Heat accumulation type block-shaped oil shale pyrolysis treatment system and method

A regenerative, oil shale technology, used in the petroleum industry, special forms of dry distillation, direct heating dry distillation, etc., can solve the problems of small single furnace scale, complex process, low oil and gas yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

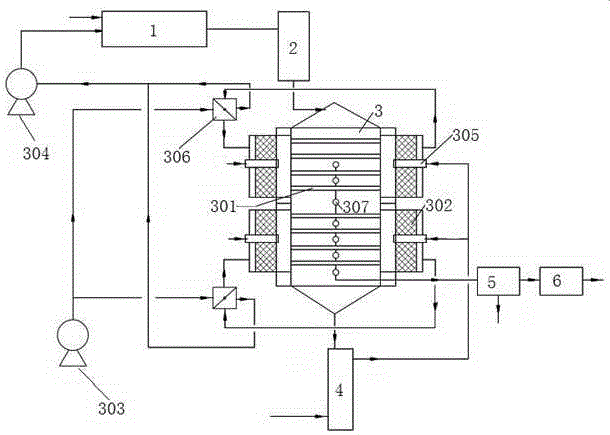

Image

Examples

Embodiment 1

[0066] The particle size of Fushun oil shale is 6-30mm, and the residence time is 60 minutes when entering the furnace. The control temperature of the radiant tube is shown in Table 2, the material balance is shown in Table 3, and the pyrolysis gas composition and calorific value are shown in Table 4.

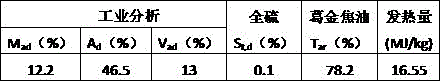

[0067] Table 1: Australian lignite analysis data

[0068]

[0069] Table 2: Process operating parameters

[0070] Serial number parameter name Parameter value 1 Wall temperature of a radiant tube650℃ 2 Two-layer radiant tube wall temperature600℃ 3 Three-layer radiant tube wall temperature550℃ 4 Reversing valve setting time60s 5 Exhaust temperature of a layer of radiant tube180℃ 6 Two-layer radiant tube wall temperature160℃ 7 Three-layer radiant tube wall temperature140℃

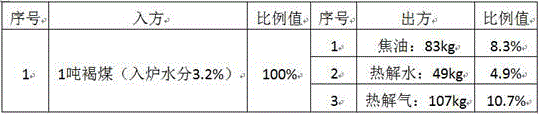

[0071] Table 3: Material balance sheet

[0072]

[0073] Table 4: Pyrolysis gas composition table

[0074] Serial number Gas composition and composition Result vol% 1CH 4

[0075] In the description of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com