Complete device for manufacturing polytetrafluoroethylene (PTFE) short fiber in acupuncture comb-cutting method and method thereof

A technology of PTFE and complete sets of equipment, which is applied in the field of equipment for manufacturing short fibers, can solve the problems of difficult manufacturing and processing, high maintenance cost, and high precision requirements, and achieve the effects of low production price, low maintenance, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

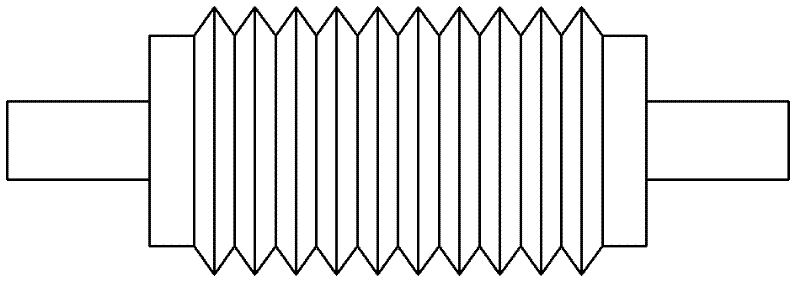

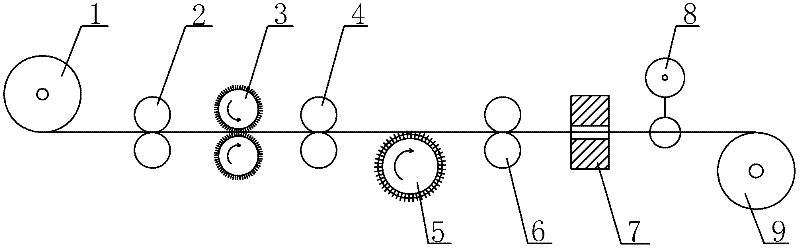

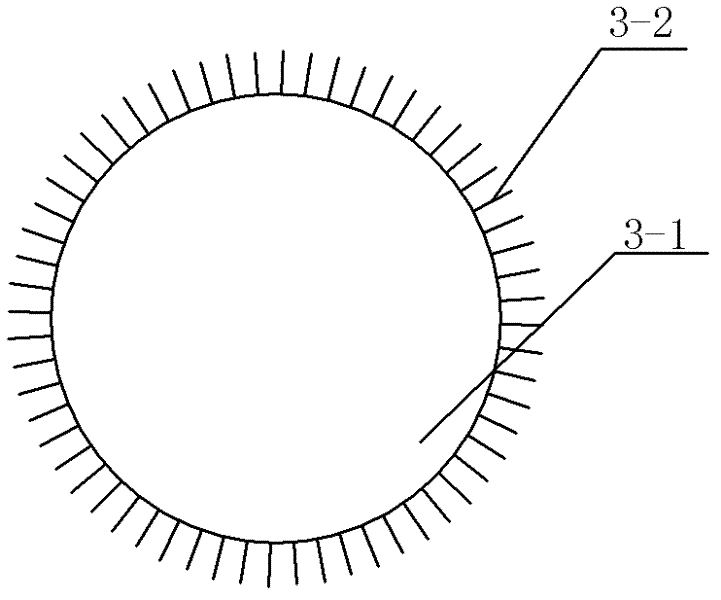

[0032] Such as figure 2 , 3 , shown in 4, the needle punching and carding method of the present invention manufactures the PTFE short fiber complete set of equipment and method thereof, comprises the unwinding mechanism 1 that is wound with oriented film that is arranged successively, the first pair of rubber holding rollers 2, the pair of oriented film A pair of piercing needle rollers 3 engaged up and down for puncturing, the second pair of rubber holding rollers 4, combing rollers 5 for combing the punctured oriented film into long filaments, the third pair of rubber holding rollers 6, and the filaments Concentrator 7, traversing device 8 and winding mechanism 9 for winding filament bundles, piercing needle roller 3 has a roller body 3-1, and the outer circumferential surface of roller body 3-1 has piercing steel needles closely arranged Needle 3-2, puncture steel needle 3-2 diameter is 0.3mm, needle length is 15mm, needle tip area is 0.0005mm 2 , the row pitch of punctu...

Embodiment 2

[0042] Such as figure 2 , 3 , shown in 4, the needle punching and carding method of the present invention manufactures the PTFE short fiber complete set of equipment and method thereof, comprises the unwinding mechanism 1 that is wound with oriented film that is arranged successively, the first pair of rubber holding rollers 2, the pair of oriented film A pair of piercing needle rollers 3 that mesh up and down, a second pair of rubber gripping rollers 4, a carding roller 5 that combs the punctured oriented film into long filaments, and a third pair of rubber grips that are punctured and arranged above and below the oriented film. Holding roller 6, bundler 7 that bundles filaments, traversing device 8 and winding mechanism 9 that winds filament bundles, piercing needle roller 3 has roller body 3-1, the outer circumference of roller body 3-1 There are closely arranged puncture steel needles 3-2 on the surface, the diameter of puncture steel needles 3-2 is 0.4mm, the needle len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Needle length | aaaaa | aaaaa |

| Needle length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com