Transition liquid phase diffusion bonding method for additive manufacturing stainless steel and zirconium alloy

A technology of diffusion connection and additive manufacturing, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of uneven atomic diffusion, lower joint performance, and long preparation cycle, so as to facilitate interface bonding and reduce residual stress , the effect of reducing the number of generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The transition liquid phase diffusion connection method of additively manufactured stainless steel and zirconium alloy of the present invention comprises the following steps:

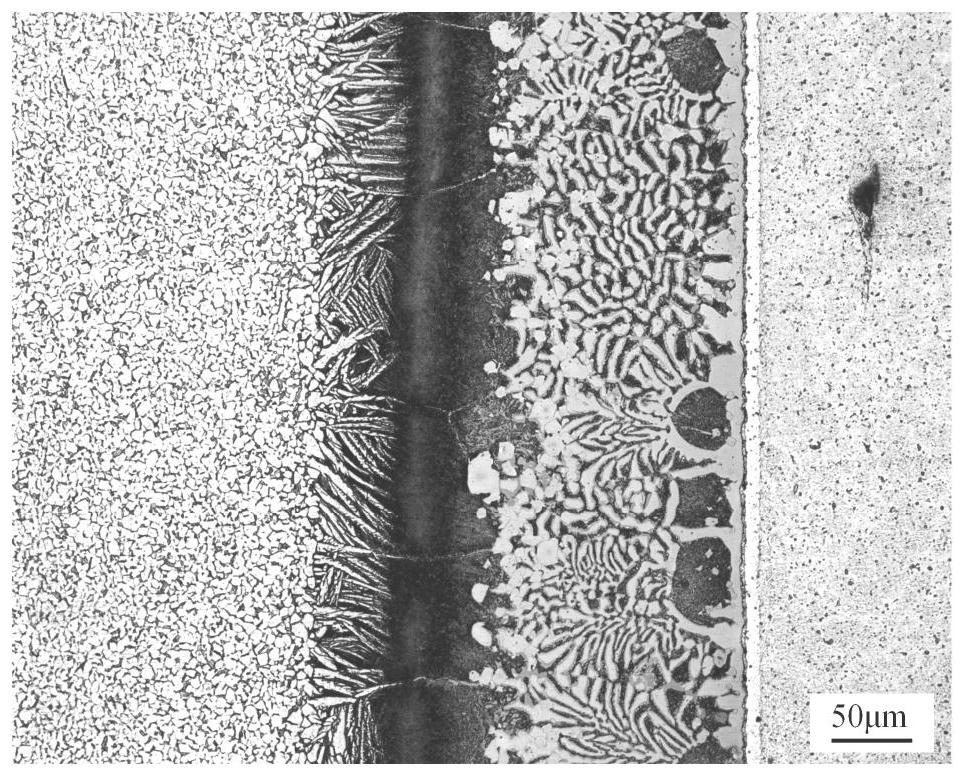

[0030] (1) 17-4PH stainless steel is prepared by atomic diffusion additive manufacturing process. The additively manufactured 17-4PH stainless steel and R60702 zirconium alloy test plate are wire-cut, and the additively manufactured 17-4PH stainless steel is cut into a size of 10mm×10mm×5mm , R60702 zirconium alloy is cut into a size of 10mm × 10mm × 5mm, and the size of the surface to be connected is 10mm × 10mm;

[0031] (2) Use different types of sandpaper from coarse to fine to grind the surfaces to be joined of the additively manufactured 17-4PH stainless steel and R60702 zirconium alloy samples to remove oxide scale and oil; put the polished samples into acetone reagent Perform ultrasonic cleaning to remove oil stains for 5 min; then put the sample into absolute ethanol for ultrasonic clean...

