Multi-station numerical control lathe

A numerical control lathe and multi-station technology, applied in the field of numerical control lathes, can solve the problems of difficult control of the starting position of processing, unfavorable adjustment of the lateral position, damage to the structure of the machine tool, etc., achieving the effect of easy operation of the structure, speeding up the maintenance rate, and optimizing the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

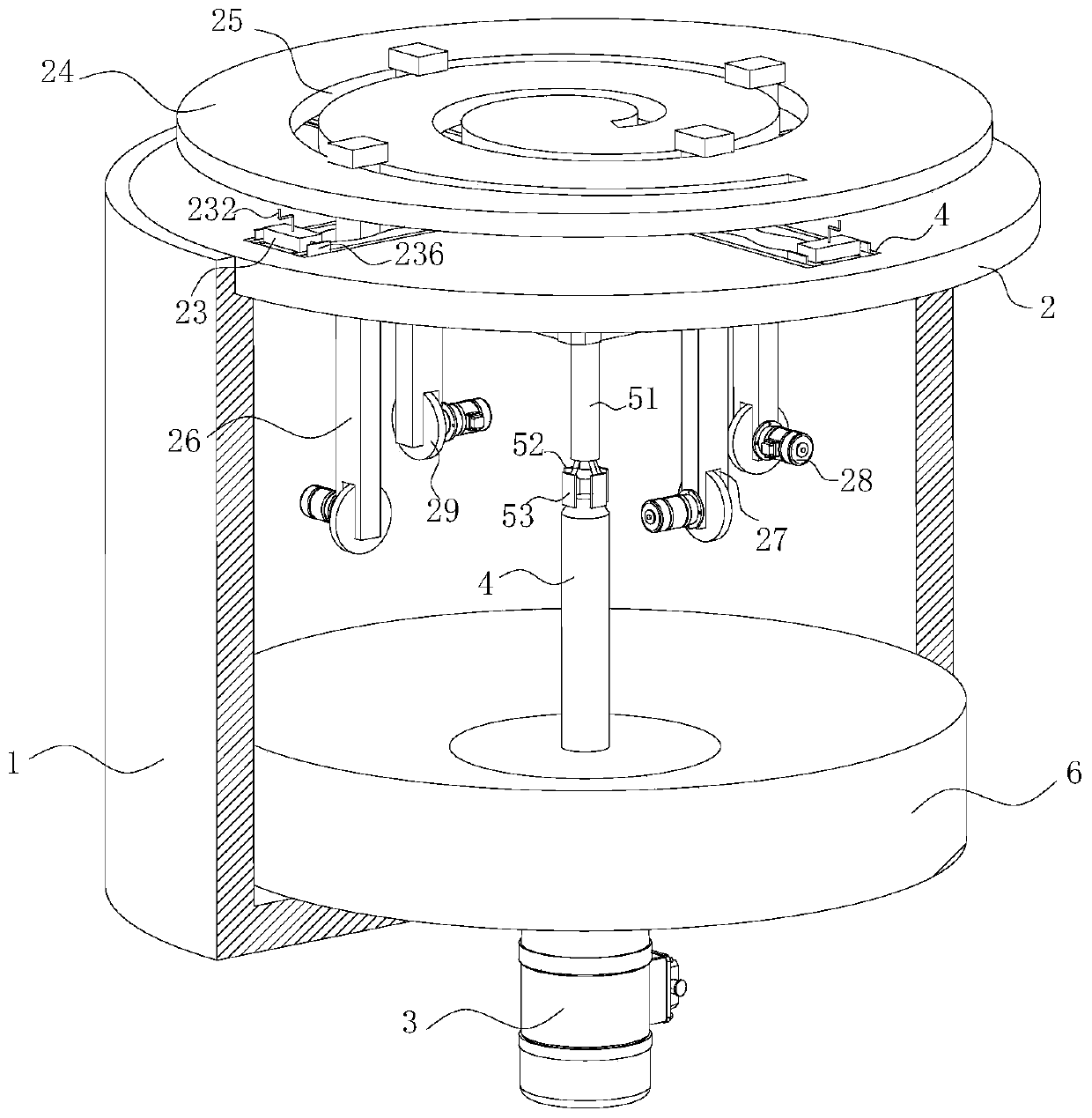

