Fire retardant cotton nonwoven fabrics and manufacture method thereof

A technology of non-woven fabrics and flame-retardant cotton, applied in the field of flame-retardant cotton, can solve the problems of flame-retardant fibers that are difficult to meet the use requirements, melt dripping, and unsuitable applications, so as to improve application performance and safety performance, and increase added value , good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

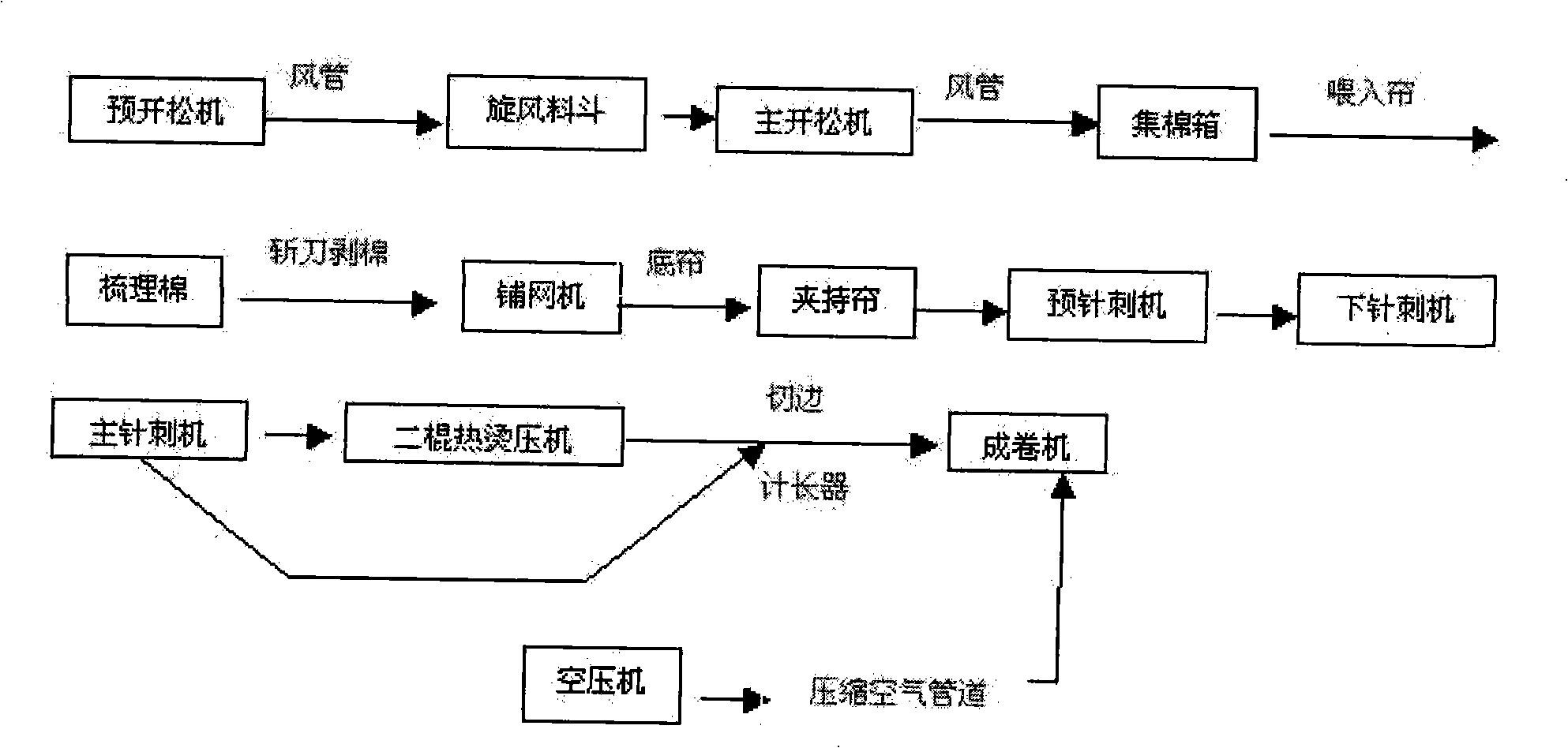

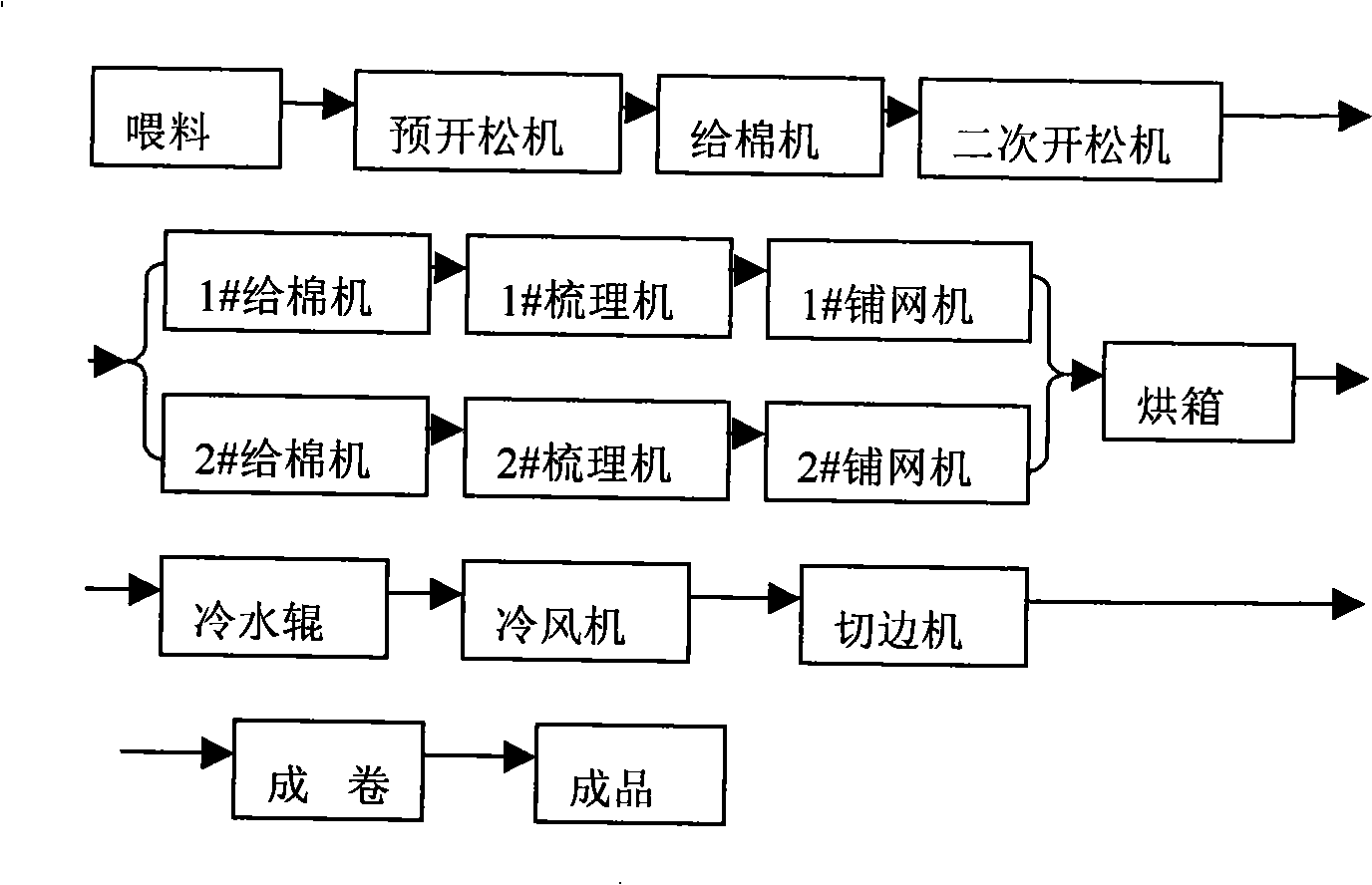

[0056] The specific features and technical means of the present invention will be further described below in conjunction with the accompanying drawings, and the positive effects of the present invention will be further described through specific implementation methods.

[0057] The flame-retardant cotton flame-retardant cotton non-woven fabric provided by the present invention includes anti-fcell and polyester / polyester composite hot-melt short fibers, wherein the weight percentage of anti-fell fiber is 70% to 90% %, and the rest are polyester / polyester composite hot-melt short fibers; the above two fibers are composited and / or interpenetrated to form a non-woven fabric.

[0058] Specifically, the proportion by weight of the Anspun flame-retardant fiber is 75%±5%, and the polyester / polyester composite hot-melt staple fiber is 25%±5%.

[0059] The specific production method of the flame-retardant cotton non-woven fabric is:

[0060] A. Mix the two raw materials of Anti-fcell a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com