Patents

Literature

90results about How to "Machinable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-strength solid buoyancy material

The invention discloses a method for preparing a high-strength solid buoyancy material. The method comprises the steps as follows: a coupling agent in a mass ratio of (0.2:100) with hollow microspheres is adopted to perform pretreatment on 1-20 parts of hollow microspheres; 100 parts of resin, 0-60 parts of a curing agent, 0-15 parts of a toughening agent, 0-5 parts of a dispersing agent and 0-10 parts of a diluent are stirred and mixed to obtain a resin system material, the pretreated hollow microspheres and 1-30 parts of small fiber balls are gradually added into the resin system material step by step, the mixture is slow stirred and uniformly mixed, and original slurry is obtained; and the original slurry enters an injection molding process and is subjected to demolding so as to obtain the high-strength solid buoyancy material. Compared with a traditional solid buoyancy material, the high-strength solid buoyancy material has higher compressive strength, lower density and water permeability and good processability simultaneously.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

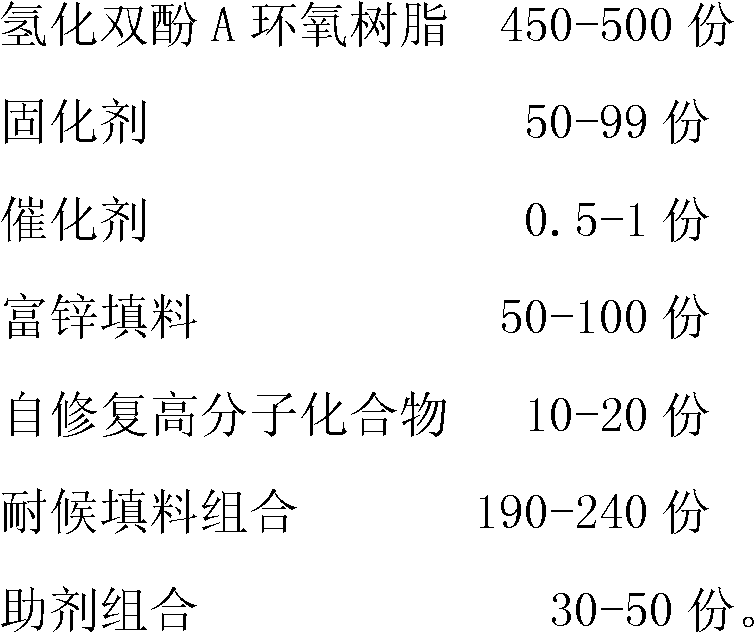

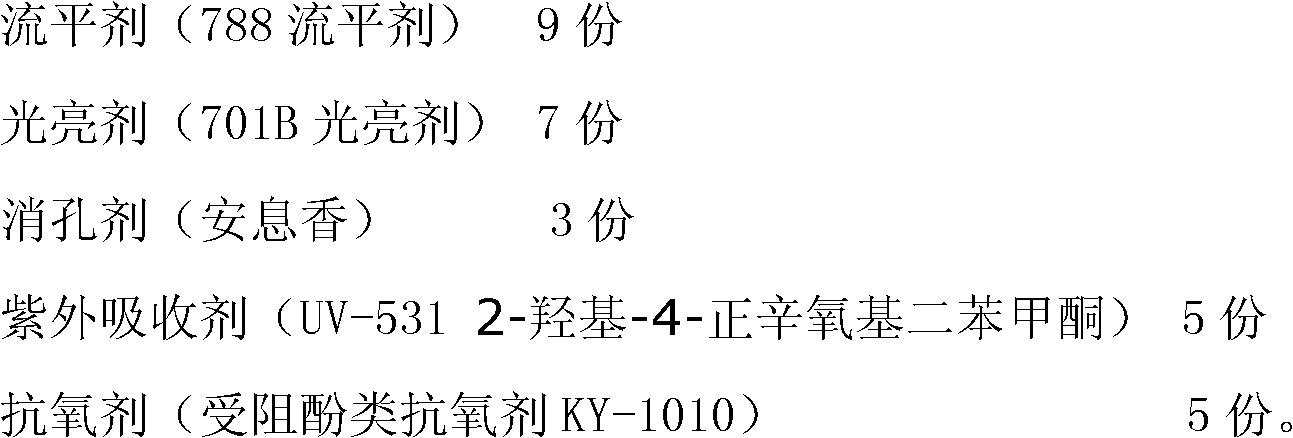

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266AGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsDry mixingHeavy duty

