Lightweight and environment-friendly type fibrilia composite plate and preparation method thereof

An environmentally friendly technology of hemp fiber, which is applied in the field of lightweight and environmentally friendly hemp fiber composite board and its preparation, can solve the problems of difficult to remove odor, heavy quality, dampness, and mildew, etc., to improve tensile strength and reduce density , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

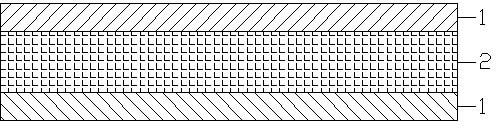

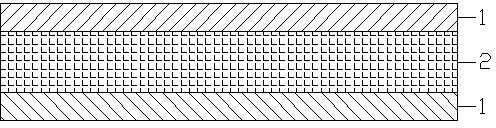

[0022] see figure 1 , a kind of lightweight environment-friendly hemp fiber composite board that the present invention relates to, it comprises PE film layer 1 and hemp fiber felt layer 2, and described hemp fiber felt layer 2 is the middle layer, and its upper and lower surfaces are compounded with PE film Layer 1.

[0023] Described hemp fiber felt layer 2 is a needle-punched hemp fiber felt, and its components and their mass ratios are as follows:

[0024] Hemp fiber 55%, PP fiber 45%.

[0025] The preparation method of the lightweight environment-friendly hemp fiber composite board of the present invention is as follows:

[0026] The first step: hemp fiber treatment

[0027] Soak the harvested hemp fiber raw material in caustic soda solution for 20-25 days, pickle and wash with water, and then go through peeling→drying→opening→rolling→cutting to make crude hemp fiber;

[0028] After rinsing→drying→finishing and loosening the crude hemp fiber, it is ready for use;

[0...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that the hemp fiber mat layer 2 is a needle-punched hemp fiber mat, and its components and their mass ratios are as follows: hemp fiber 60%, PP fiber 40%.

[0036] The finished product has no peculiar smell, is light in weight and has a density of 0.31g / cm 3 , the tensile strength reaches 3.72MPa, and the flexural elastic modulus reaches 187.7MPa.

Embodiment 3

[0038] The difference between this embodiment and embodiment 1 is that the hemp fiber felt layer 2 is a needle-punched hemp fiber felt, and its components and their mass ratios are as follows: hemp fiber 65%, PP fiber 35%.

[0039] The finished product has no peculiar smell, is light in weight and has a density of 0.36g / cm 3 , the tensile strength reaches 3.68MPa, and the flexural modulus reaches 189.7MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com