Method for preparing decellularized lamellar cornea matrix sheet

A technology of lamellar cornea and corneal stroma, applied in the field of biomedical tissue engineering, can solve the problem of biocompatibility, strength, degradation rate, transparency, homology, antigenic and pathogenic defects, and easily damaged tissue structure , affect the transparency of the cornea and other issues, to achieve the effect of simple and reliable production process, complete decellularization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

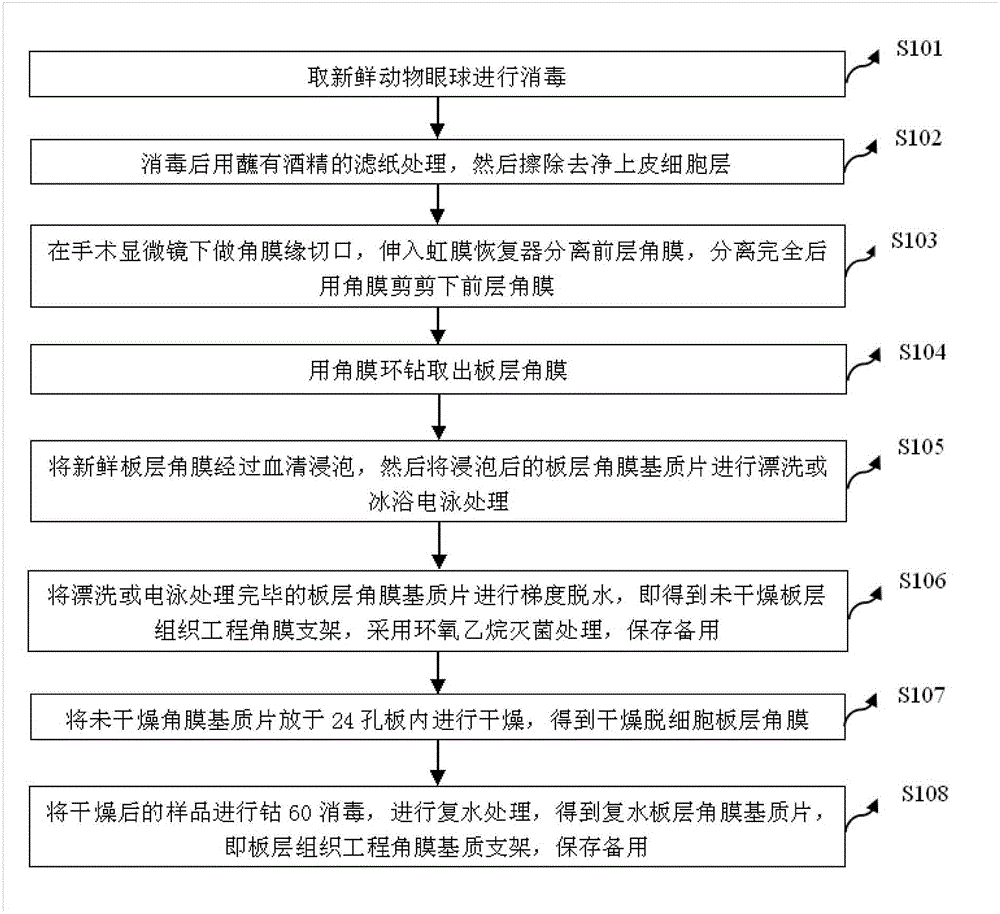

[0035] figure 1 The implementation flow of the method for preparing the decellularized lamellar corneal stromal sheet provided by the embodiment of the present invention is shown. The method includes the following steps:

[0036] In step S101, fresh animal eyeballs are taken for disinfection;

[0037] In step S102, after disinfection, it is treated with filter paper dipped in alcohol, and then the epithelial cell layer is wiped off;

[0038] In step S103, make a limbal incision under the operating microscope, insert the iris restorer to separate the anterior cornea, and cut off the anterior cornea with corneal scissors after the separation is complete;

[0039] In step S104, the lamellar cornea is taken out with a corneal trephine;

[0040] In step S105, the fresh lamellar cornea is soaked in serum, and then the soaked lamellar corneal stroma is rinsed or treated by ice bath electrophoresis;

[0041] In step S106, the lamellar corneal stroma sheet that has been rinsed or e...

