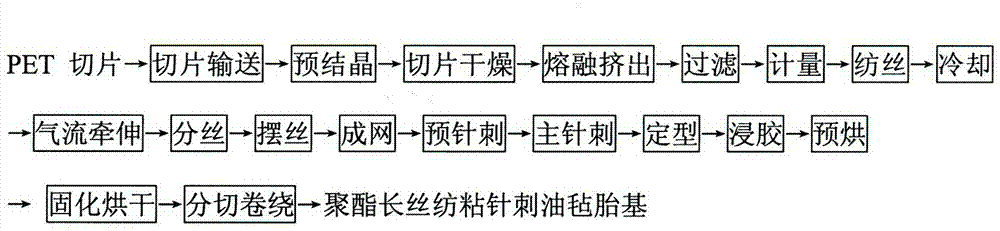

Production method of polyester filament spunbonded needle-punched felt base

ActiveCN103205902AGood orientationHigh crystallinityMelt spinning methodsNon-woven fabricsPolyesterEngineering

Owner:DALIAN HUAYANG NEW MATERIALS TECH CO LTD

Preparation method of figured islands-in-sea wool suedette interior trim leather of car

ActiveCN104963211AHas a pungent smellImprove breathabilityNon-woven fabricsPolyurethane dispersionChamois leather

The invention relates to a preparation method of figured islands-in-sea wool suedette interior trim leather of a car. The preparation method comprises the following steps: (a) opening 100% of 3.5Dx51mm Dacron figured islands-in-sea fibers through a nonwoven opening machine; (b) needling vertically so that the fibers are entangled and occluded to form a fabric; (c) transporting the fabric to a fibrewoven machine for surface finishing, and then ironing the fabric by adopting a heat roller with temperature of 110-120 DEG C at speed of 10-15m / min; (d) soaking the ironed fabric into polyving akohol solution with temperature of 80-90 DEG C and mass concentration of 8-10%, then soaking in waterborne polyurethane dispersoid, drying at 110-115 DEG C, and placing into deionized water with temperature of 80-95 DEG C for removing polyvinyl alcohol, thus obtaining suedette, namely Beth; (e) soaking the Beth into NaOH or KOH solution with mass concentration of 5-10%, wherein the pick-up ratio is 100%; adjusting the pH till the pH is neutral, and drying; (f) dyeing and drying; and (g) carrying out sanding treatment. With the adoption of the preparation method, polyvinyl alcohol can be removed in alkaline solution, and thus the suedette interior trim leather with good breathability is obtained.