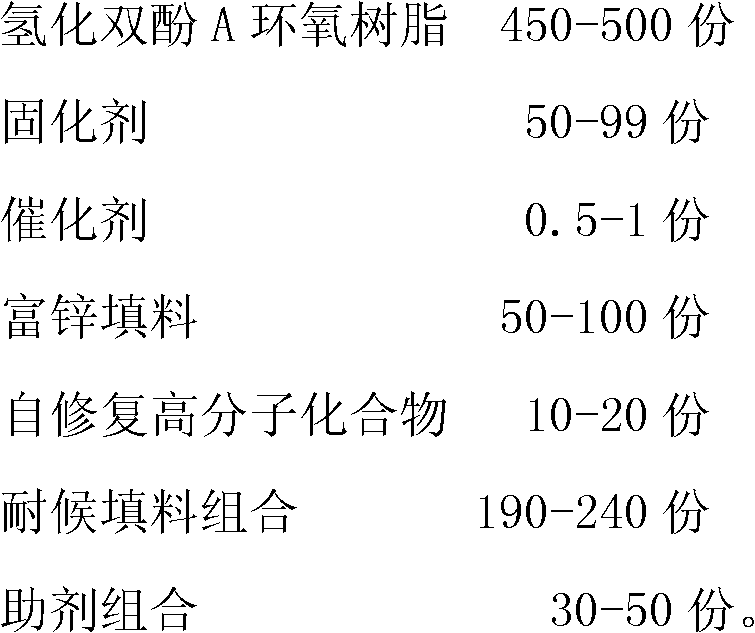

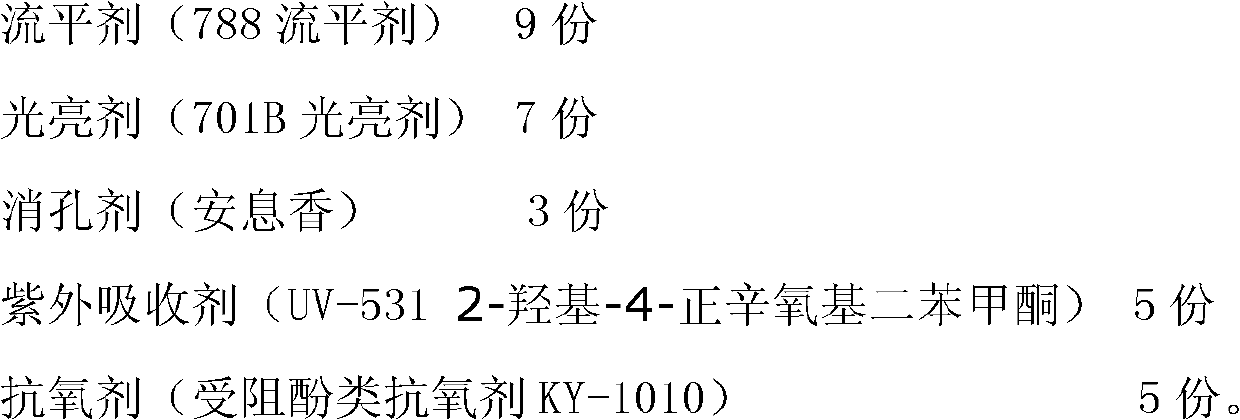

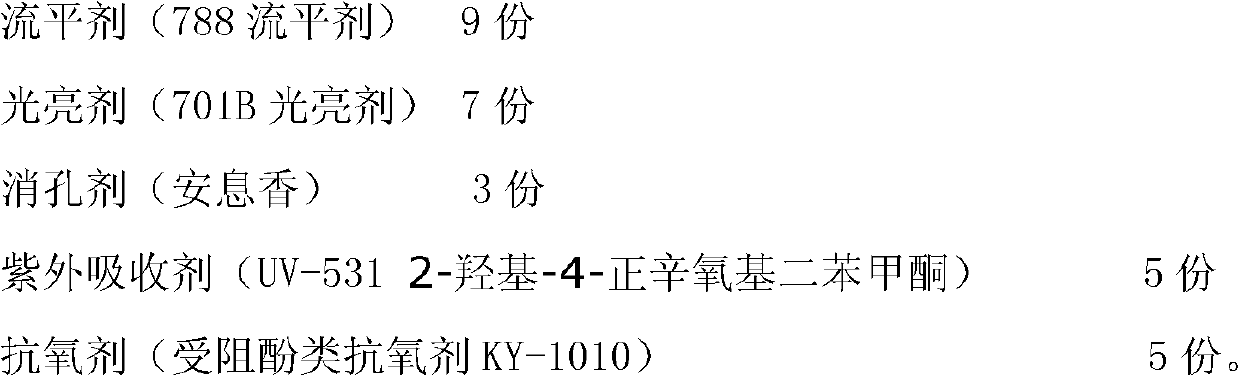

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

Powder ash air-entrained concrete building block and preparation method thereof

InactiveCN101913902ALose weightSmall sizeSolid waste managementCeramic shaping apparatusFire protectionEnergy consumption

The invention discloses a powder ash air-entrained concrete building block and a preparation method thereof. The powder ash air-entrained concrete building block is prepared by adding water to 100-200kg of cement, 350-380kg of lime, 1350-1550kg of powder ash, 1.4-1.5kg of aluminite powder and 0.195-0.205kg of foam stabilizers. The preparation method comprises the following steps of raw material preparation, metering, stirring, pouring in a mould, standing for procuring, demoulding, swinging to cutting parts for cutting, steaming and curing in a reactor and finished product warehousing. The building block has the advantages of light weight, good heat insulation, machinability, convenient construction, wide source of raw materials, high production efficiency, low production energy consumption and good fire protection and sound insulation, wherein the dry volume density of the building block is 500-700kg / m3 and amounts to one third of a clay brick; as a large quantity of air holes and micro holes are arranged inside the building block, the building block has favorable heat insulation; as coarse aggregates are not used, the building block has favorable machinability, can be sawn, dug,drilled and nailed and bonded by bonding materials, thereby providing beneficial conditions for building construction; and the building block belongs to a green environmental-protection product.

Owner:舟山市宇锦新型墙体材料有限公司

Steamed aerated concrete

InactiveCN101327621ALarge plane utilization factorLight weightCement mixing apparatusSold ingredients supply apparatusFoaming agentCoal

The present invention relates to an autoclaved aerated concrete, which is composed of lime, cement, coal ash or quartz sand, gypsum, foaming agent and admixture. The autoclaved aerated concrete has the advantages of light volume weight, good heat-preserving property, large building plane utilization coefficient, processibility, and good fireproof property.