Embodiment 2

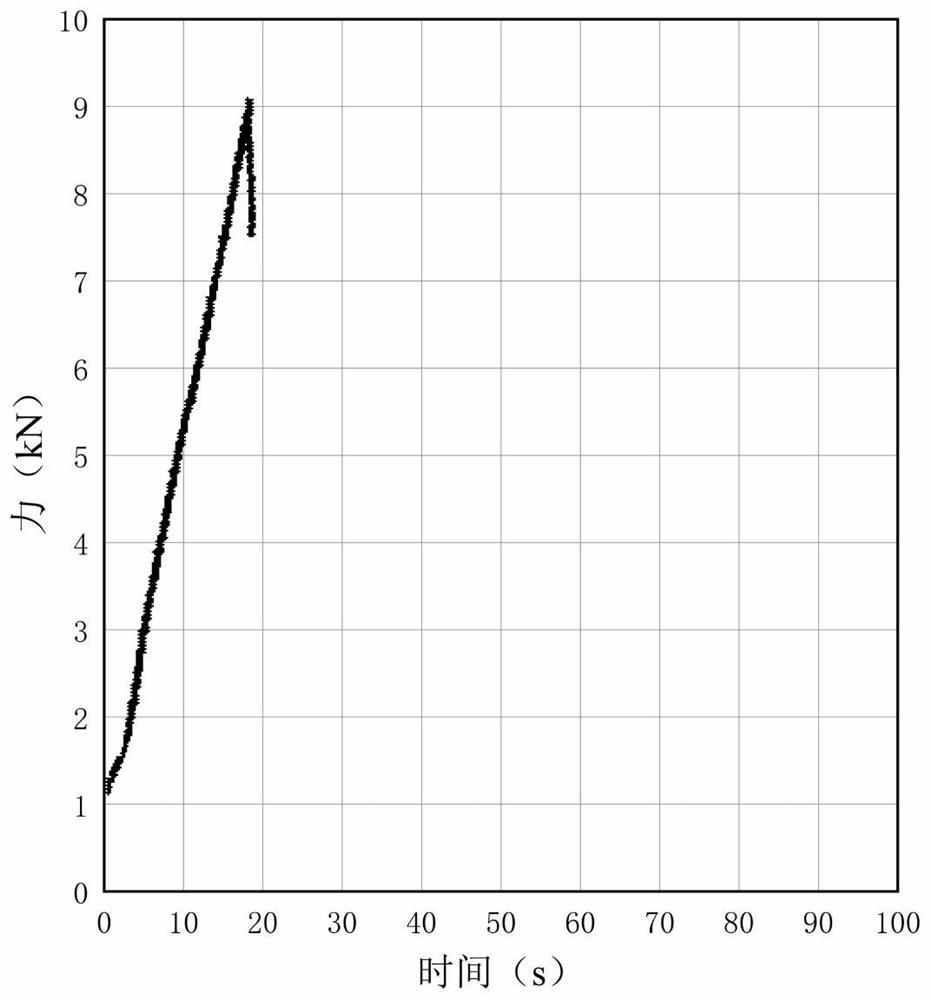

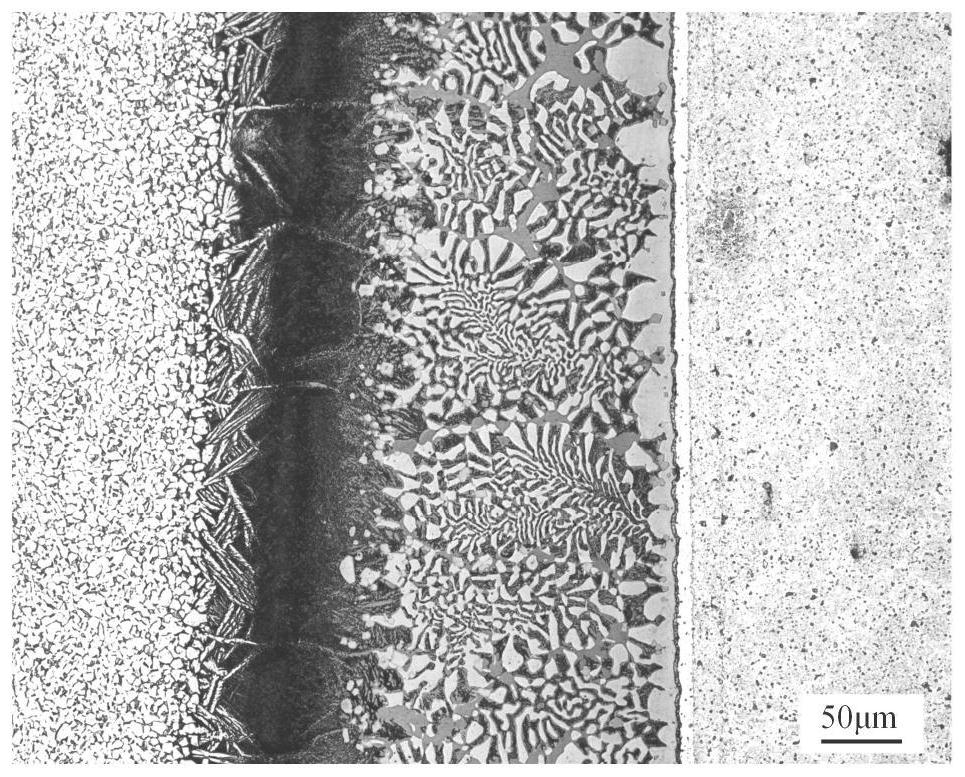

[0040] The transition liquid phase diffusion connection method of additively manufactured stainless steel and zirconium alloy of the present invention comprises the following steps:

[0041] (1) 316L stainless steel is prepared by selective laser melting process. The additively manufactured 316L stainless steel and R60705 zirconium alloy test plate are cut by wire cutting, and the additively manufactured 316L stainless steel is cut to a size of 10mm×10mm×5mm, and the R60705 zirconium alloy is cut to size It is 10mm×10mm×5mm, and the size of the surface to be connected is 10mm×10mm;

[0042] (2) Grind the surfaces to be joined of the 316L stainless steel and R60705 zirconium alloy samples by adding different types of sandpaper from coarse to fine to remove oxide scale and oil stains. Put the polished sample into acetone reagent for ultrasonic cleaning to remove oil stains for 10 minutes; then put the sample into absolute ethanol for ultrasonic cleaning for 10 minutes; then, dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com