Owner:江苏尚科聚合新材料有限公司

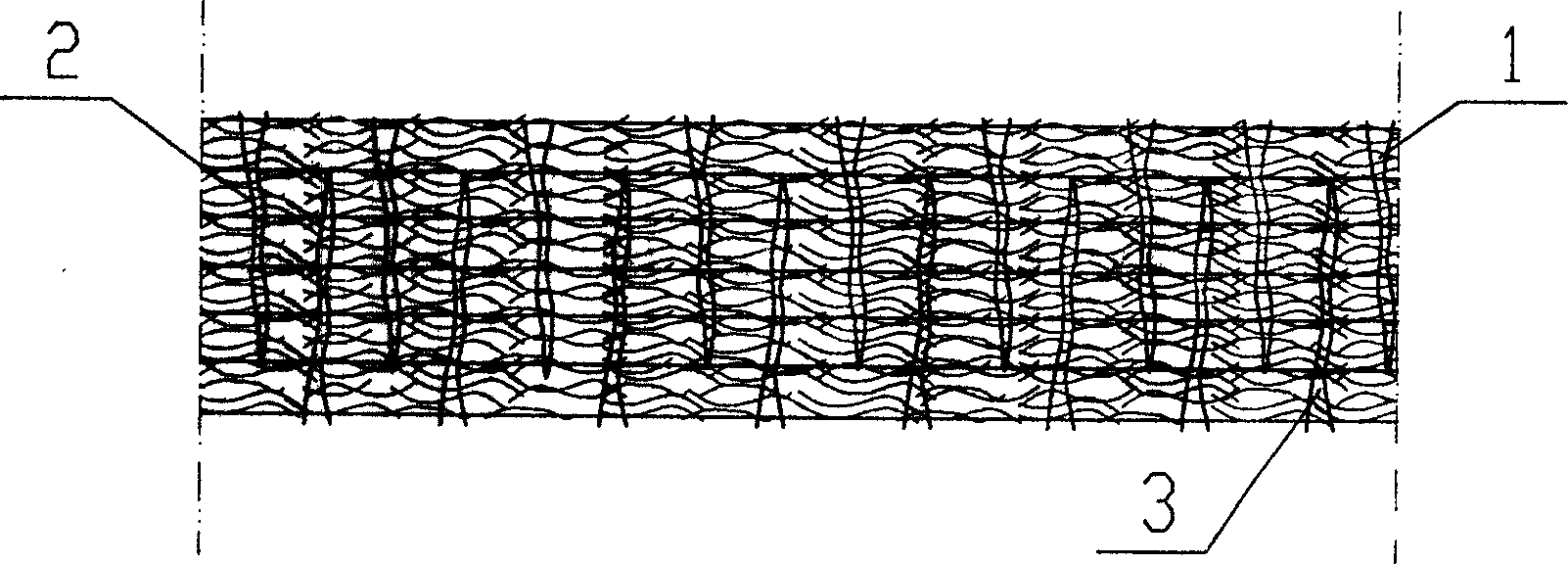

Fibre layered article composite product and production method thereof

The invention discloses a fiber layer shape composite product and a production method thereof. The fiber layer shape composite product is composed of superposition and connection of a glass fiber layer, synthesized fiber needling felt and a reinforced fiber layer. The synthesized fiber needling felt is positioned in the middle of the glass fiber layer and the reinforced fiber layer. The production method is that: 1. the synthesized fiber needling felt is produced with porosity of 50 to 90 percent and a single fiber diameter of 80 to 100Mum; 2. the polyester hemming-stitching thread is warped into a warp beam; 3. the glass fiber layer, the synthesized fiber needling felt and the reinforced fiber layer are sent into a hemming-stitching mechanism, and the polyether hemming-stitching thread is sent into the hemming-stitching mechanism by a frequency conversion automatic let-off mechanism; 4. in the hemming-stitching mechanism, layers of the materials are hemming-stitched into the fiber layer shape composite product only one time. The fiber layer shape composite product of the invention is applicable to the closed mold forming techniques such as RTM and VARTM, etc. which has the advantages of being easy to design, simple technique and high work efficiency.

Owner:CHANGZHOU TIANMA GROUP CO LTD

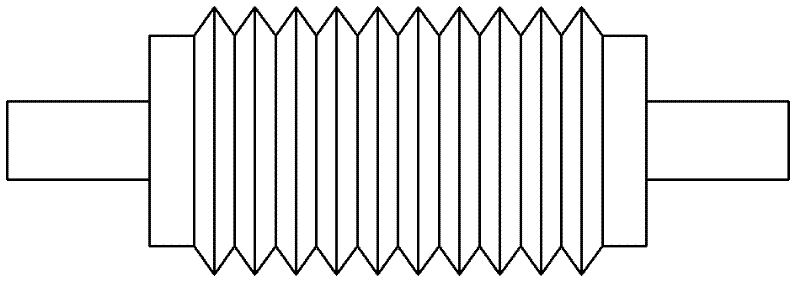

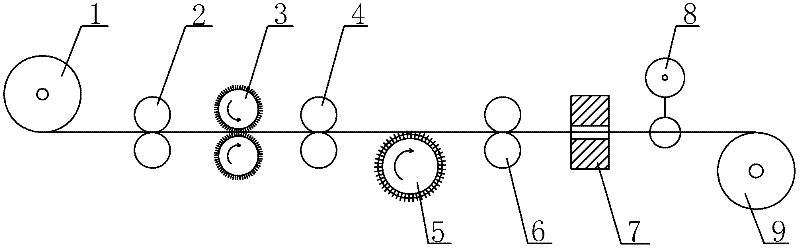

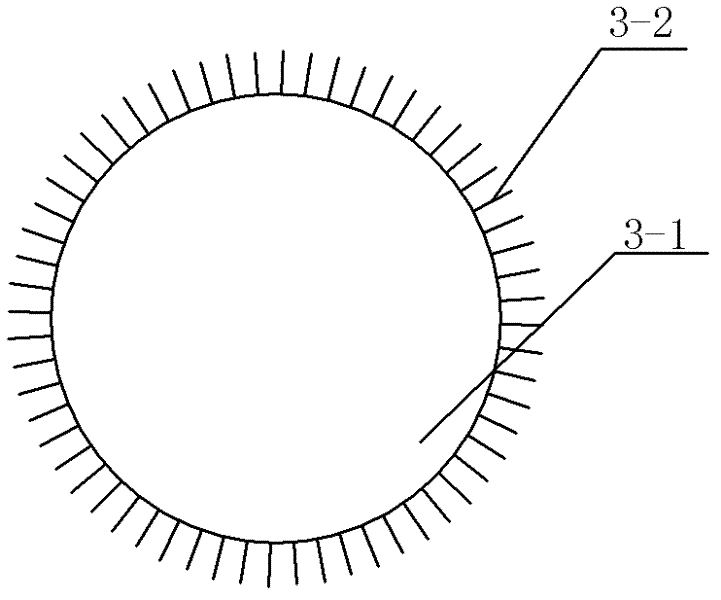

Complete device for manufacturing polytetrafluoroethylene (PTFE) short fiber in acupuncture comb-cutting method and method thereof

ActiveCN102517665ALess investmentCheap to manufactureArtificial thread manufacturing machinesFilament/thread formingEngineeringMechanical engineering

The invention relates to a device for manufacturing a short fiber, in particular to a complete device for manufacturing a polytetrafluoroethylene (PTFE) short fiber in an acupuncture comb-cutting method and a method thereof. The complete device comprises an oriented film unwinding mechanism, a pair puncture needle roller for puncturing an oriented film, a comb-cutting roller combing and cutting the punctured oriented film into filaments, a buncher bunching the filaments, a traversing gear and a winding mechanism which are all arranged in sequence, wherein the winding mechanism is used for winding a filament bundle. Compared with a film breaking processing process widely adopted at present, the complete device for manufacturing the PTFE short fiber in the acupuncture comb-cutting method and the method thereof have the advantages that the process is simple, reasonable and reliable, operation is convenient, energy consumption is little, efficiency is high, and the device and main parts are low in manufacturing cost, little in investment and low in maintenance cost. The PTFE short fiber with thinner fineness can be produced, the average fineness can reach 2.5dtex at minimum, and production varieties are expanded.

