Weaving method of carbon fiber preform of automobile brake disc

A carbon fiber preform, automotive braking technology, applied in non-woven fabrics, textiles and papermaking, layered products, etc., can solve the problems of the decrease of the strength of the brake disc preform, the influence of friction performance, the decrease of the temperature of the disc surface, etc., and achieve good application. Prospects, improve conductivity, heat dissipation and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for weaving a carbon fiber prefabricated body of an automobile brake disc. The prepared carbon fiber prefabricated body is in the shape of a ring, with an outer diameter of 392mm, an inner diameter of 143mm, and a thickness between the upper and lower sides of 43mm. The weaving method includes:

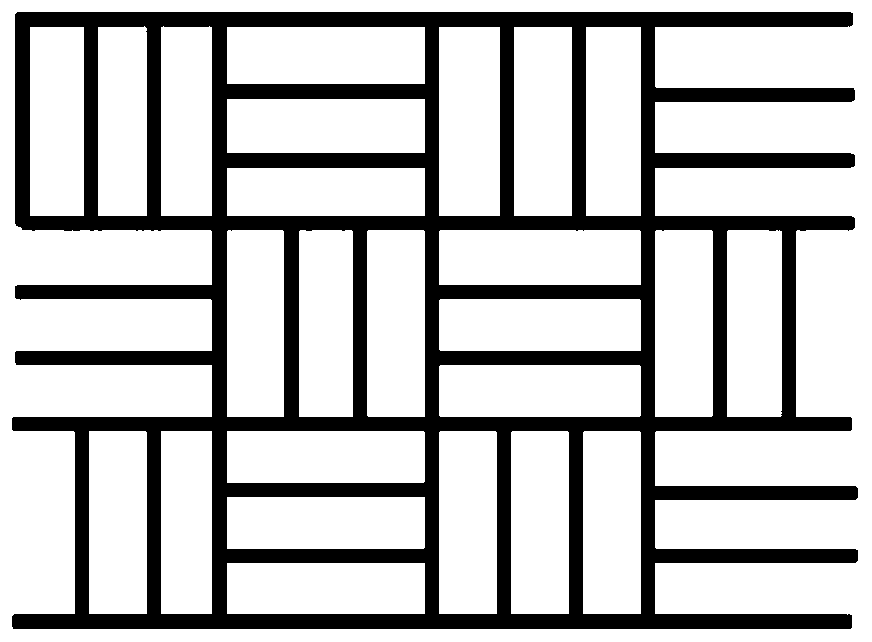

[0033] (1) Preparation of carbon fiber plain weave; carbon fiber plain weave is prepared from Japan Toho HTS40-3K carbon fiber silk, Japan Toho HTS40-3K carbon fiber silk is untwisted polypropylene long carbon fiber silk, and the preparation process is warp direction carbon fiber and weft Interweave every other strand of carbon fiber to form a plain weave structure, such as figure 2 As shown, the carbon fiber plain weave is obtained;

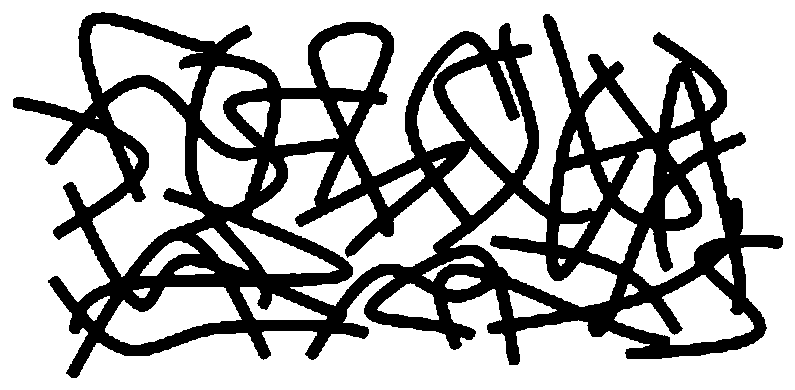

[0034] (2) Preparation of carbon fiber net tire; carbon fiber net tire adopts Japanese Toray T700SC-12000-50C untwisted polypropylene clear chopped carbon fiber to prepare, and the length of chopped carbon fiber is 60~70mm;

[0035] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com