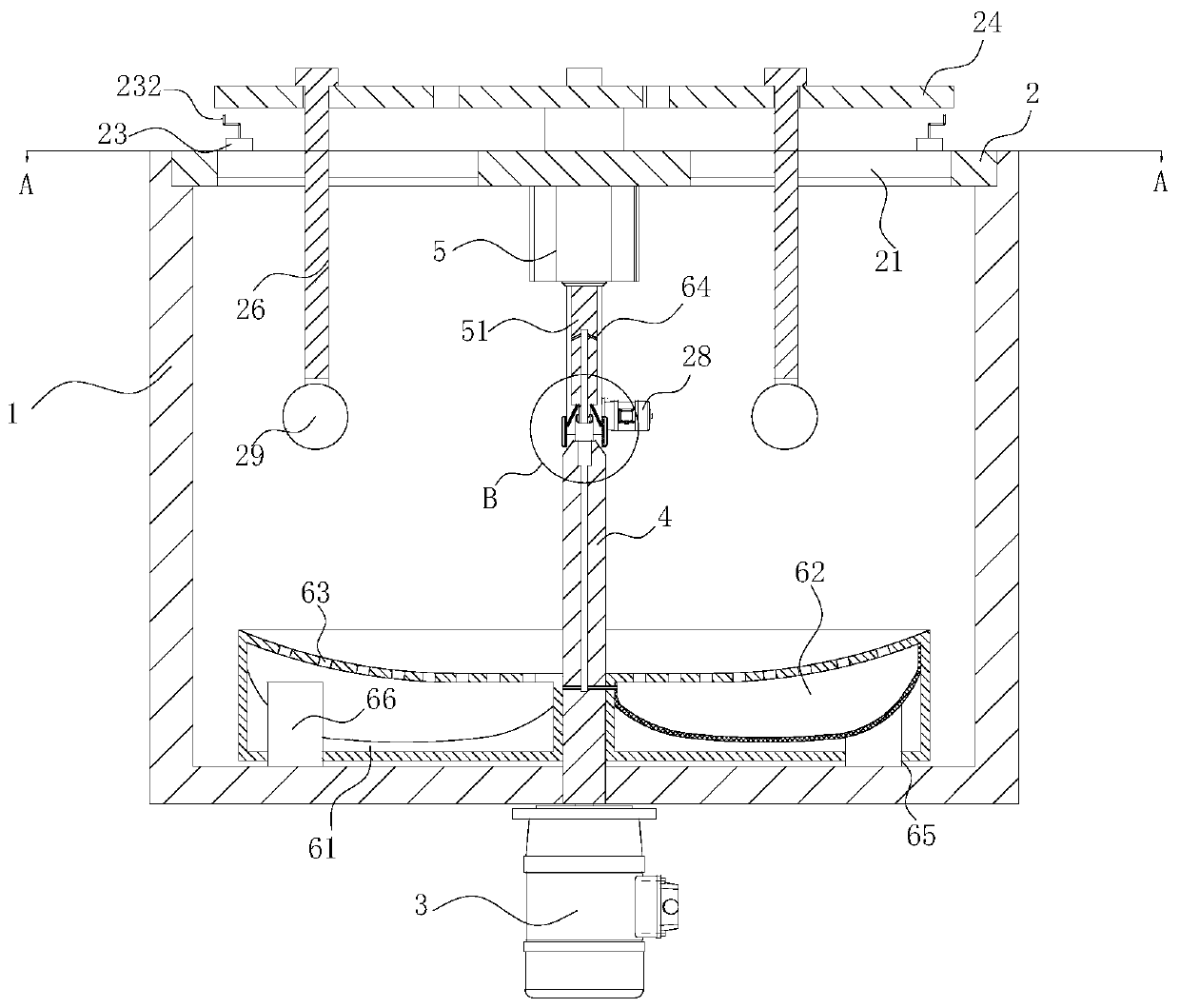

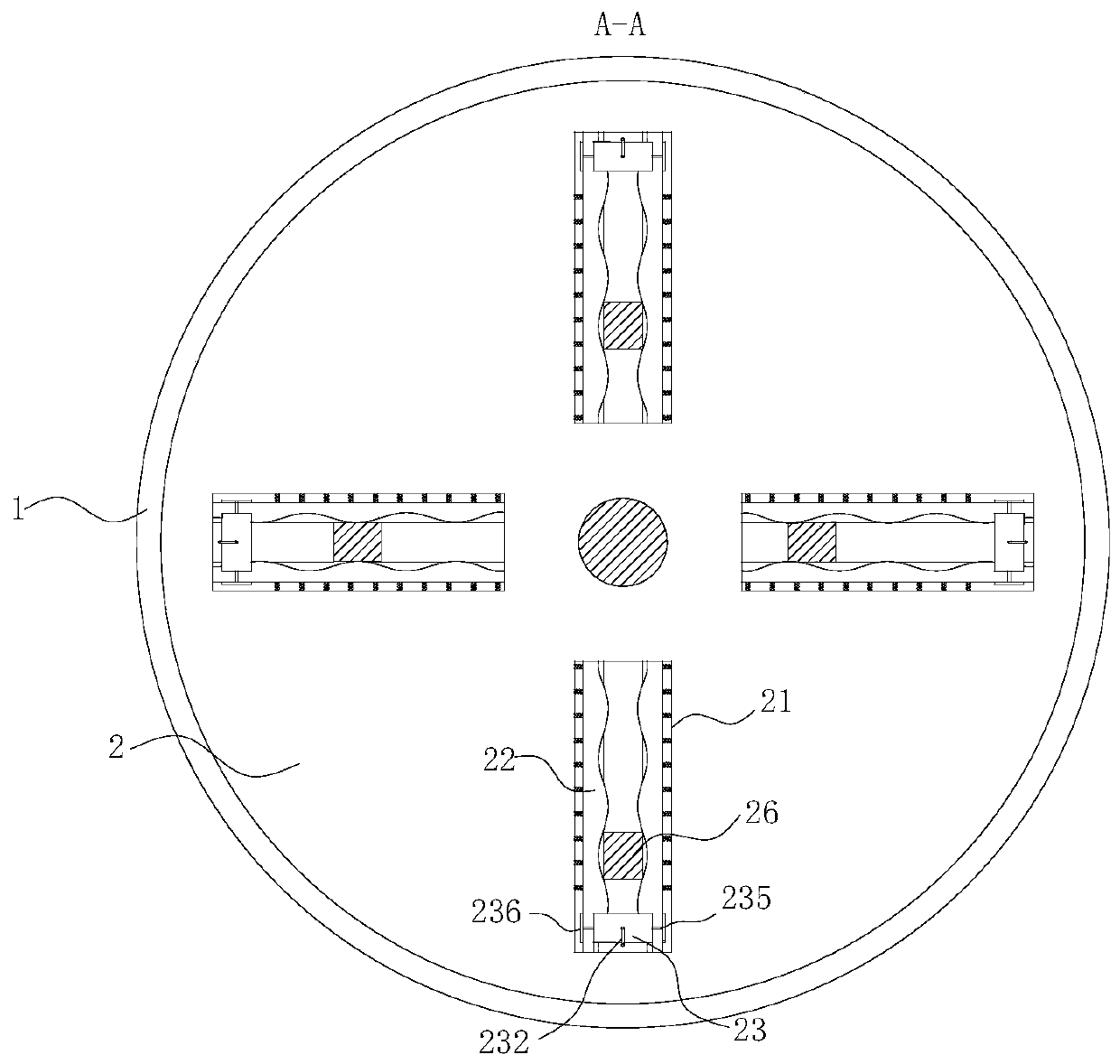

[0026] As an embodiment of the present invention, the fixed cover 2 is fixedly connected with a cylinder 5 on the side surface close to the housing 1; One end of the telescopic shaft 51 is hinged with a support plate 53; the opposite end of the telescopic shaft 51 and the support shaft 4 is designed in a truncated cone shape; during work, the workpiece to be processed is placed on the support shaft 4, and the fixed cover 2 is closed to control the expansion and contraction of the cylinder 5. , so that the telescopic rod moves toward the support shaft 4, the support plate 53 slides on the side of the truncated cone of the support shaft 4, and the rotation of the support rod 52 makes the support plate 53 play a role in fixing the workpiece to be processed, and simultaneously starts the first motor 3 , the first motor 3 drives the support shaft 4 to rotate, and the support plate 53 and the support shaft 4 are fixed at the same time to be processed, which can effectively avoid the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com