Owner:常州华福环境科技股份有限公司

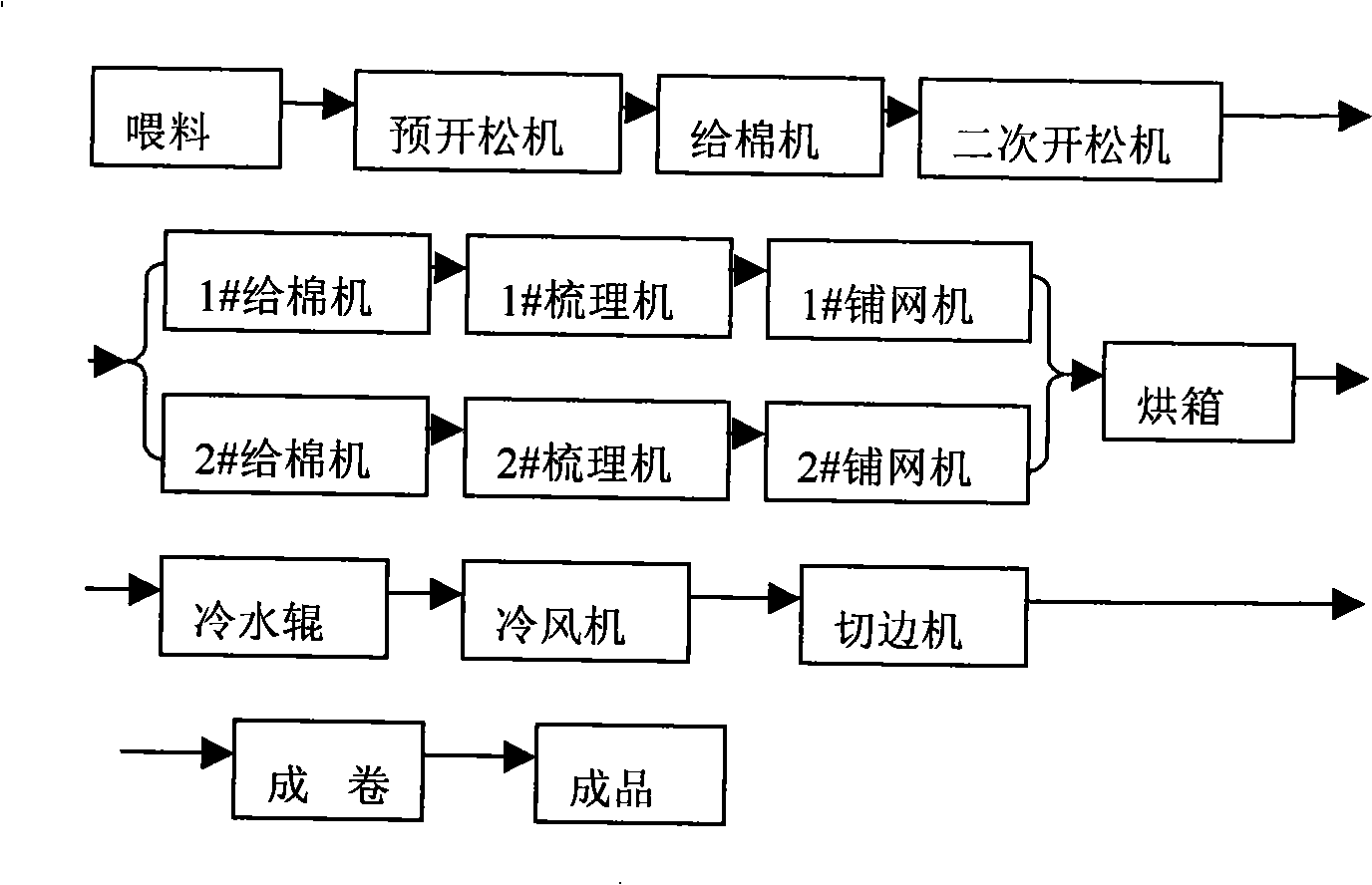

Environmentally friendly differential fiber non-woven automotive interior trim material and preparation method thereof

ActiveCN101851863AImprove spinnabilityAvoid it happening againFibre typesNeedling machinesFoam rubberEngineering

