Needled felt surface processing agent and impregnation technology thereof

A technology of surface treatment agent and needle-punched felt, applied in the field of needle-punched felt surface treatment agent and its impregnation process, can solve the problems of difficulty in meeting the minimum requirements, easy to be corroded by acidic substances, difficulty in cleaning dust, etc. Strong effect of dust removal and self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

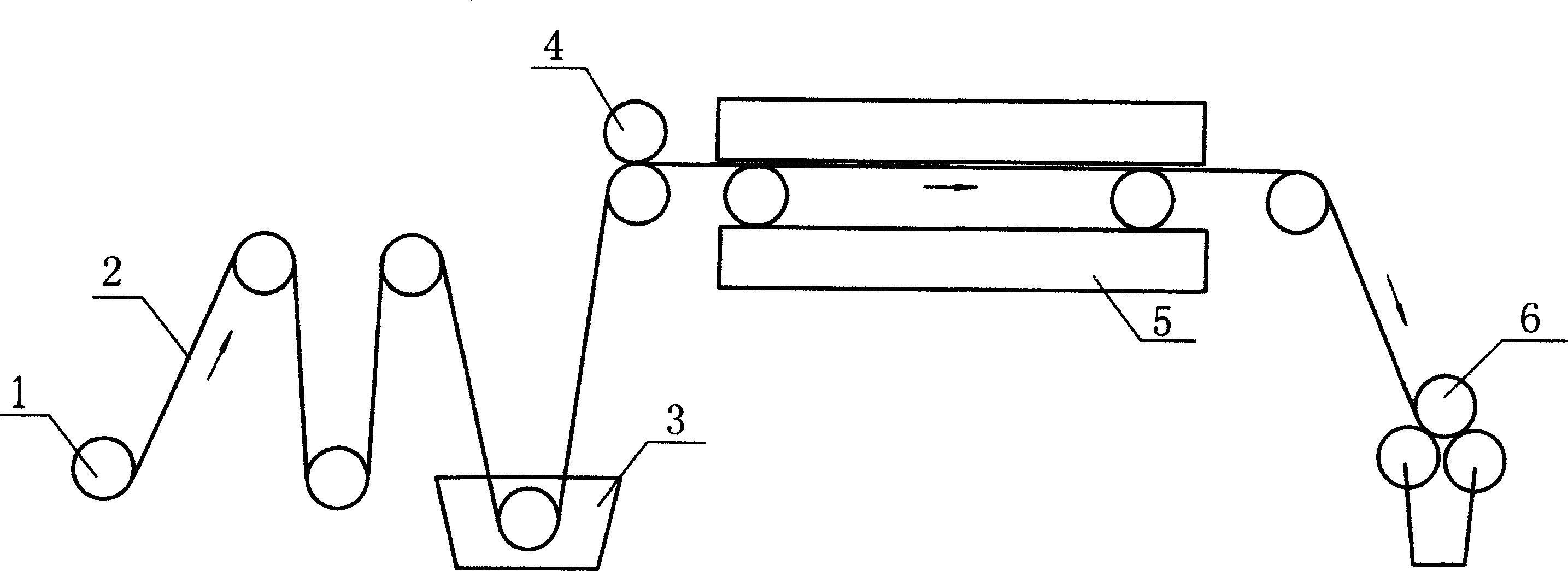

Image

Examples

Embodiment 1~9

[0028] Table 1 shows the formulations of 9 needle felt surface treatment agents selected for the embodiment of the present invention. In the header column of Table 1:

[0029] "PTFE emulsion" means a fluoropolymer emulsion (solid content 60%, commercially available). The molecular weight of polytetrafluoroethylene used in fluoropolymer emulsion ranges from 2,000,000 to 4,000,000;

[0030] "A6" represents a commercially available polyurethane aqueous solution (solid content: 35%, commercially available).

[0031] "285 silicone oil emulsion" means commercially available 285 benzyl silicone oil emulsion (solid content 35%, commercially available).

[0032] "TiO 2 "Represents that the nanomaterial used is nanoscale titanium oxide, and the particle size is 50-100 nanometers (commercially available).

[0033] Select commercially available KH-570, the chemical name is γ-methacryloxypropyltrimethoxysilane, and the molecular formula is CH 2 =CCH 3 COCH 2 CH 2 CH 2 Si(OCH 2 CH...

Embodiment 10

[0049] In the present embodiment, "FEP emulsion" adopts polytetrafluoroethylene hexafluoroethylene copolymer emulsion, (solid content 50%), and this component weight percentage is constant; "A6" adopts commercially available polyacrylate (solid content 38%), the component weight percent is constant; adopt commercially available nanometer zinc oxide (ZnO) to replace the titanium oxide (TiO 2 ), the particle size is 50-100 nanometers, and the component weight percentage is constant. The preparation process and dipping process of other ingredients and formula are the same as those in Examples 1-9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com