Preparation method of low-cost permanent magnetic ferrite material

A technology for the preparation of permanent magnet ferrite, which is applied in the direction of the magnetism of inorganic materials, can solve the problems of reducing the magnetic properties of ferrite, and achieve the effects of low material consumption and energy consumption, low production cost, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

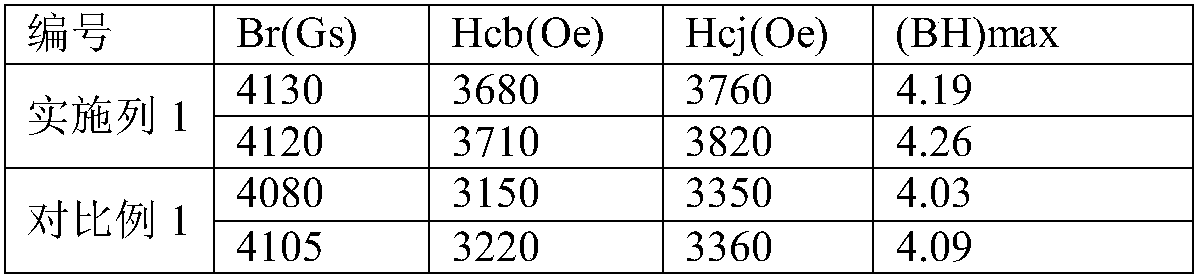

Examples

Embodiment 1

[0034] 1. First, the iron scale is subjected to magnetic separation, and the magnetic metal impurities in the oil are removed by magnetic force, and the iron scale after magnetic separation is dry crushed by a ball mill to less than 10 μm; it is oxidized at 350-850°C for 1-3 hours to oxidize Iron; the oxidized iron scales are wet ball milled again, and ground into fine powder with an average particle size of about 3 μm, and sieved to optimize, remove finer iron powder and large particle iron powder, and then prepare a kind of iron powder with SrFe 11.9 o 19 Pre-fired material for ferrite main phase. Weigh the oxidized iron scale powder (purity ≥ 98.6wt%, the original average particle size of the particles ≤ 3 μm), SrCO 3 (purity≥97wt%, the original average particle size of the particles≤1.5 μm), simultaneously add raw materials such as 0.2wt% boric acid and carry out wet primary ball milling, the ball milling time is 5 hours, the average particle size of the mixed particles i...

Embodiment 2

[0043] 1) Firstly, the iron scale is subjected to magnetic separation, and the magnetic metal impurities in the oil are removed by magnetic force, and the iron scale after magnetic separation is dry crushed by a ball mill to less than 10 μm; it is oxidized into iron oxide at 350°C for 1 hour; The oxidized iron scale is subjected to wet ball milling again, and is ground into a fine powder with an average particle size of about 3 μm, and is sieved and optimized to remove finer iron powder and large particle iron powder, and then prepare a Sr 0.75 Ca 0.05 La 0.1 Fe 11.2 co 0.05 o 19 The calcined material of the ferrite main phase is weighed according to the ratio of the processed iron powder (purity ≥ 98.8wt%, Cl- ≤ 0.2wt%, the original average particle size of the particles ≤ 1.5μm), La 2 o 3 (purity≥99.3wt%, the original average particle size of particles≤5μm), C0 2 o 3 (Co content≥72wt%, original average particle size of particles≤3μm), SrCO 3 (purity≥97wt%, the origin...

Embodiment 3

[0049] 1) Firstly, the iron scale is subjected to magnetic separation, and the magnetic metal impurities in the oil are removed by magnetic force, and the iron scale after magnetic separation is dry crushed by a ball mill to less than 10 μm; it is oxidized into iron oxide at 850°C for 3 hours; The oxidized iron scale is subjected to wet ball milling again, and is ground into a fine powder with an average particle size of about 3 μm, and is sieved and optimized to remove finer iron powder and large particle iron powder, and then prepare a Sr 0.75 Ca 0.05 La 0.1 Fe 11.2 co 0.05 o 19 The calcined material of the ferrite main phase is weighed according to the ratio of the processed iron powder (purity ≥ 98.8wt%, Cl- ≤ 0.2wt%, the original average particle size of the particles ≤ 1.5μm), La 2 o 3 (purity≥99.3wt%, original average particle size of particles≤5μm), Co 2 o 3 (Co content ≥ 72wt%, the original average particle size of the particles ≤ 3 μm), SrCO3 (purity ≥ 97wt%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com