Preparation method of metal-type C/C composite material carbon slide strips

A technology of composite materials and metal molding, which is applied in the field of material preparation for electric locomotives, can solve the problems of high process cost and high resistivity of metal-type carbon fiber skateboards, and achieve the effects of low process cost, convenient industrial production, and lower resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

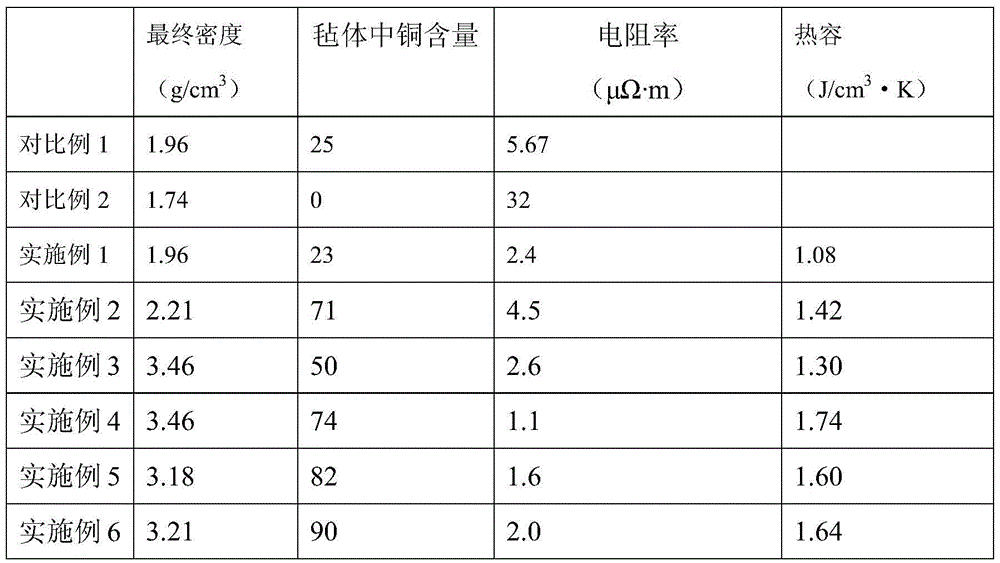

Embodiment 1

[0031] The diameter of copper wire is 0.12mm, the number of mesh is 40 mesh, the mass content is 23% red copper mesh, graphite powder (mass percentage content is 10%), carbon fiber, and the density is 0.94g / cm 3 The 2.5D carbon fiber needle-punched integral felt was prepared by chemical vapor infiltration process with a density of 1.72g / cm 3 The C / C composite material with a density of 1.96g / cm was prepared after two resin impregnation-carbonization processes 3 C / C composite materials.

[0032] The C / C pantograph slider in this example is mainly prepared through the following steps:

[0033] (1) At first, the PAN type T700 (12K) carbon fiber produced by Japan's Toray Company (Toray) is used to make the net tire and no weft cloth, and the single layer 0 ° no weft cloth, net tire layer, graphite powder (particle size is 100 microns), red copper mesh, single layer 90° no-weft cloth, net tire layer, graphite powder (100 microns in particle size), copper mesh, single-layer 0° no ...

Embodiment 2

[0037] The density is 1.25g / cm 3 The 2.5D carbon fiber needle-punched integral felt is a prefabricated body, wherein the prefabricated body contains copper powder, the copper powder is -200 mesh electrolytic red copper powder, and the mass content is 71%; the mass percentage content of graphite powder is 5%. The density is 2.24g / cm3 prepared by chemical vapor infiltration process 3 The C / C composite material with a density of 2.47g / cm3 was prepared through three resin impregnation-carbonization processes. 3 C / C composite materials.

[0038] The C / C pantograph slider in this example is mainly prepared through the following steps:

[0039] (1) First, the PAN type T700 (12K) carbon fiber produced by Japan Toray Company (Toray) is used to make a mesh tire and a weft-free cloth. Single-layer 0° non-weft cloth, mesh tire layer, graphite powder (particle size is 150 microns), copper powder (particle size is 75 microns), single-layer 90° non-weft cloth, net tire layer, graphite pow...

Embodiment 3

[0043] The density is 0.89g / cm 3 The 2.5D carbon fiber needle-punched integral felt is a prefabricated body, wherein the prefabricated body contains brass wires, the diameter of the short brass wires is 0.2 mm, the length is 5 mm, the mass content is 50%, and the mass percentage of graphite powder is The content is 2%; the density is 1.92g / cm3 prepared by chemical vapor infiltration process 3 The C / C composite material with a density of 2.21g / cm3 was prepared through three resin impregnation-carbonization processes. 3 C / C composite materials.

[0044] The C / C pantograph slider in this example is mainly prepared through the following steps:

[0045] (1) At first, the PAN type T700 (12K) carbon fiber produced by Japan's Toray Company (Toray) is used to make the net tire and no weft cloth, and the single layer 0 ° no weft cloth, net tire layer, graphite powder (particle size is 38 microns), short copper wire (0.1mm in diameter, 20mm in length), single-layer 90° no-weft cloth, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com