Production method of polyester filament spunbonded needle-punched felt base

A production method and filament spinning technology, applied in the directions of melt spinning, stretch spinning, filament/thread forming, etc., can solve the problem of long process, poor elongation, low strength, etc. problems, to achieve the effects of thermal shrinkage and stability of various indicators, high molecular chain orientation, and stable molecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

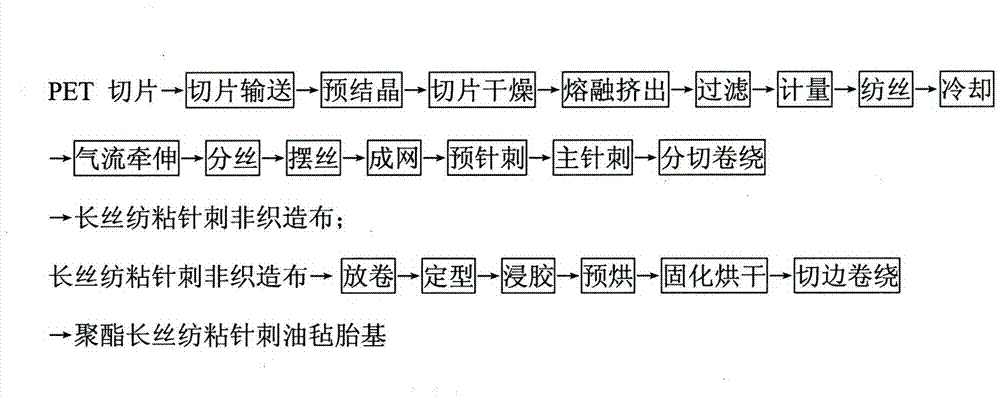

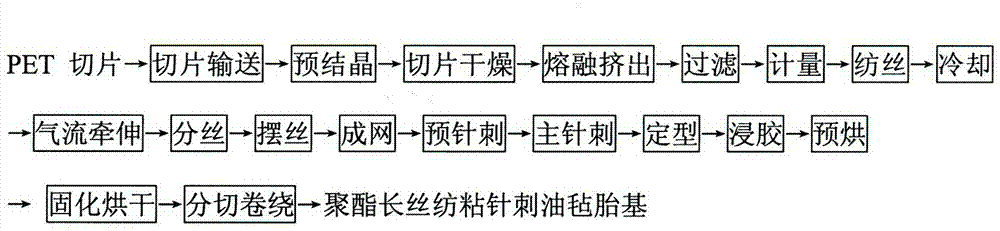

Method used

Image

Examples

Embodiment 1

[0058] Put polyester (PET) slices in a pre-crystallizer for pre-crystallization, pre-crystallization temperature: 165°C, pre-crystallization time: 20 minutes. The pre-crystallized raw material was dried, the drying temperature was 155° C., the drying time was 5 hours, and the water content of the raw material after drying was 25 ppm. A screw extruder was used for melt extrusion, and the heating temperatures of each heating zone of the screw extruder were 265°C, 276°C, 281°C, 284°C, 285°C, 285°C, and 285°C. The melt extruded by the screw extruder is filtered through a filter, and the pressure after the filter is 7.0Mpa; the filtered melt enters the spinning machine, and is sprayed into filaments from the spinneret after metering, and the fineness of the single filament is 3dpf. The initial pressure of the filament assembly: 11 Mpa, the maximum operating pressure: 25Mpa, the temperature of the heat medium in the spinning system: 288°C. The primary fiber is cooled by side blowin...

Embodiment 2

[0060] Put polyester (PET) slices in a pre-crystallizer for pre-crystallization, pre-crystallization temperature: 170°C, pre-crystallization time: 25 minutes. The pre-crystallized raw material is dried, the drying temperature is 160° C., the drying time is 5 hours, and the water content of the raw material after drying is 30 ppm. A screw extruder was used for melt extrusion, and the heating temperatures of each heating zone of the screw extruder were 265°C, 276°C, 282°C, 286°C, 288°C, 288°C, and 288°C. The melt extruded by the screw extruder is filtered through a filter, and the pressure after the filter is 8.0Mpa; the filtered melt enters the spinning machine, and after metering, it is sprayed into filaments from the spinneret, and the fineness of the single filament is 4dpf. The initial pressure of the filament assembly: 13 Mpa, the maximum working pressure: 25Mpa, the temperature of the heating medium in the spinning system: 288°C. The primary fiber is cooled by side blowi...

Embodiment 3

[0062] Put polyester (PET) slices in a pre-crystallizer for pre-crystallization, pre-crystallization temperature: 175°C, pre-crystallization time: 35 minutes. The pre-crystallized raw material is dried, the drying temperature is 165° C., the drying time is 5.5 hours, and the water content of the raw material after drying is 30 ppm. A screw extruder was used for melt extrusion, and the heating temperatures of each heating zone of the screw extruder were 275°C, 282°C, 286°C, 286°C, 292°C, 293°C, and 293°C. The melt extruded by the screw extruder is filtered through the filter, and the pressure after the filter is 9.0Mpa; the filtered melt enters the spinning machine, and is sprayed into filaments from the spinneret after metering. The initial pressure of the filament assembly: 11 Mpa, the maximum working pressure: 25Mpa, the temperature of the heat medium in the spinning system: 292°C. The primary fiber is cooled by side blowing, the temperature of the side blowing air is 21°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com