Method for quickly preparing rapid-charging graphene-based positive electrode material

A graphene-based, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of unsuitable control of the purity of lithium iron phosphate, inability of graphene to be uniformly dispersed, and easy to grow and agglomerate grains. Stability, simple and reliable production process, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

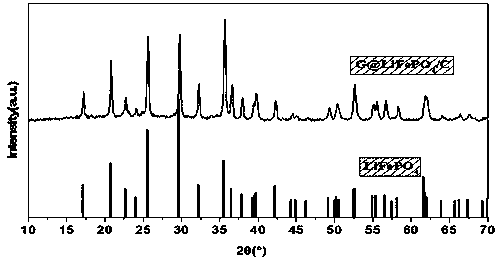

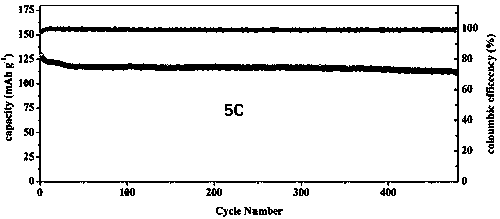

[0016] 1. Batching process: use an electronic balance to accurately weigh 30.3 g of ferric nitrate nonahydrate, 10.0 g of citric acid monohydrate, and 7.8 g of lithium dihydrogen phosphate to prepare an orange-yellow solution, and then add the graphene oxide solution dropwise to the previous solution , sonicate for 0.5h, and stir for more than 1h to obtain a spray precursor.

[0017] 2. Spray pyrolysis process; turn on the tube furnace to heat to the specified temperature, with H 2 / Ar mixed gas is passed into the spray pyrolysis system as the reducing gas and carrier gas, and the micron-sized liquid droplets produced by the ultrasonic atomizer are brought into the pyrolysis reaction furnace by the carrier gas, and the drying and thermal decomposition are completed at high temperature. The physical and chemical reaction process forms regular spherical particles.

[0018] 3. Collection; the black powder collected at the collector is the final product. The collector must mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com