Mesh division method for multilayer multi-pass welding finite element model of header tube socket

A multi-layer multi-pass welding and grid division technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving the grid generation time and reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

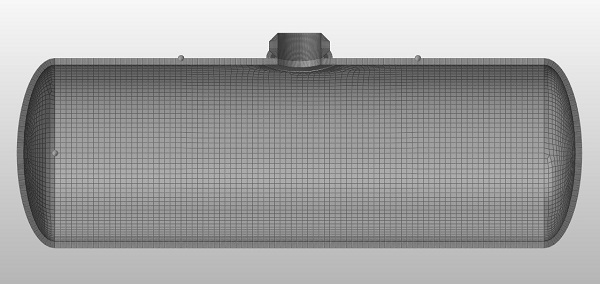

[0024] This embodiment proposes a grid division method for the multi-layer multi-pass welded finite element model of the header pipe seat. The grid division method specifically includes the following steps:

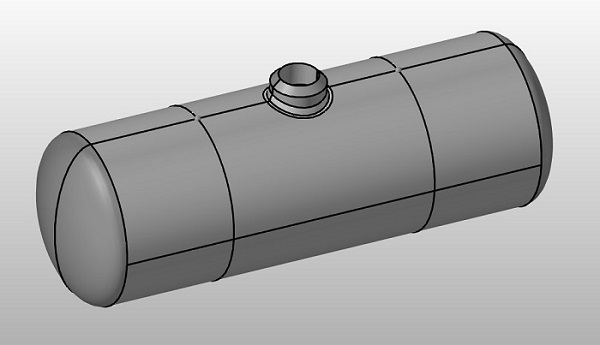

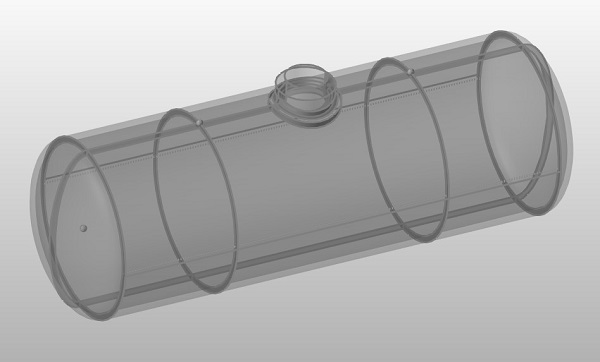

[0025] S1. Establish the finite element model of the saddle-shaped multi-layer multi-pass welding of the header pipe seat; use Solidworks software to carry out the three-dimensional modeling of the finite element model of the multi-layer multi-pass welding of the header pipe seat. Among them, the size of the header is selected as φ350×12×1000mm, the size of the pipe seat is DN80×15mm, there is no blunt edge, no weld gap, the groove angle is 42°, the weld shape is a saddle-shaped space curve, and the weld is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com