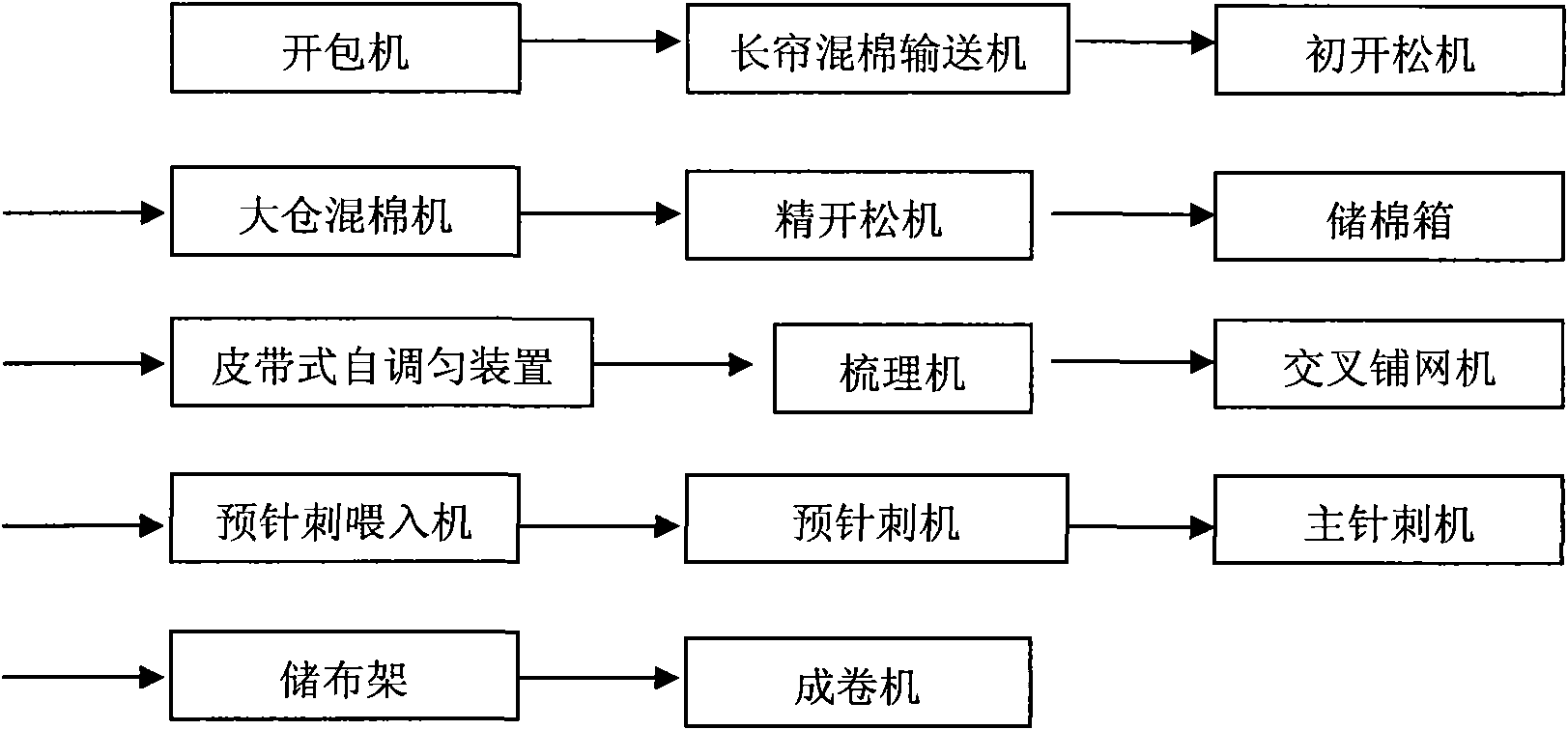

The invention belongs to automotive non-woven textiles, in particular to an environmentally friendly differential fiber non-woven automotive interior trim material and a preparation method thereof. The preparation method comprises the following steps of: preparing needle-punched grey cloth through feeding fibers, roughly opening, mixing fibers, fine opening, carding the fibers into a net, crosswise spreading the net and needling by using environmentally friendly colored flame retardant terylene short fibers as a raw material; and then carrying out foam gum dipping in flame retardant polyacrylate foaming rubber latex to obtain the differential fiber non-woven automotive interior trim material, wherein the adhesion quantity of the rubber latex is controlled to be 12-18g / m<2>. The environmentally friendly differential fiber non-woven automotive interior trim material has good property, high quality, environmental protection and high safety; and the preparation method provided by the invention has low energy consumption, no pollution and low cost.

Owner:福建福能南纺卫生材料有限公司

Weaving method of carbon fiber preform of automobile brake disc

ActiveCN109795180AReduce wasteImprove thermal efficiencyLayered productsNon-woven fabricsGraphiteMaterials science

The invention relates to a weaving method of a carbon fiber preform of an automobile brake disc, and belongs to the technical field of carbon fiber composite material reinforcement weaving. The methodincludes the following steps: (1) preparing a carbon fiber plain cloth; (2) preparing a carbon fiber net tire; (3) sewing the carbon fiber plain cloth of step (1) and the carbon fiber net tire of step (2) together to form a plain-mesh tire cloth; and (4) winding the plain-mesh tire cloth obtained in the step (3) for a plurality of circles along the circumferential direction of a graphite sleeve,and needling once in each winding circle until the size requirement of the carbon fiber preform is met to form the carbon fiber preform, wherein the weight percentage of the carbon fiber plain cloth in the carbon fiber preform is more than or equal to 67%, and the weight percentage of the carbon fiber net tire is less than or equal to 33%. The preparation method is safer, the fiber waste quantityis less, the thermal conductivity in the thickness direction of the product can be ensured to be higher, the internal phase of the material is more uniform, and the friction surface is smoother and more beautiful.

