Process for producing full nylon leather base fabric

A production process, nylon technology, applied in the production process of all-nylon leather base cloth, can solve the problems of difficult spinning or dyeing, poor resin compatibility, high cost, etc., to reduce fiber damage, reduce free draft ratio, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with specific examples: this example is implemented on the premise of the technical solution of the present invention, and detailed implementation manners and processes are given, but the protection scope of the present invention is not limited to the following examples.

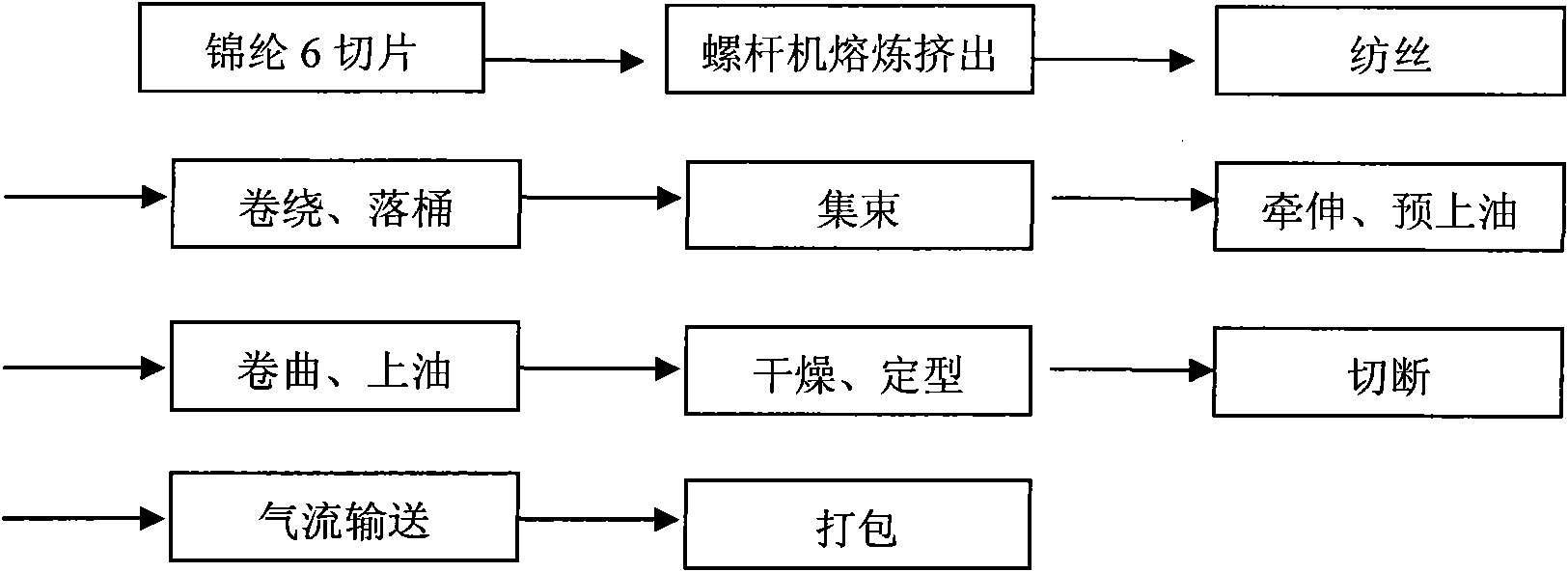

[0038] Reference figure 1 , An antistatic nylon staple fiber prepared by the following method:

[0039] (1) Mix nylon 6 chips with antistatic masterbatch in a weight ratio of 90~99:1~10;

[0040] (2) The above mixture is fed into the screw extruder with electric heating function through the silo to make the slices melt;

[0041] (3) The above-mentioned molten material is quantitatively pressed into the spinning assembly through a metering pump, and ejected from the spinneret, and the spun filament is cooled and crystallized to obtain the primary growth filament;

[0042] (4) The nascent yarn is wound, doffed, bundled, drafted, pre-oiled, crimp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com