Filling cotton and preparation method thereof

A production method and technology of filling cotton, which is applied in the field of thermal insulation materials, can solve problems such as low production efficiency, loss of elasticity, and inability to use normally, and achieve the effects of increased production efficiency, labor saving, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

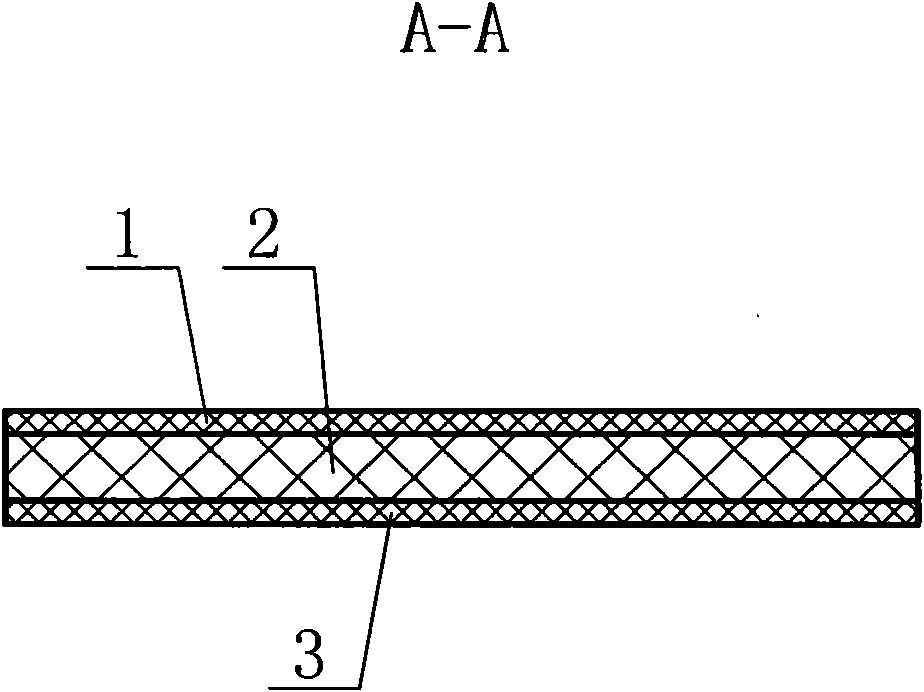

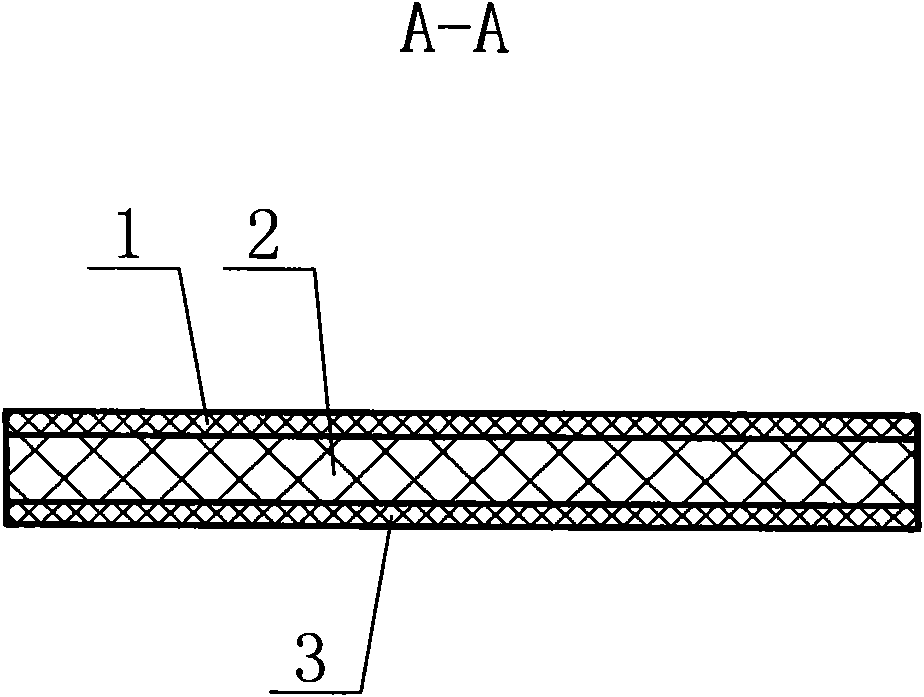

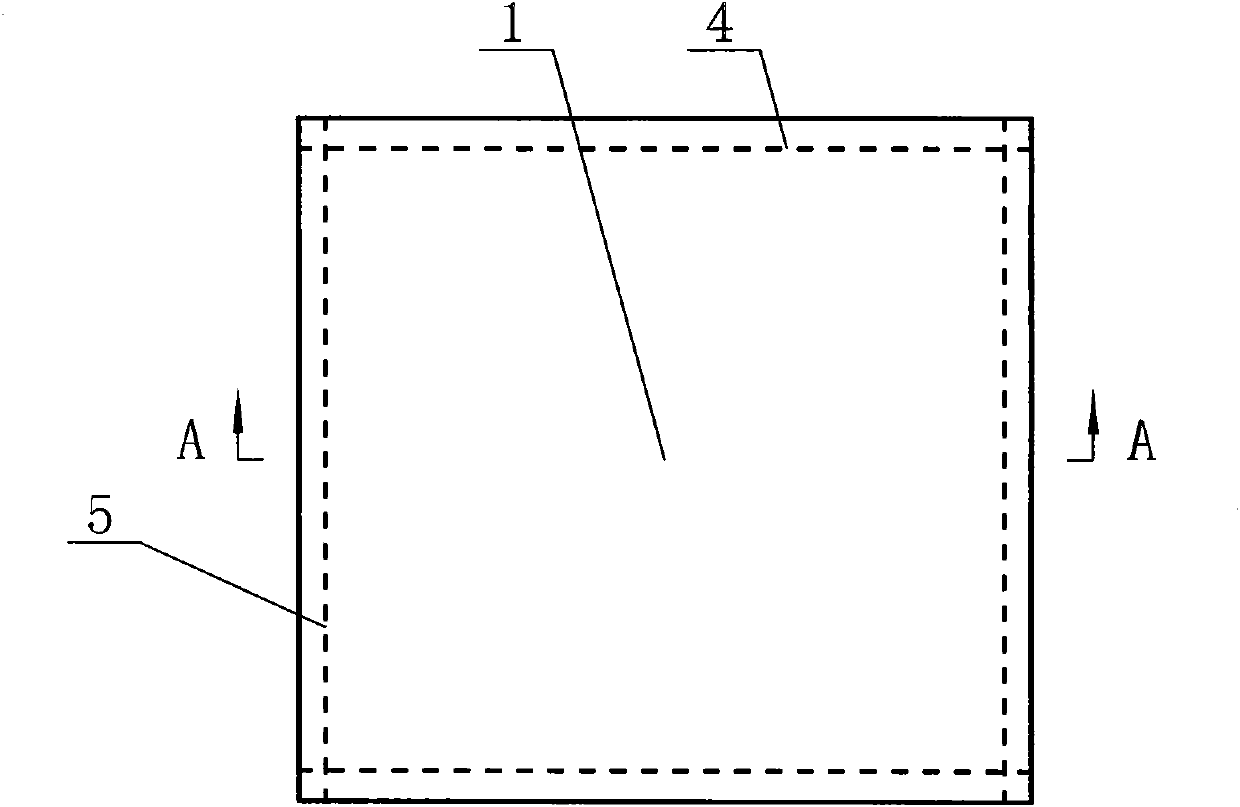

[0014] The filling cotton described in the present invention comprises an upper needle-punched surface layer 1 and a lower needle-punched surface layer 3, a fiber web layer 2 is arranged between the upper needle-punched surface layer 1 and the lower needle-punched surface layer 3, and the upper needle-punched surface layer 1. The web layer 2 and the lower needle-punched surface layer 3 are connected by a strip-shaped needle-punched belt. Among them, the upper needle-punched surface layer 1 and the lower needle-punched surface layer 3 have undergone acupuncture treatment in advance, have good tensile strength, and play a role in maintaining the shape of the filling cotton, while the fiber web layer 2 has good elasticity and softness, It can ensure the comfort of the filling cotton and meet the market demand. The strip-shaped needle-punched belt plays the role of connecting the upper needle-punched surface layer 1, the fiber mesh layer 2 and the lower needle-punched surface layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com