U-shaped tool device for prestressed steel structure tensioning construction and construction method

A prestressed steel and tensioning technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of limited pre-tensioning force and large volume, and achieve integrity assurance, clear force transmission route, and complex changes The effect of bulky craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

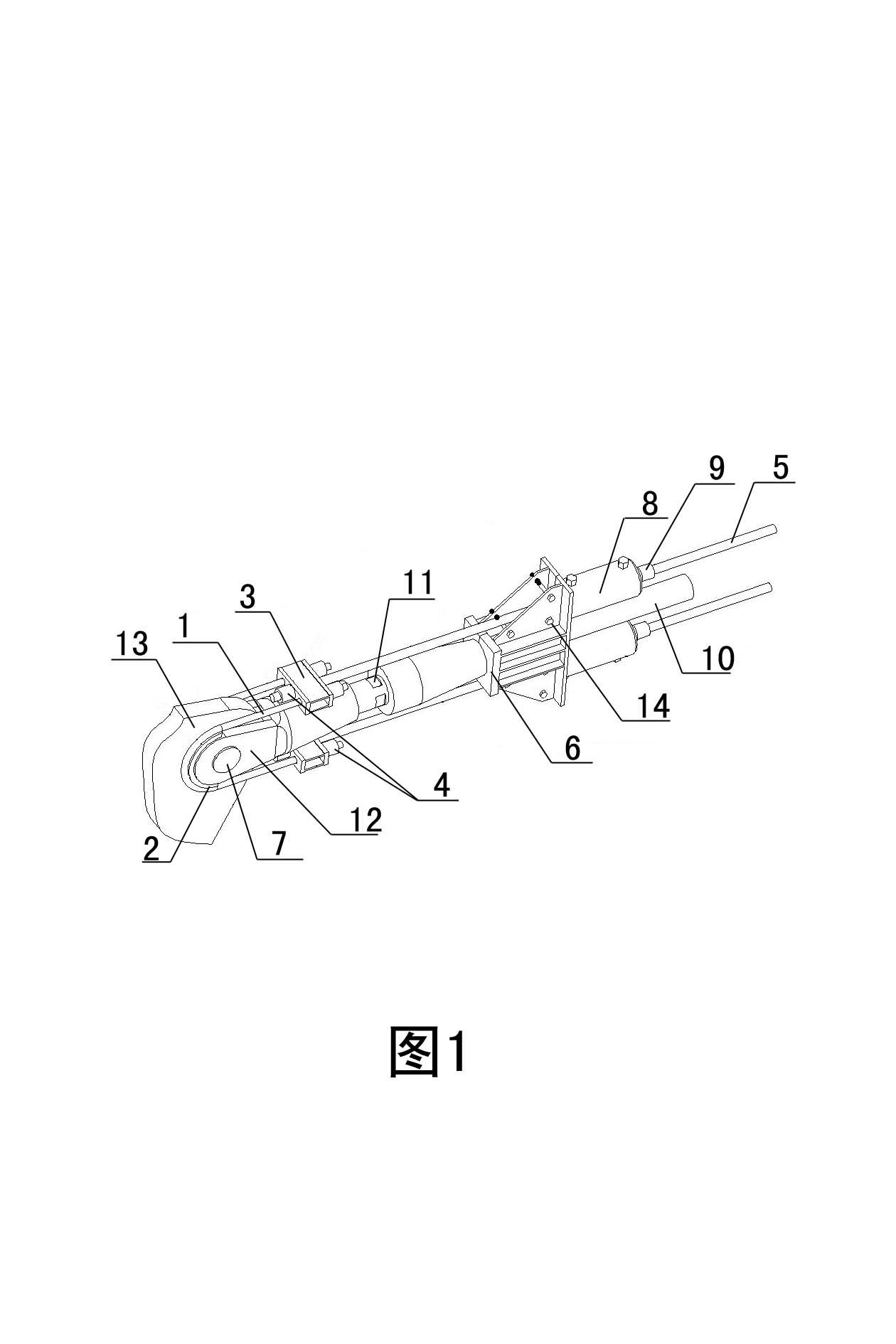

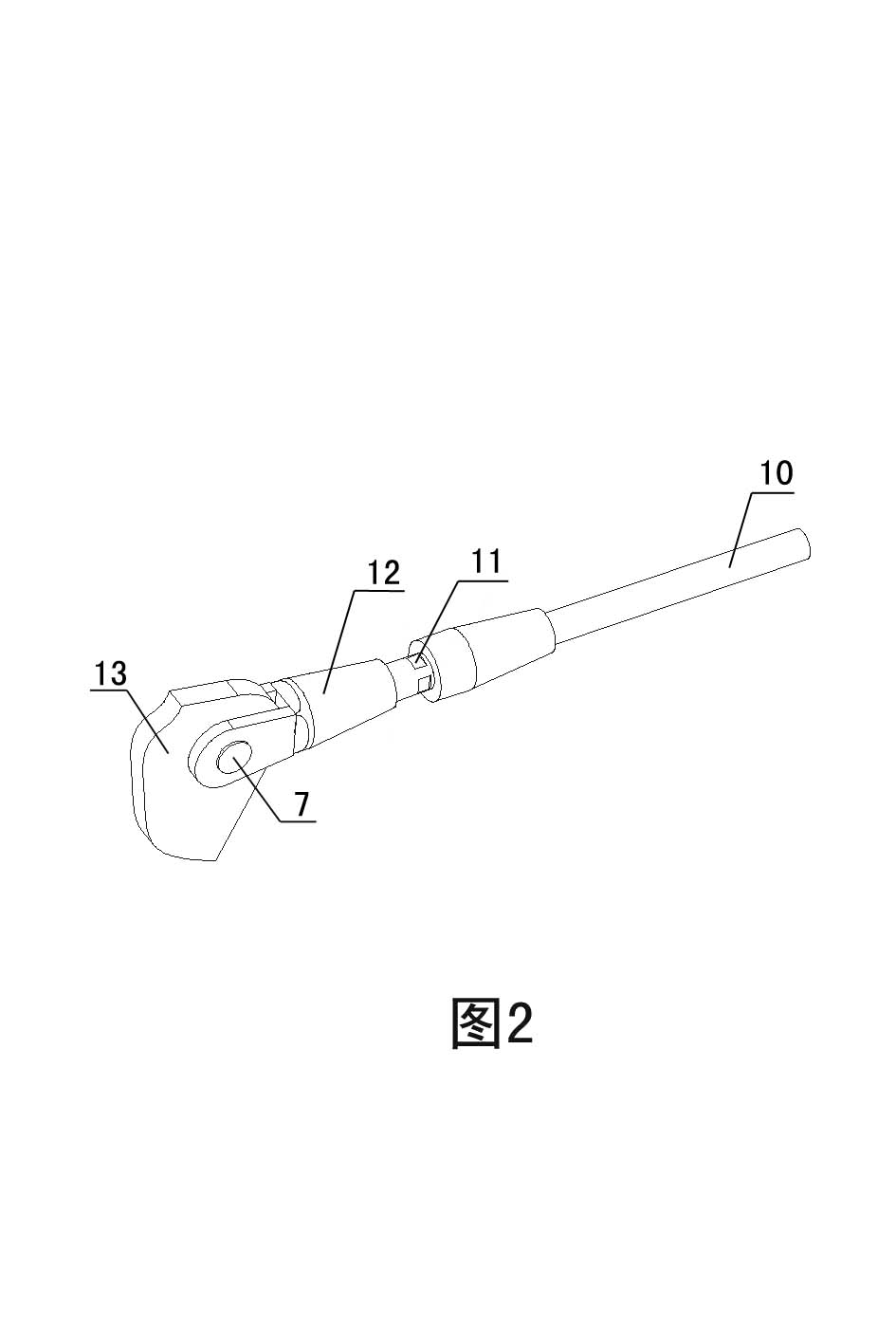

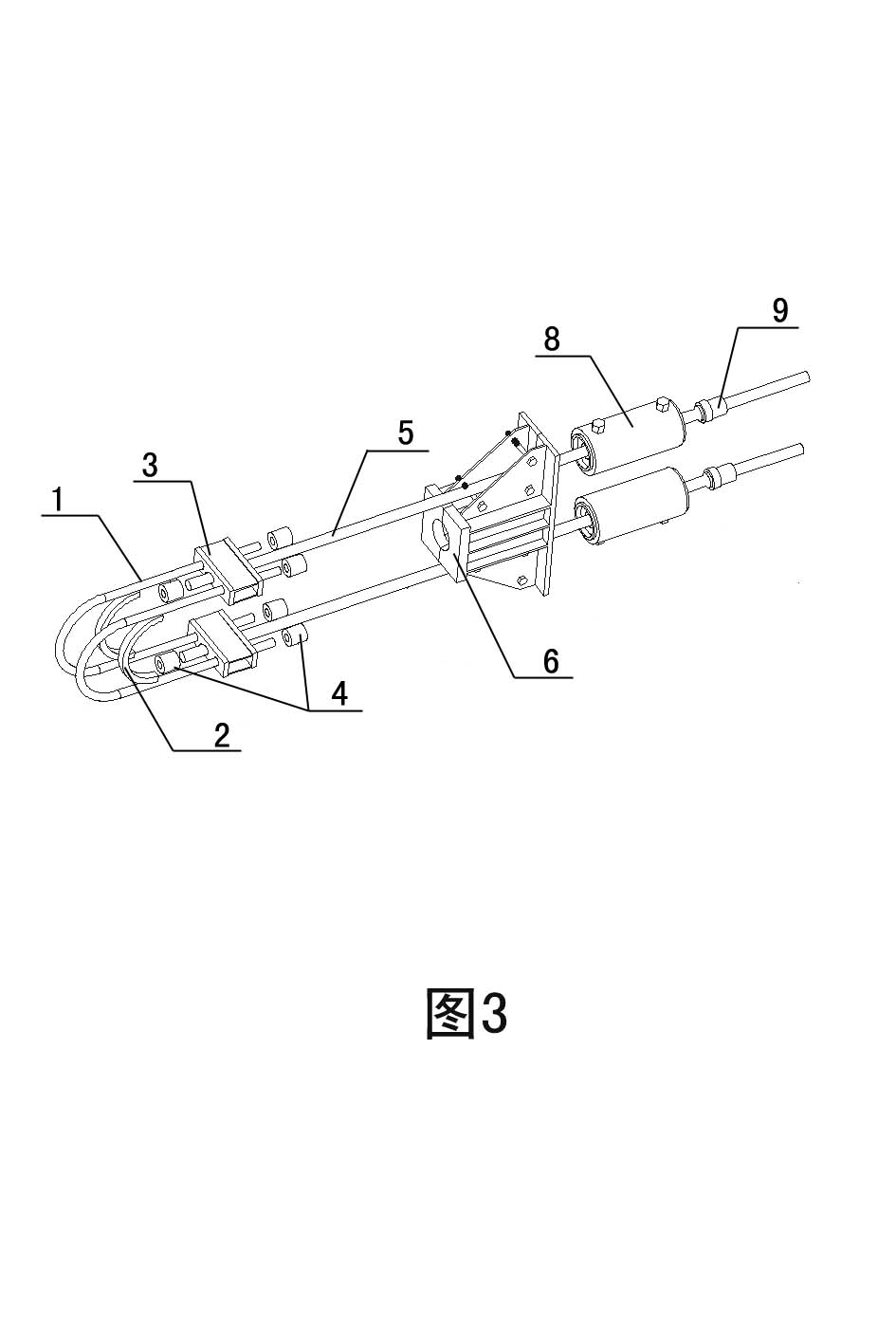

[0037] Examples see Figure 1 to Figure 5 As shown, a U-shaped tooling device for tensioning construction of a prestressed steel structure includes a tensioning screw 5, a load-bearing frame connected to a steel cable 10, and a tensioning jack 8. The anchor head of the steel cable 10 is made of The fork lug anchor head 12 connected by the pin shaft 7 and the lug plate 13, the middle round steel of the steel cable 10 has a step change in section, and the bearing frame includes two U-shaped bearing pull rings 1 and two conversion boxes 3 and a cable cervical bearing seat 6, the arc-shaped parts of the two U-shaped load-bearing pull rings 1 are pressed tightly on the two fork-shaped auricles of the fork ear anchor head 12, and each U-shaped load-bearing pull The two free ends of the ring 1 pass through a conversion box 3 respectively, and are fixed by the lock nut 4. Each conversion box 3 has a through hole between the two free ends passing through the U-shaped load-bearing pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com