Environmentally-friendly multifunctional insole and production process thereof

A production process and multi-functional technology, applied to insoles, footwear, layered products, etc., can solve the problems of not achieving beneficial effects, poor air permeability of insoles, and beriberi, etc., and achieve the effect of simple and feasible production process and good elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

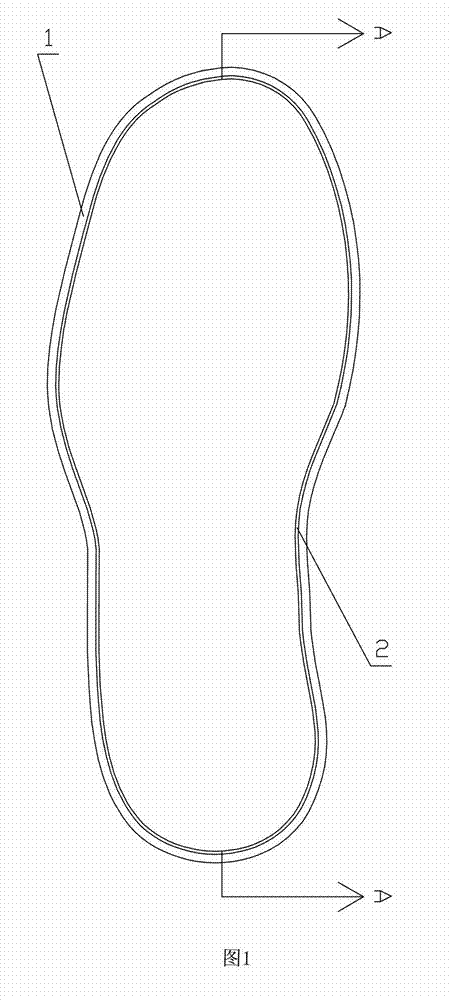

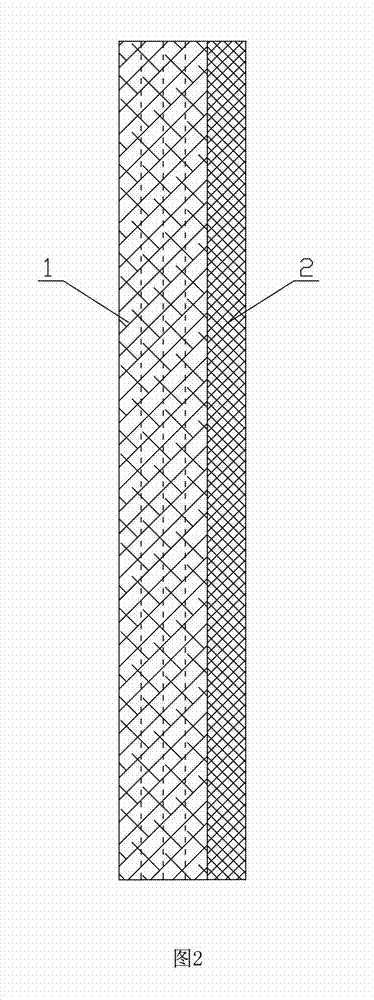

[0024] refer to figure 1 with figure 2 , an environmentally friendly and breathable insole, comprising a base layer 1 and a surface layer 2, the base layer 1 is a high-density needle-punched non-woven fabric made of bamboo charcoal fiber and far-infrared polyester, and the ratio of bamboo charcoal fiber to far-infrared polyester by weight fraction It is composed of bamboo charcoal fiber: far-infrared polyester = 1:1, and the surface layer can be warp-knitted according to needs.

[0025] refer to figure 1 , the surface layer 2 is glued on the base layer 1 with an environment-friendly acrylic glue, and the surface layer 2 can also be sewn on the base layer 1 .

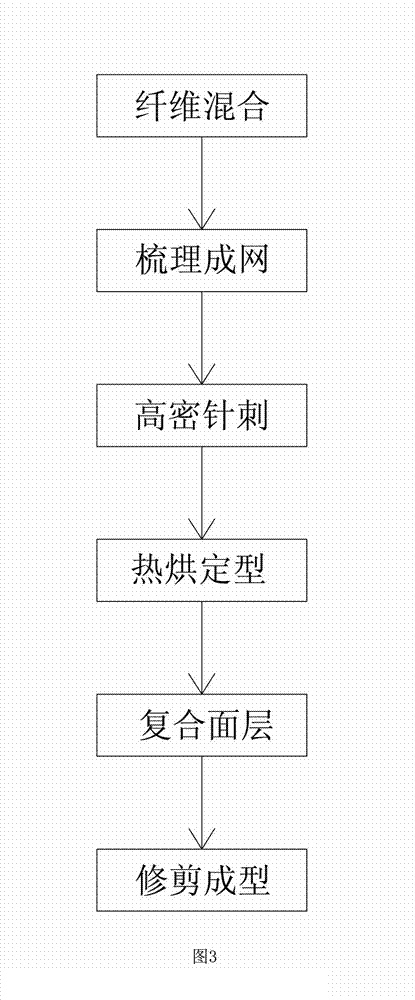

[0026] refer to image 3 , the production process of the environment-friendly breathable insole includes the following steps: take a predetermined amount of bamboo charcoal fiber and far-infrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com