Owner:山东道普安制动材料有限公司

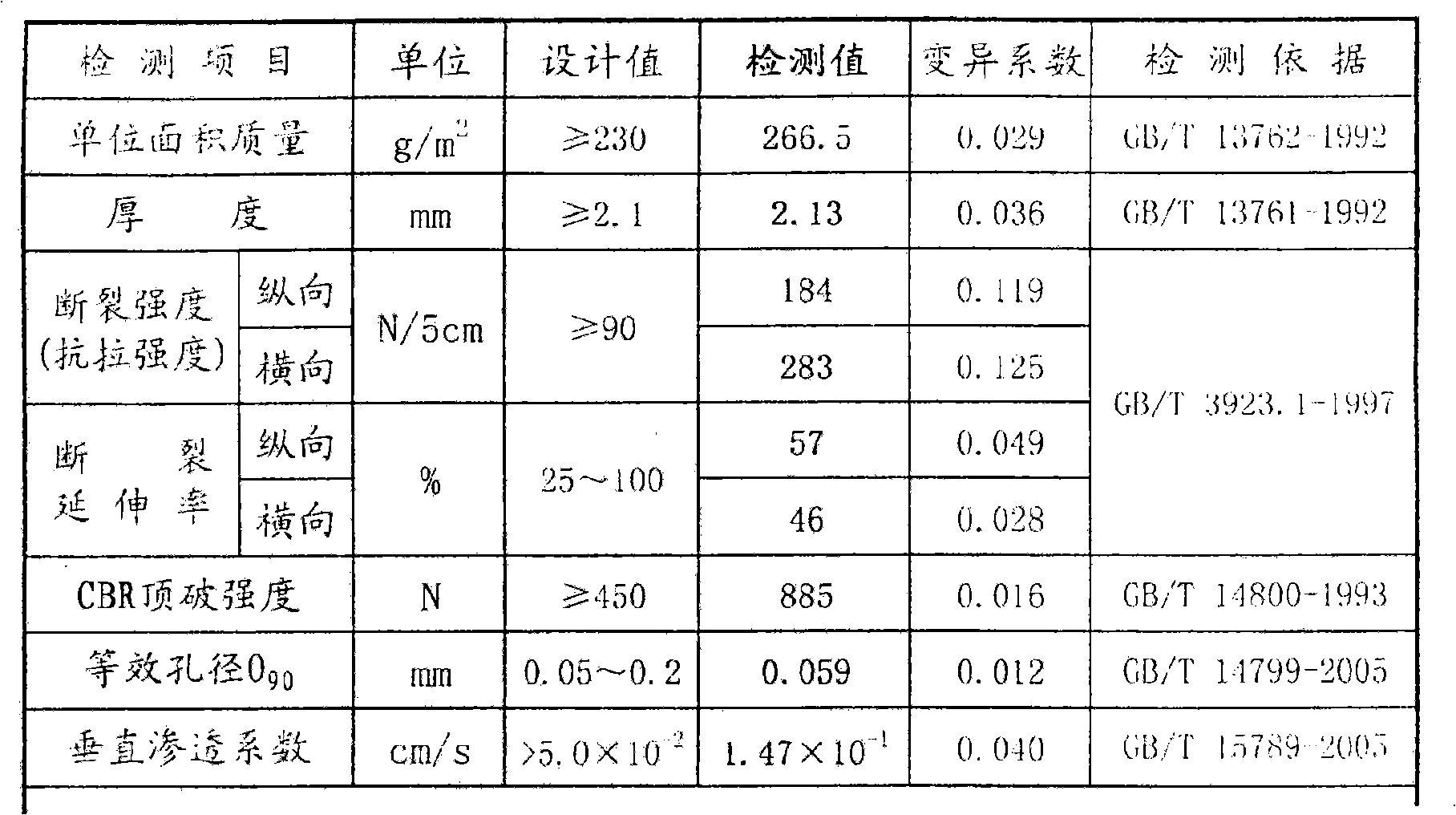

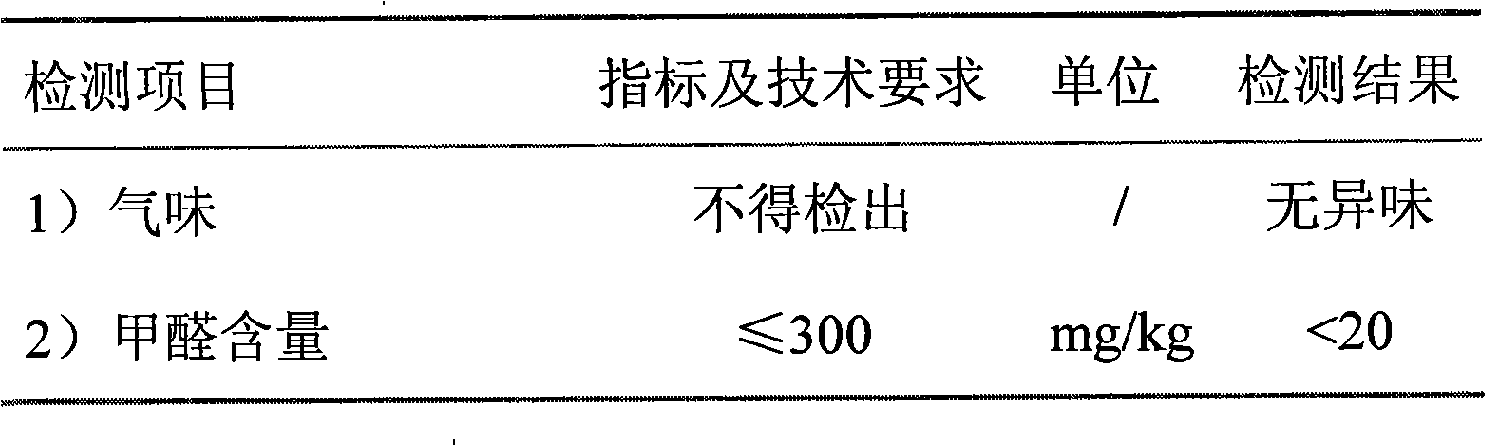

Geotextile and method for manufacturing same

The invention relates to an earth work fabric, and also relates to the manufacturing method of the earth work fabric. An earth work fabric is characterized in that the earth work fabric is a needled non-woven which completely takes viscose fiber as the raw materials. The manufacturing method of the earth work fabric comprises the steps of: opening, mixing, carding, forming a web, paving the web, needling, lapping; the method is characterized in that: the steps are carried out at the normal moisture and normal temperature; the needling comprises pre-needling, secondary-needling, tertiary-needling, the frequency of pre-needling is 500+ / -50 times / minute, the depth of pre-needling is 7mm+ / -0.5, the lapping speed is 2-3metres / minute; the frequency of secondary-needling is 600+ / -50 times / minute, the depth of pre-needling is 6.5mm+ / -0.5, the lapping speed is 2-3metres / minute; the frequency of the tertiary-needling is 600+ / -50 times / minute, the depth of pre-needling is 3.5-4mm, the lapping speed is 2-3metres / minute.

Owner:SHANGHAI NEW TECHTEXTILES

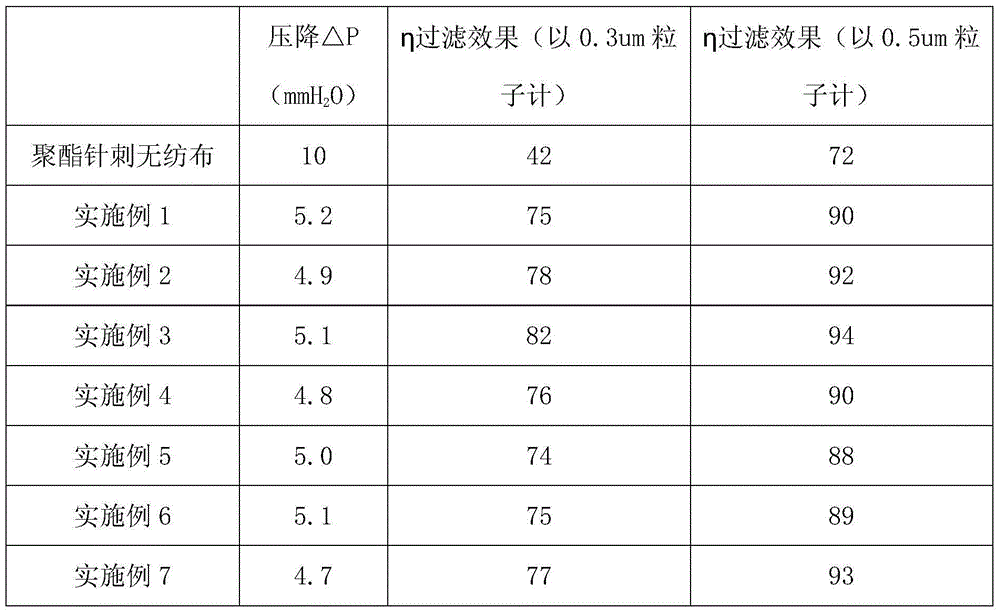

Profiled fiber non-woven fabric and manufacturing method thereof

InactiveCN104911809ALarge specific surface areaImprove breathabilityNon-woven fabricsAir filtrationManufacturing technology

The invention belongs to the field of functional textile materials and discloses profiled fiber non-woven fabric and a manufacturing method thereof. Short profiled fiber and non-profiled fiber are taken as the base material and dispersed and mixed into a mixed fiber layer according to a certain mass ratio, and then lapping, needling or spunlace processing and hot pressing are conducted so as to obtain the profiled fiber non-woven fabric. The manufacturing method has the advantages that manufacturing technology is simple, and the hardness of the manufactured non-woven fabric is controllable. The manufactured non-woven fabric contains polymer fiber, can be widely applied to air filtration, metallurgy and the like, and has the advantages of being low in cost and wide in application range.

Owner:佛山市维晨科技有限公司

Thermoplastic fiber enhanced plastic plate and manufacturing method thereof

A thermoplastic fiber reinforced plastic board and its production is disclosed. It consists of insoluble fiber 15-60 wt% and plastic fiber 40-85 wt%. The process is carried out by mixing insoluble fiber with plastic fiber by non-woven producer, finish forming, acupuncturing to obtain fiber felt, cutting into blocks in size, coinciding, delivering it into hot press, hot pressing and forming to obtain final product.

