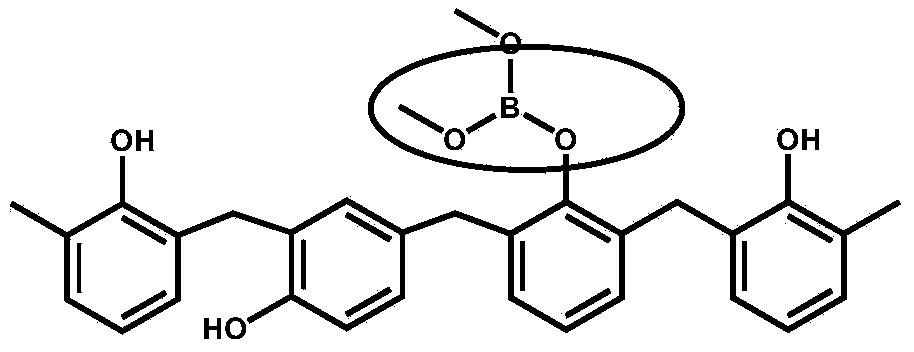

Technique for synthesizing boron-containing thermoplastic phenol formaldehyde resin by solvothermal process

A phenolic resin and solvothermal technology, applied in the field of synthesizing phenolic resin, can solve the problems of increasing the viscosity of the system, being difficult to form, restricting the production and application of boron-containing phenolic resin, and achieving the effects of good thermal stability and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 100g of random thermoplastic phenolic resin, 10g of 4-hydroxymethylbenzeneboronic acid and 1g of oxalic acid are added into a solvothermal reactor with a volume of 500mL, and then 100g of solvent is added to the solvent reactor, and after stirring, a milky white suspension is obtained; The thermal reaction kettle was sealed, and the reaction product was obtained after being kept at 140° C. for 3 hours. Naturally cool the solvothermal reactor to reduce pressure, and then open the reactor after cooling to room temperature to obtain a viscous and transparent liquid, which is light yellow in color; dry the above-mentioned light yellow viscous liquid at 70°C and -0.08MPa for 4 hours Finally, a white block is obtained, and a boron-containing thermoplastic phenolic resin is obtained after grinding; wherein, the solvent is formed by mixing absolute ethanol and deionized water with a mass ratio of 1:0.11.

[0035] The content of free phenol in the synthesized boron-containing th...

Embodiment 2

[0037] Add 100g of high-ortho thermoplastic phenolic resin, 20g of 2-hydroxymethylphenylboronic acid monoester and 2g of oxalic acid into a solvothermal reaction kettle with a volume of 500mL, then add 100g of solvent to the solvent reaction kettle, and obtain a milky white suspension after stirring liquid; seal the solvothermal reaction kettle, and keep the temperature at 160°C for 2 hours to obtain the reaction product. Naturally cool the solvothermal reactor to reduce pressure, and then open the reactor after cooling to room temperature to obtain a viscous and transparent liquid, which is light yellow in color; dry the above-mentioned light yellow viscous liquid at 80°C and -0.08MPa for 1 hour Finally, a white block is obtained, and a boron-containing thermoplastic phenolic resin is obtained after grinding; wherein, the solvent is composed of absolute ethanol and deionized water with a mass ratio of 1:0.25.

[0038] The content of free phenol in the synthesized boron-contai...

Embodiment 3

[0040] Add 100g of bisphenol A type thermoplastic phenolic resin, 5g of 5-hydroxymethylpyridine-3-boronic acid and 0.5g of oxalic acid into a solvothermal reactor with a volume of 500mL, then add 60g of solvent to the solvent reactor, and after stirring A milky white suspension was obtained; the solvothermal reaction kettle was sealed and kept at 120° C. for 6 hours to obtain a reaction product. Naturally cool the solvothermal reactor to reduce pressure, and then open the reactor after cooling to room temperature to obtain a viscous and transparent liquid, which is light yellow; dry the above-mentioned light yellow viscous liquid at 60°C and -0.08MPa for 6 hours Finally, a white block is obtained, and a boron-containing thermoplastic phenolic resin is obtained after grinding; wherein, the solvent is anhydrous ethanol and deionized water with a mass ratio of 1:0.7.

[0041] The content of free bisphenol A in the synthesized boron-containing thermoplastic phenolic resin is 0.27%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com