Meshing method for finite element model of pile foundation spiral buried pipe heat exchanger

A meshing, finite element technology, used in geometric CAD, design optimization/simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] This embodiment proposes a grid division method for a finite element model of a pile foundation spiral buried pipe heat exchanger in a fan-shaped soil area. The grid division method specifically includes the following steps:

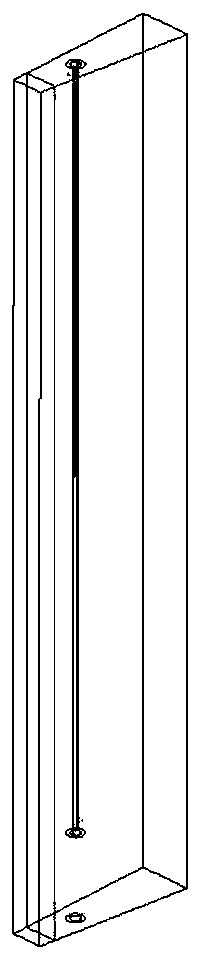

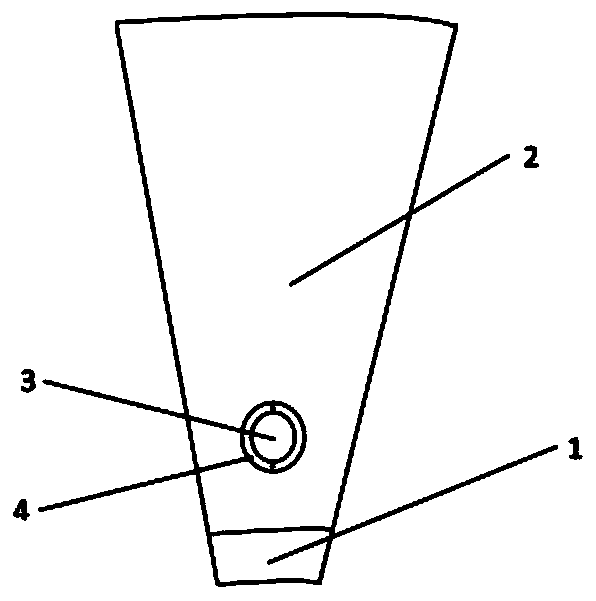

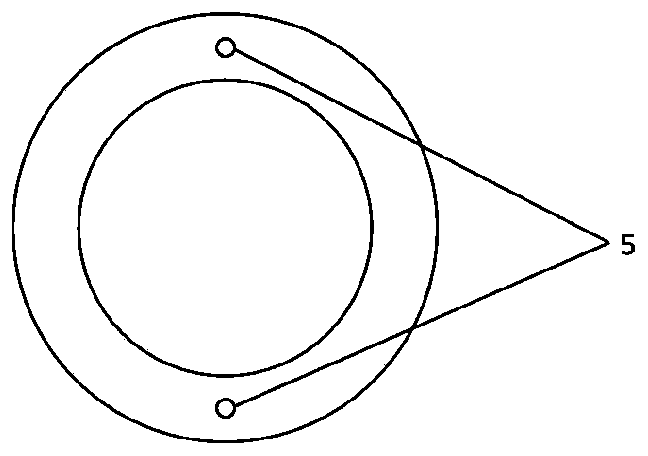

[0034] S1. Establish the finite element model of the pile foundation spiral buried tube heat exchanger in the fan-shaped soil area

[0035] The 3D modeling of the finite element model of the pile foundation buried tube heat exchanger in the fan-shaped soil area is carried out by using the DesignModeler software of ANSYS. Among them, the depth of soil area is 50m; the depth of pile foundation is 45m, the radius of pile foundation is 0.5m; the depth of spiral pipe is 44m, the radius of coil p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com