Owner:蒋姝华 +1

Preparation technology of alkali-resisting PTFE (polytetrafluoroethylene) and PPS (polyphenylene sulfide) fiber blended needled felt

InactiveCN110130116ASmall filter resistanceImprove breathabilitySolvent-treatmentNon-woven fabricsEmulsionFiltration

The invention belongs to the technical field of industrial dedusting application and particularly discloses a preparation technology of alkali-resisting PTFE (polytetrafluoroethylene) and PPS (polyphenylene sulfide) fiber blended needled felt. The preparation technology comprises following steps: step 1, fiber opening; step 2, fiber carding; step 3, lapping; step 4, needling compaction; step 5, postprocessing: (1), calendering; (2), singeing; (3), impregnation with an emulsion; (4), high-temperature setting; (5), film covering. The preparation technology of the alkali-resisting PTFE and PPS fiber blended needled felt has beneficial effects as follows: 1, a PTFE fiber+PPS fiber needled felt filter material is a filter material with a stereoscopic fiber structure, and the filter material isformed by covering two sides of base cloth with stereoscopically staggered PTFE fibers and PPS fibers respectively, compacting and fixing the base cloth and then needling the base cloth by a needlingmachine; 2, the needled felt filter material has a small bore diameter, low filtration resistance, good breathability and high dust capturing efficiency. The filtration efficiency can reach 99.99% orabove.

Owner:JIANGSU XI YANGYANG ENVIRONMENTAL PROTECTION EQUIP SCI & TECH CO LTD

Super-thick glass fiber needle-punched felt and method for manufacturing same

InactiveCN101012600AIncreasing the thicknessImprove bindingGlass making apparatusFelting apparatusGlass fiberFiltration

The invention discloses an extra-thick needle felt of glass fiber, comprising multiple felt layers of glass fiber piling up together. Vertical short fibers formed by needle are set among said multiple felt layers. The vertical short fiber comprises the upper vertical short fiber, which interludes in the multiple felt of glass fiber from the upper face, and the lower vertical short fiber, which interludes in the multiple felt of glass fiber from the lower face. The thickness of said needle felt is 20-50mm. the setting of bidirectional vertical fiber guarantees that the combination of each layer of needle felt is fastness under the status of needle felt with larger thickness. So the invention is not only provided with good temperature resistance and anticorrosion properties but also selective absorption property for gas and liquid. Because of larger thickness and improved intensity, properties such as heat separation, heat preservation and filtration so on are improved.

Owner:李洪贤

Absorbent non-woven felt material and method of making same

InactiveUS7501364B2Promote absorptionReadily containsAbsorbent padsBaby linensMaterials scienceSynthetic fiber