Owner:SHANGHAI LIANGPU NEW WALL MATERIALS

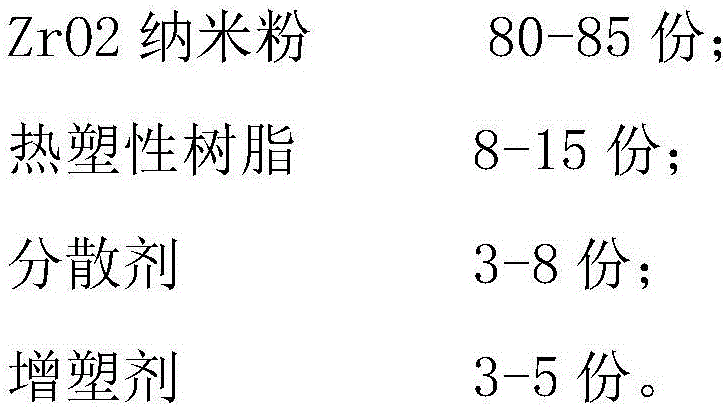

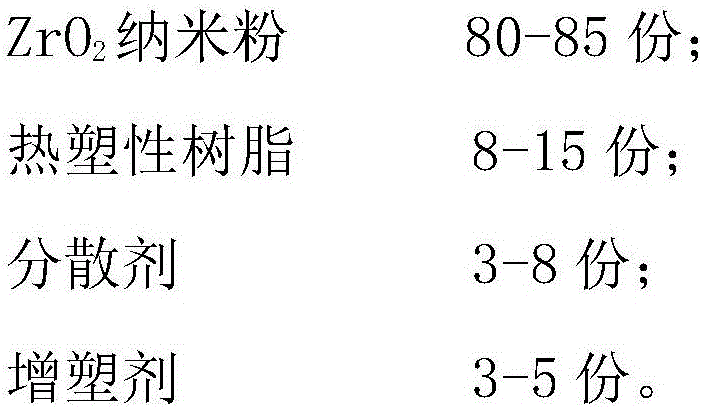

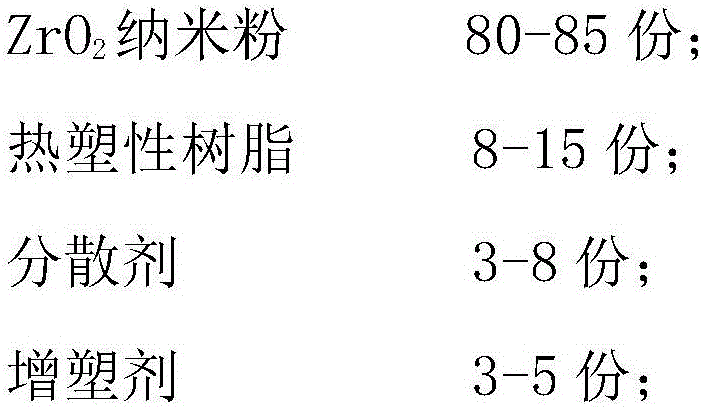

Cement-based compound material used for mobile phone shell and ceramic-based compound material mobile phone shell

The invention provides a cement-based compound material used for a mobile phone shell and a ceramic-based compound material mobile phone shell and a preparation method thereof. The cement-based compound material used for the mobile phone shell is prepared from, by weight, 80-85 parts of ZrO2 nano powder, 8-15 parts of thermoplastic resin, 3-8 parts of a dispersing agent and 3-5 parts of a plasticizer. The cement-based compound material used for the mobile phone shell integrates noble texture of ceramics and toughness and plasticity of macromolecules, and can be machined. Leftover materials can be conveniently recycled, and the cement-based compound material is low in cost and suitable for large-scale industrial production.

Owner:SHENZHEN PENGHUI FUNCTIONAL MATERIAL CO LTD

Highly tenacious soluble composite material salt core and production method

InactiveCN101269401AHigh strengthImprove plasticityFoundry mouldsMould handling/dressing devicesFiberHigh intensity

The invention provides a high-strength soluble composite material salt core and a preparation method thereof. The salt core is made from soluble metal salt crystal, binder, oxide fiber and metal composite salt; and the preparation method is as follows: the metal salt, the binder, the fiber and the salt crystal are evenly mixed in proportion and then arranged into a die for pressing into salt core blank, then the salt core blank is arranged into a furnace for braking, the salt core after cooling is processed mechanically according to a concrete size, at last, the processed salt core is packaged. The high-strength soluble composite material salt core provided by the invention can bear no more than 200 MPa metal liquid pressure, and can be used for making complex cavities of components by squeezing forging, low pressure forging and metal forging.

