Medical high-polymer non-woven fabric splint

A technology of non-woven fabrics and polymers, applied in medical science, fractures, etc., can solve the problems of unfavorable general adoption and high production costs, and achieve the effects of cost reduction, good consistency, and simple and reliable production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

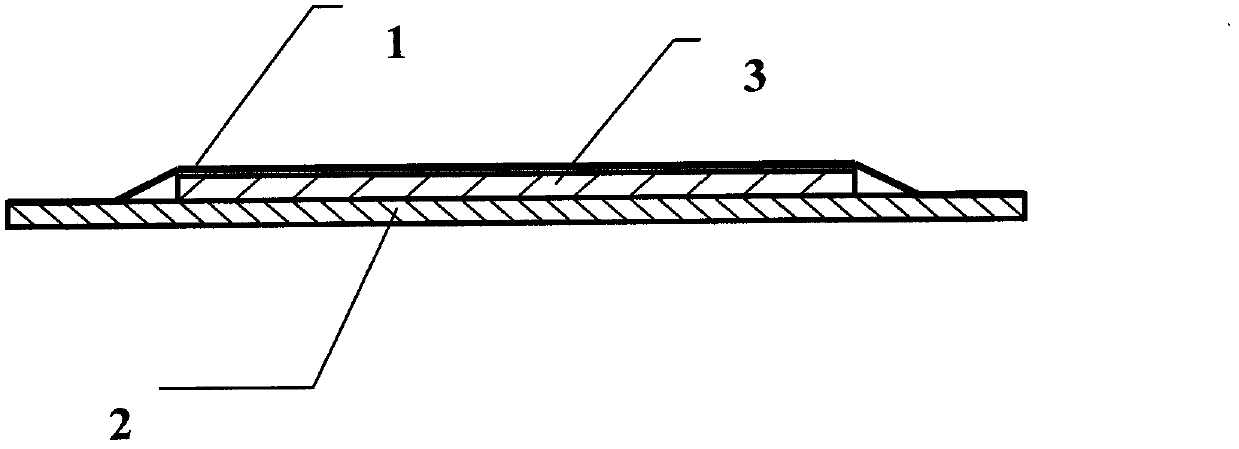

[0015] In the figure, the medical polymer non-woven splint is mainly composed of waterproof layer 1, buffer layer 2, skeleton layer 3 and so on.

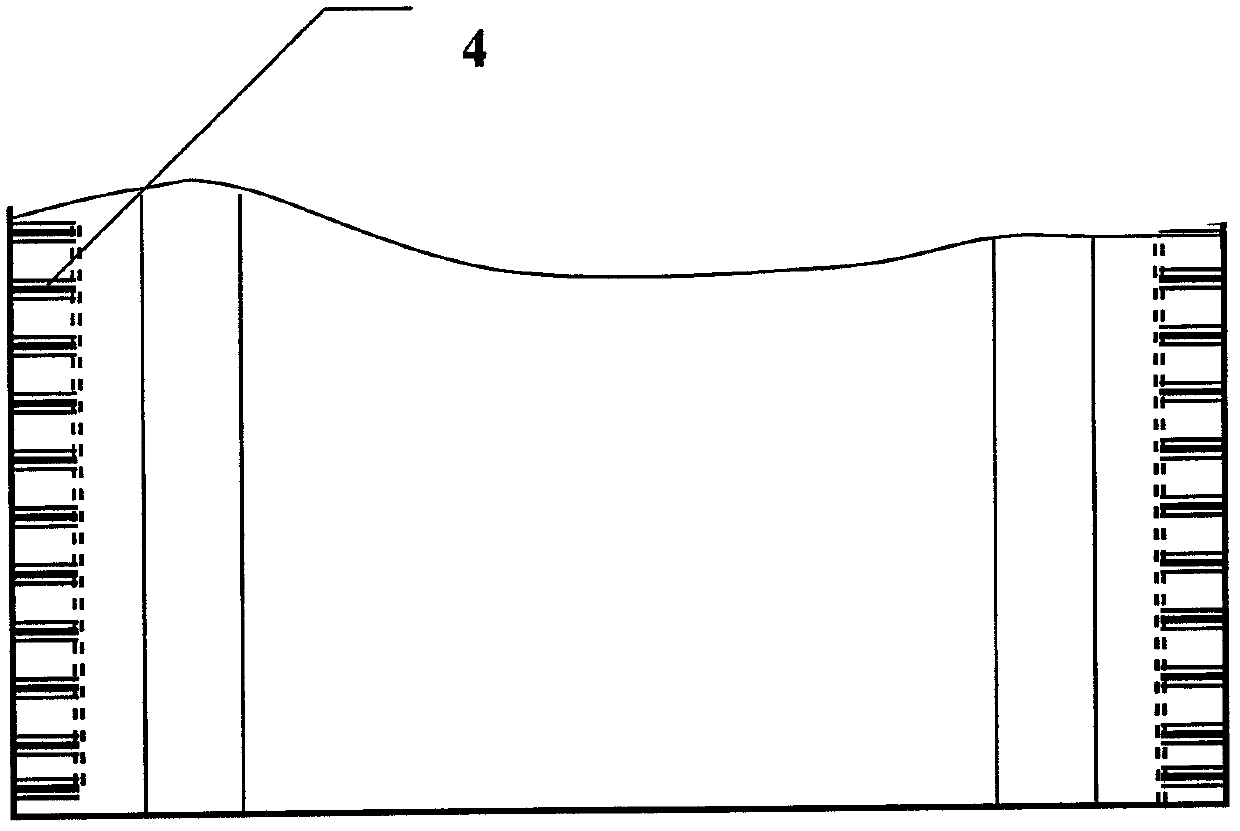

[0016] The waterproof layer 1 , skeleton layer 3 , and buffer layer 2 are superimposed, and the waterproof layer and the buffer layer are compounded through stitching points 4 .

[0017] The waterproof layer 1, cushioning layer 2, and skeleton layer 3 are usually chemical fiber fabrics, wherein the thickness of the waterproof layer 1 is 0.2-0.5 mm, the thickness of the skeleton layer 3 and the buffer layer 2 is 4-6 mm, and the thickness of the waterproof layer 1 is preferably 0.5 mm. mm, the thickness of the skeleton layer 3 is 5.25 mm, and the thickness of the buffer layer 2 is 5.7 mm.

[0018] The skeleton layer 3 is usually coated with a water-curable polyurethane prepolymer.

[0019] The stitching points 4 are arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com