Owner:BOUCKAERT INDAL TEXTILES

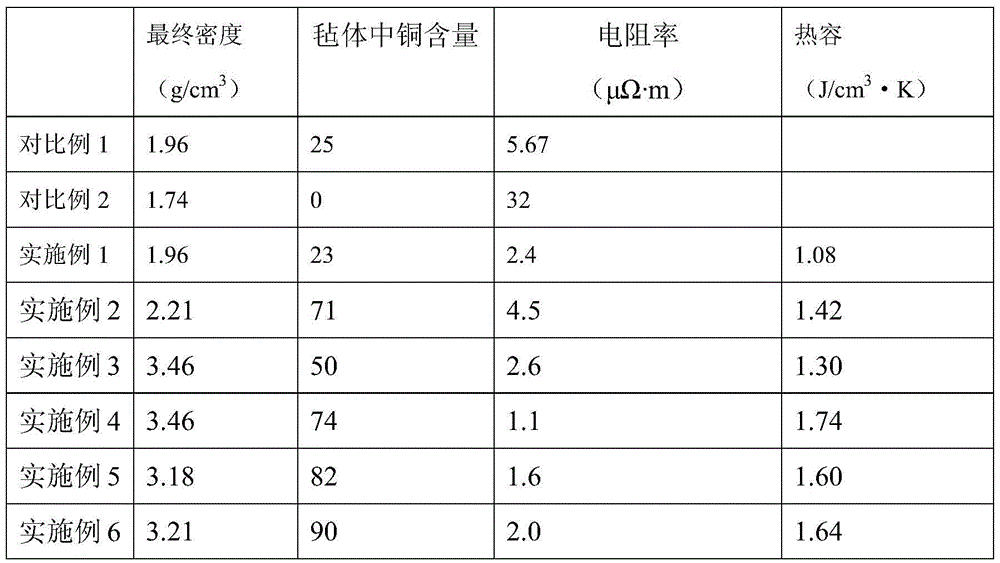

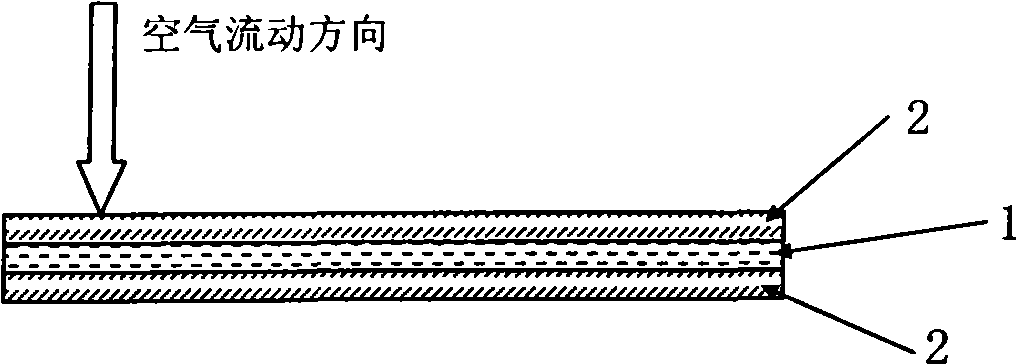

Preparation method of metal-type C/C composite material carbon slide strips

The invention relates to a preparation method of metal-type C / C composite material carbon slide strips, and belongs to the technical field of electric locomotive material preparation. The preparation method comprises following steps: single-layer 0 DEG no-woven carbon cloth, carbon fiber felt, graphite powder, a copper material, the single-layer 90 DEG no-woven carbon cloth, carbon fiber felt, graphite powder, the copper material, and the single-layer 90 DEG no-woven carbon cloth are overlapped successively in a circulation manner, relay-type needling is adopted to introduce carbon fiber bundles in a direction vertical to a layer direction so as to obtain a 2.5D carbon fiber needled integrated felt with a density ranging from 0.6 to 2.6g / cm3, and the 2.5D carbon fiber needled integrated felt is subjected to chemical vapor deposition pyrolysis carbon treatment so as to obtain a C / C-Cu composite material; and at last the C / C-Cu composite material is subjected to machining based on designed slide strip size, allowance for machining is put on reserve, and polymer steeping-carbonization treatment is carried out so as to obtain a finished product. The preparation method is simple; and the obtained metal-type C / C composite material possesses relatively low electrical resistivity and high thermal capacity.

Owner:杭州卓导新材料有限公司

Polytetrafluoroethylene punched felt and manufacturing method thereof

ActiveCN101805958AHigh saturationReduce voidsHeating/cooling textile fabricsNon-woven fabricsMaterial consumptionEngineering

The invention relates to a polytetrafluoroethylene punched felt. From the outside to the inside, the structure of the punched felt comprises a polytetrafluoroethylene crimped staple layer, a polytetrafluoroethylene filament base fabric and a polytetrafluoroethylene crimped staple layer, wherein the thickness of the punched felt ranges from 0.8 to 1.8 millimeters; polytetrafluoroethylene crimped staples mutually hooked and crossed are inserted in the base fabric from upside and downside and tightly connected with the base fabric. The punched felt produced by the invention has the advantages of stable chemical properties, high filtering effect, high strength, low heating shrinkage, low material consumption, low cost, no smoke pollution and the like.

Owner:常州华福环境科技股份有限公司

Polytetrafluoroethylene fibre and glass fibre combined nonwoven filtering felt and preparation method thereof

The invention relates to a non-woven filter felt combined by air net forming and prickling reinforcement and compounded by polyfluortetraethylene fiber and glass fiber. The non-woven filter felt has a layered structure, the middle layer is provided with high-strength low stretching base cloth, and the upper surface and the lower surface of the high-strength low stretching base cloth are symmetrically adhered with fiber surface layers. Manufacturing steps comprise manufacturing of a surface air forming net, manufacturing of a base layer, manufacturing of a prickling felt, soaking, calendaring, coating, preliminary drying, curing and solidifying, trimming, winding, product finishing. The non-woven filter felt has the advantages of improvement on the service life of the filter felt by adopting an air net-forming fiber surface layer to replace a carding net-forming fiber surface layer of a carding machine, high filter efficiency, high physical and mechanical properties, economic cost, even and smooth surface, little fiber damage ratio and evener net formation.

Owner:SHANGHAI BG INDAL FABRIC

Superabsorbent composite fiber and preparation method thereof

ActiveCN105544002AFast water absorptionSimple processConjugated cellulose/protein artificial filamentsWet spinning methodsNonwoven fabricChemistry

The invention discloses a superabsorbent composite fiber and a preparation method thereof. The fiber component comprises a sodium carboxymethylcellulose and alginate, wherein the content of sodium carboxymethylcellulose is not less than 70%. The preparation method of the fiber uses sodium carboxymethyl cellulose (hereinafter referred to as CMC) as the main raw material and alginate (hereinafter referred to as SA) as an auxiliary material; a wet spinning process is employed; a mixed solution of a volatile organic solvent containing a proper amount of water and calcium chloride and / or zinc chloride is used as a coagulation liquid; and a volatile organic solvent containing an appropriate amount of water is used a drawing / washing liquid. The prepared composite fiber has the advantages of high water-absorbing speed, high water absorption and water absorption into the gel, and can be prepared into acupunctured non-woven fabric or blend of hot air non-woven fabric for medical dressings, sanitary napkins, diapers, incontinence pads and other disposable medical supplies.

Owner:厦门百美特生物材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com