Photocatalytic sealed CO2 laser tube

A carbon dioxide and laser tube technology, applied in lasers, laser components, laser components, etc., can solve problems such as changes in working gas composition and pollution of total reflection mirrors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

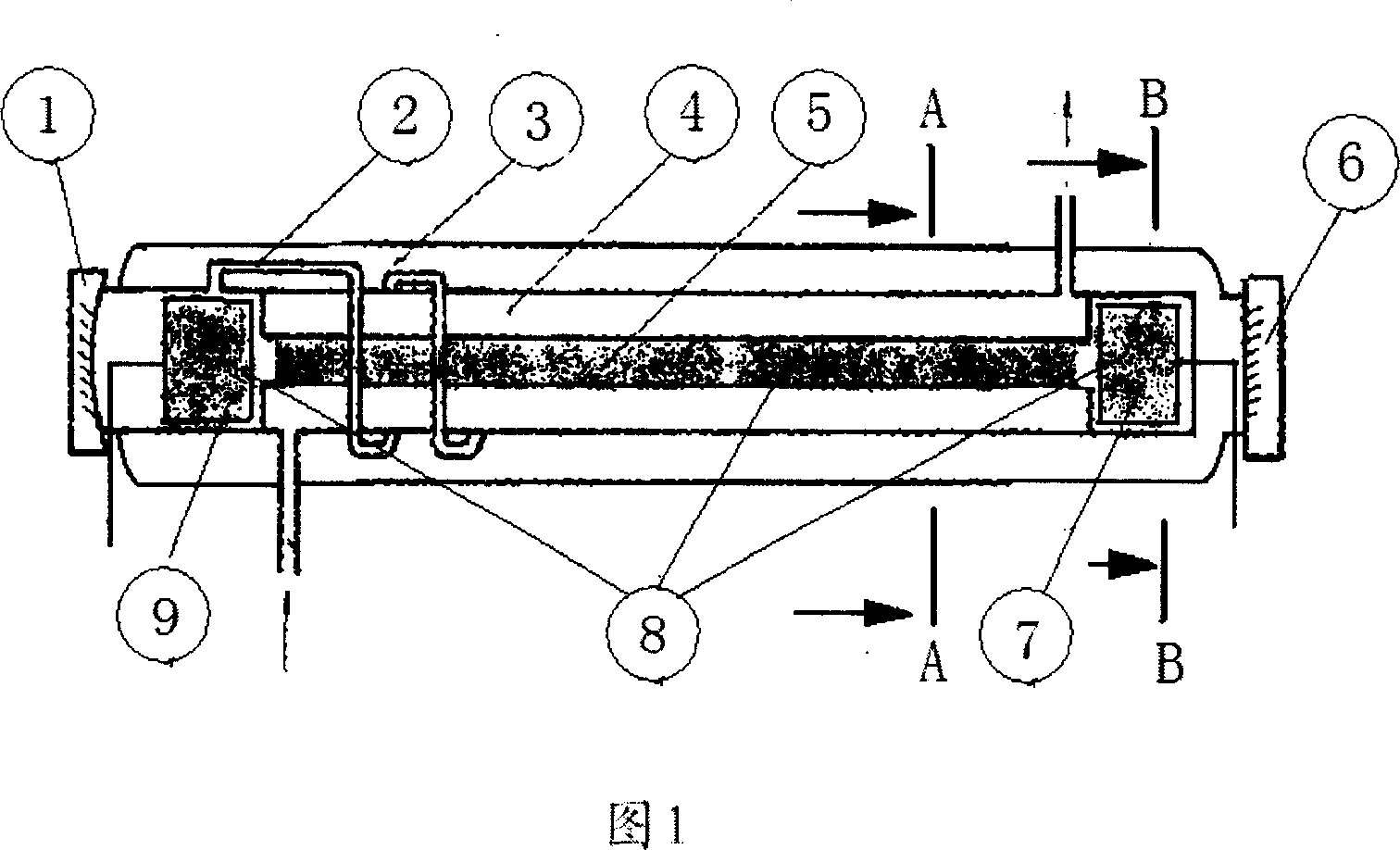

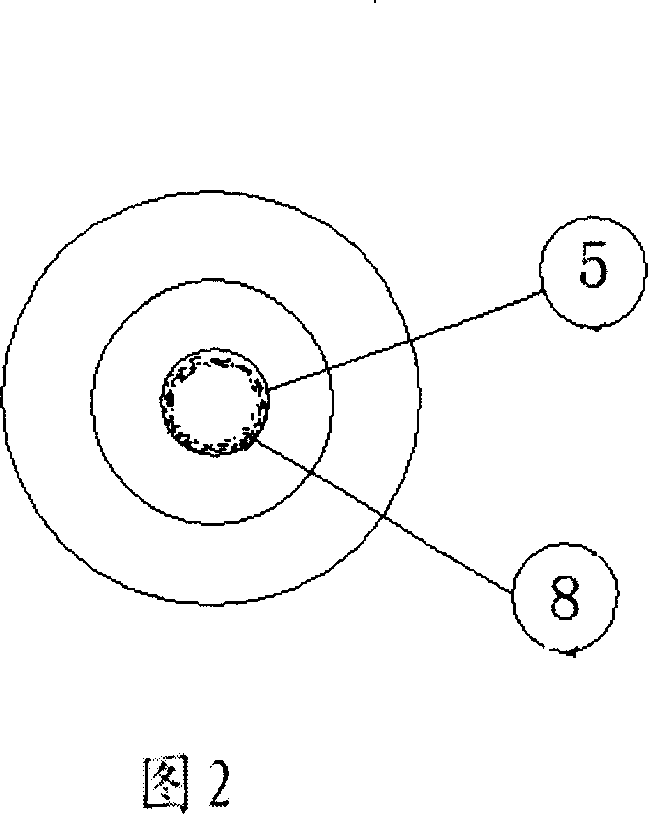

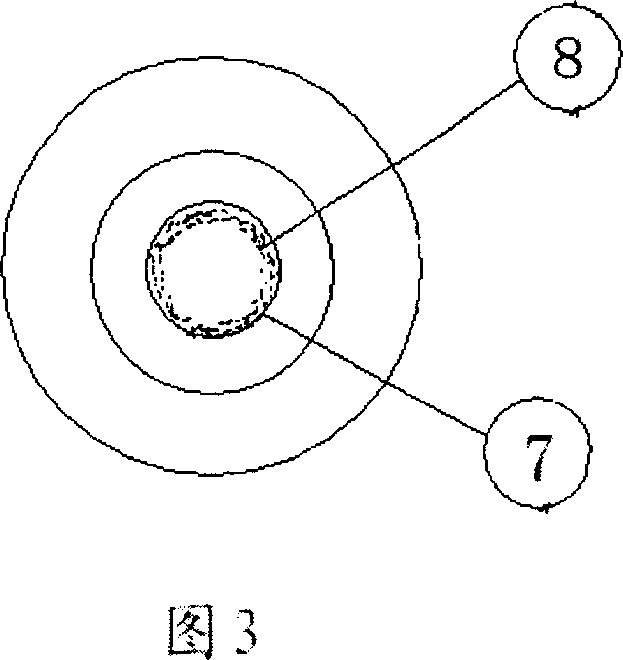

[0013] In Figure 1, the photocatalyst-enclosed carbon dioxide laser tube includes a discharge tube ⑤, a gas storage sleeve ③, a water-cooled tube ④, an output mirror ⑥, a gas return pipe ②, a gold-plated total reflection mirror ①, a cathode ⑦, and an anode ⑨. The discharge tube ⑤ and the water-cooled tube ④ are placed in the gas storage sleeve ③, the water-cooled tube ④ is set on the discharge tube ⑤, the cathode ⑦ and the anode ⑨ are placed at the two ends of the discharge tube ⑤ coaxially with the discharge tube ⑤, and the cathode ⑦ 1. The anode ⑨ is rolled into a cylindrical shape by a 0.1mm metal silver sheet, the inner wall is coated with a nano-titanium dioxide photocatalyst ⑧, and placed at both ends of the discharge tube ⑤ whose inner wall is also coated with a nano-titanium dioxide photocatalyst ⑧.

[0014] Manufacturing method:

[0015] The manufacture method of above-mentioned coated nano-titanium dioxide photocatalyst 8. is as follows: get tetra-n-butyl titanate (C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com