Embodiment 1

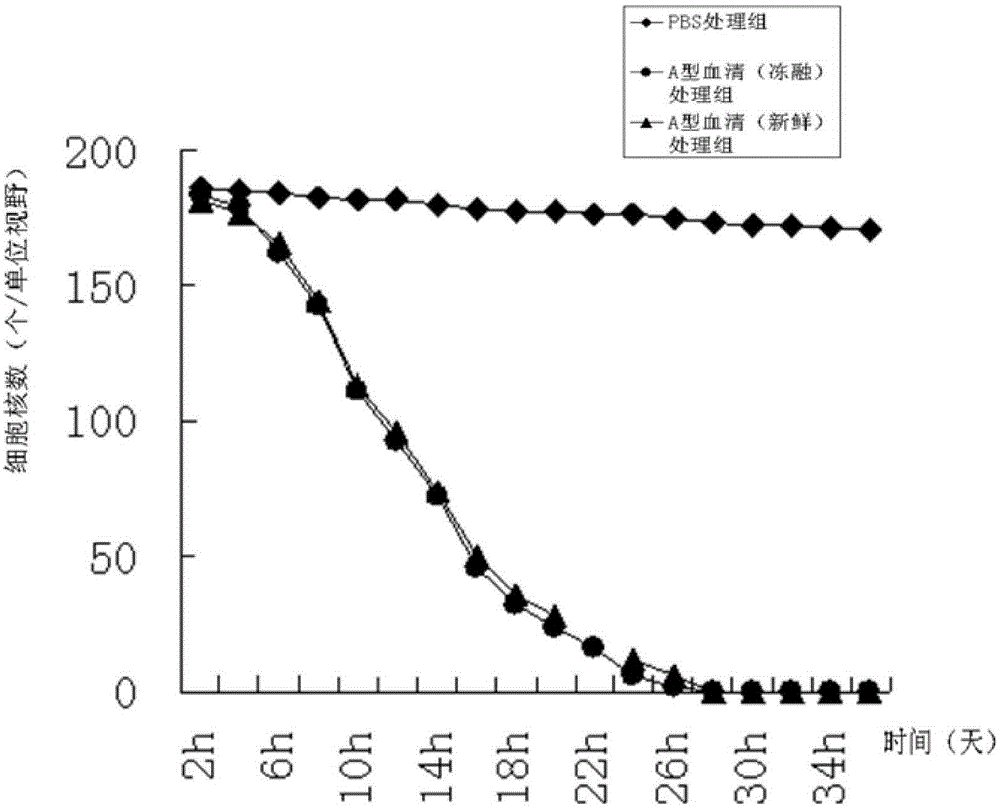

[0052] Disinfect fresh animal eyeballs by immersing them in 0.5-2% iodophor for 2-5 minutes. After soaking, rinse them with PBS for 5 minutes each time; Cover the surface of the cornea with filter paper or soak it directly for 1-5min, then gently wipe the epithelial cell layer with a cotton swab / corneal epidermis knife; make a limbal incision with a jewel knife under the operating microscope, and insert the iris restorer to separate the anterior cornea After the separation is complete, use corneal scissors to cut off the anterior cornea. The limbal incision is about 1 / 3 deep, 0.2-0.8mm thick, and 3mm long. The thickness of the separated lamellar layer is 0.2-0.8mm, or directly use lamellar cornea Separate the anterior lamellar cornea about 1 / 3 deep (about 0.2-0.8mm thick) with a splitting knife; then put the separated anterior lamellar cornea on the corneal pillow (the anterior elastic layer faces down), and use a corneal trephine to remove 3-10mm diameter lamellar cornea; the...

Embodiment 2

[0054] Disinfect fresh animal eyeballs by immersing them in PBS containing antibiotics for 5-10 minutes. After soaking, wash three times with PBS for 5 minutes each time; after disinfection, cover the surface of the cornea with filter paper dipped in 15-30% alcohol or directly soak for 1-5 minutes, and then use a cotton swab / The corneal epidermis gently wipes off the epithelial cell layer; under the operating microscope, use a gemstone knife to make a limbal incision, insert the iris restorer to separate the anterior cornea, and cut off the anterior cornea with corneal scissors after the separation is complete. The limbal incision is deep About 1 / 3, the thickness is 0.2-0.8mm, the length is 3mm, the thickness of the separated lamellar layer is 0.2-0.8mm, or the depth of about 1 / 3 (thickness is about 0.2-0.8mm) is directly separated with a lamellar keratectomy knife Anterior lamellar cornea; then put the separated anterior lamellar cornea on the corneal pillow (the anterior el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com