Environmentally friendly differential fiber non-woven automotive interior trim material and preparation method thereof

A differentiated and environmentally friendly technology, applied in the direction of non-woven fabrics, fiber types, fiber treatment, etc., can solve the problems of difficult production and weak new product development capabilities, and achieve the prevention of surface color difference and uneven color, excellent flame retardancy Effect, effect to prevent expansion of flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

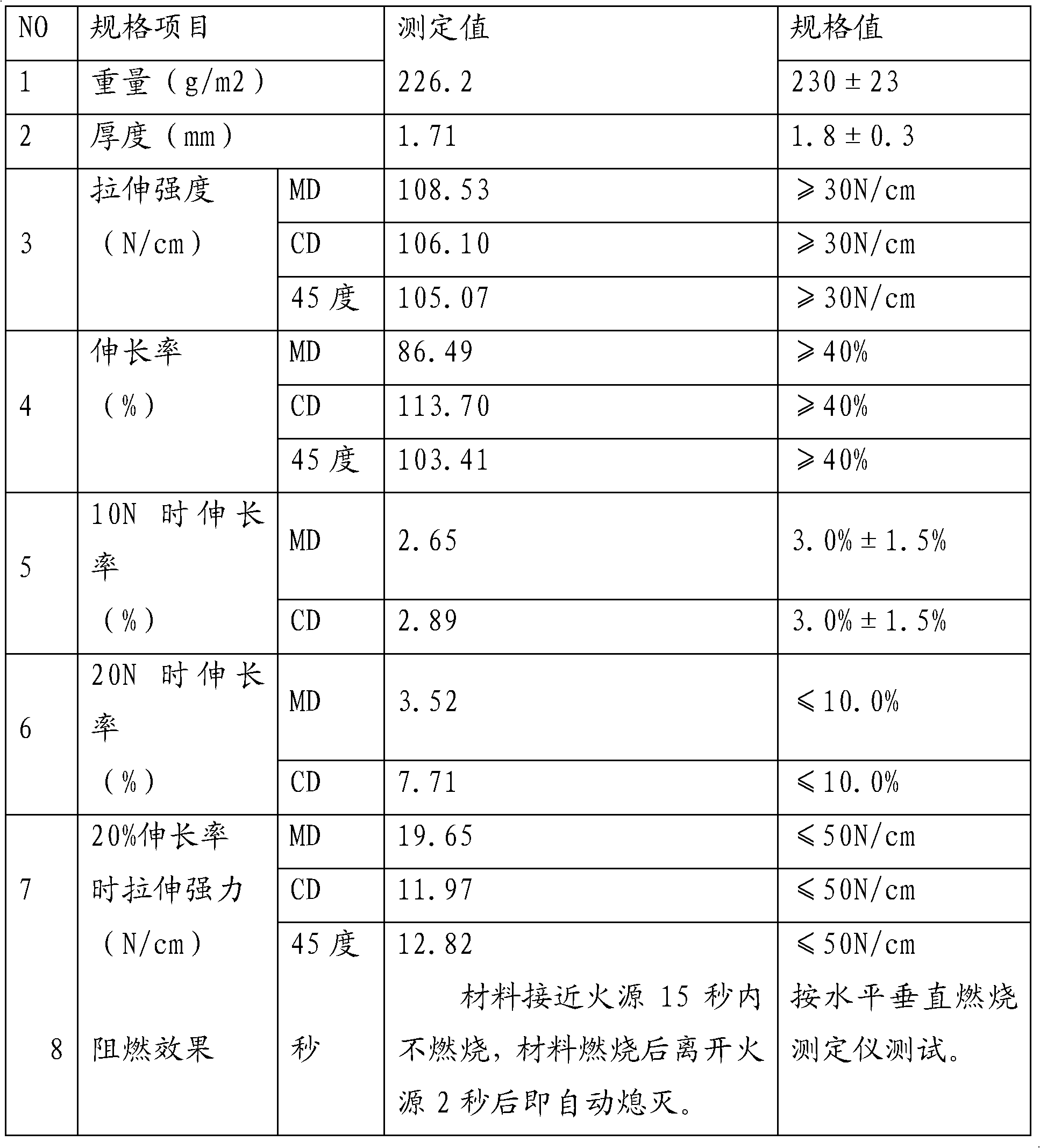

Embodiment 1

[0027] Environmental-friendly differentiated fiber non-woven automotive interior materials are produced by the following steps: using environmentally-friendly colored flame-retardant polyester staple fibers as raw materials, opening and weighing fiber feeding, rough opening, fiber mixing, fine opening, fiber Carding and cross-lapping, the main felting needle is 42 # The needles are processed by five acupuncture machines. The draft ratios from front to back are 33%, 28%, 10%, 3%, and 3%, respectively, and the corresponding needle density is 85N / cm 2 、180N / cm 2 、200N / cm 2 、100N / cm 2 、80N / cm 2 . The corresponding needle depths are 9mm, 8mm, 8mm, 7.5mm, and 6.6mm respectively; the speed of the main cylinder is 1000m / min, the speed of the small cylinder is 360m / min, and the speed of the upper and lower doffers is controlled at 60m / min and 62m respectively / min, the speed of the upper and lower coagulation is controlled at 35m / min and 38m / min respectively. After the needle-pun...

Embodiment 2

[0033] Environmental-friendly differentiated fiber non-woven automotive interior materials are produced by the following steps: using environmentally-friendly colored flame-retardant polyester staple fibers as raw materials, opening and weighing fiber feeding, rough opening, fiber mixing, fine opening, fiber Carding and cross-lapping, the main felting needle is 42 # The needles are processed by five acupuncture machines. The draft ratios from front to back are 30%, 31%, 9.5%, 4%, and 1%, respectively, and the corresponding needle density is 80N / cm 2 、170N / cm 2 、190N / cm 2 、95N / cm 2 、75N / cm 2 , the corresponding needle depths are 8.5mm, 7.5mm, 7.2mm, 7.0mm, 6.0mm; the speed of the main cylinder is 950m / min, the speed of the small cylinder is 320m / min, and the speed of the upper and lower doffers is controlled at 58m respectively / min, 60m / min, the speed of the upper and lower coagulation rollers is controlled at 33m / min, 36m / min respectively. After the needle-punched gray f...

Embodiment 3

[0036] Environmental-friendly differentiated fiber non-woven automotive interior materials are produced by the following steps: using environmentally-friendly colored flame-retardant polyester staple fibers as raw materials, opening and weighing fiber feeding, rough opening, fiber mixing, fine opening, fiber Carding and cross-lapping, the main felting needle is 42 # The needles are processed by five acupuncture machines. The draft ratios from front to back are 36%, 25%, 10.5%, 2%, and 3%, respectively, and the corresponding needle densities are 90N / cm 2 、190N / cm 2 、210N / cm 2 、105N / cm 2 、85N / cm 2 , the corresponding needle depths are 10.0mm, 9.0mm, 8.8mm, 8.5mm, 7.2mm respectively. The speed of the main cylinder is 1050m / min, the speed of the small cylinder is 400m / min, the speed of the upper and lower doffers is controlled at 62m / min and 64m / min respectively, and the speed of the upper and lower coagulation rollers is controlled at 37m / min and 40m respectively / min. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com