Owner:XIAN KANGBO NEW MATERIAL TECH

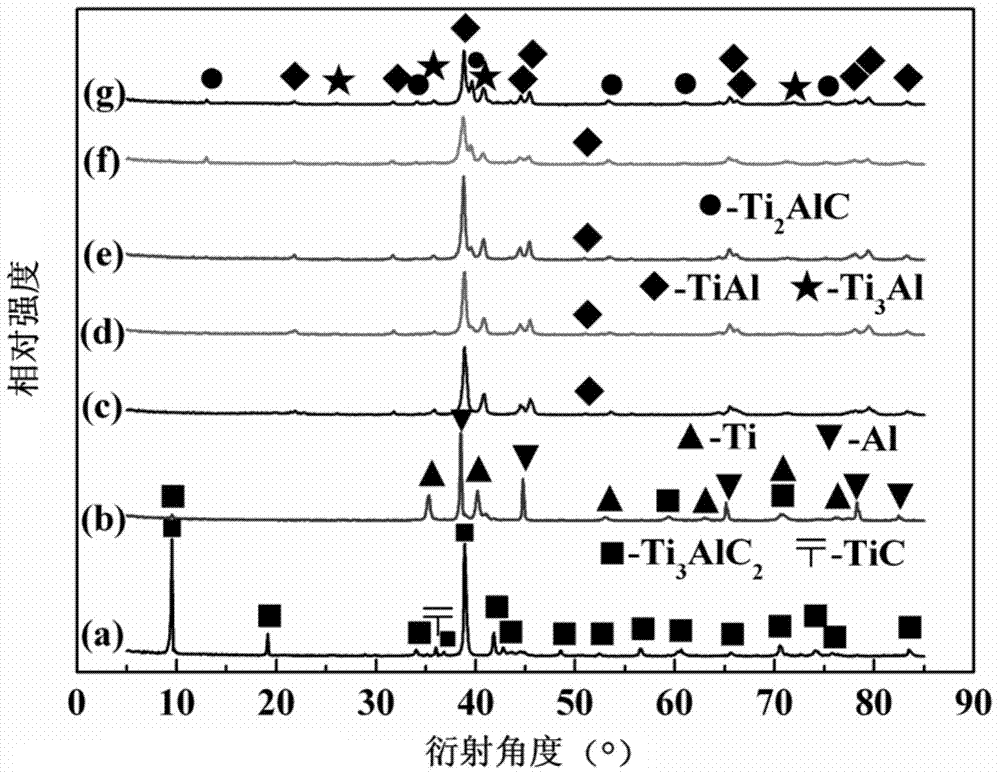

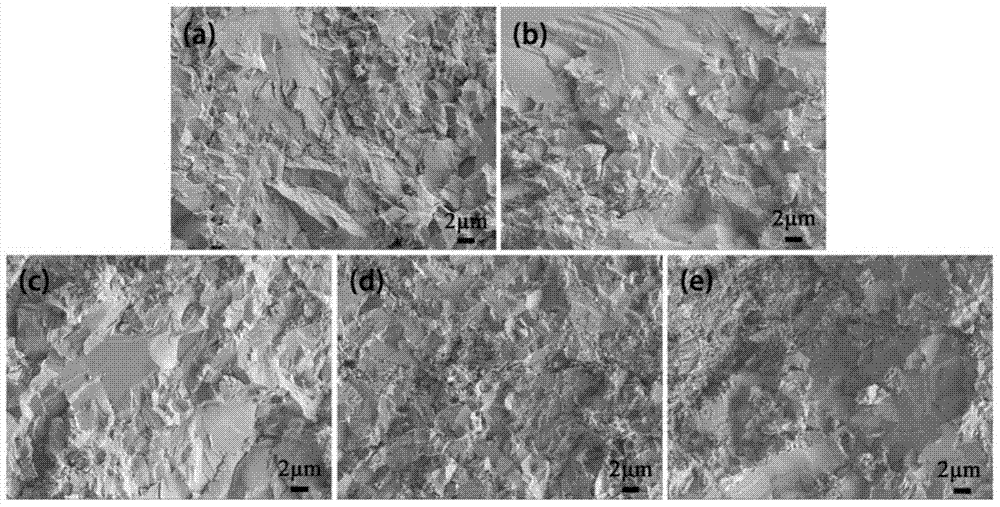

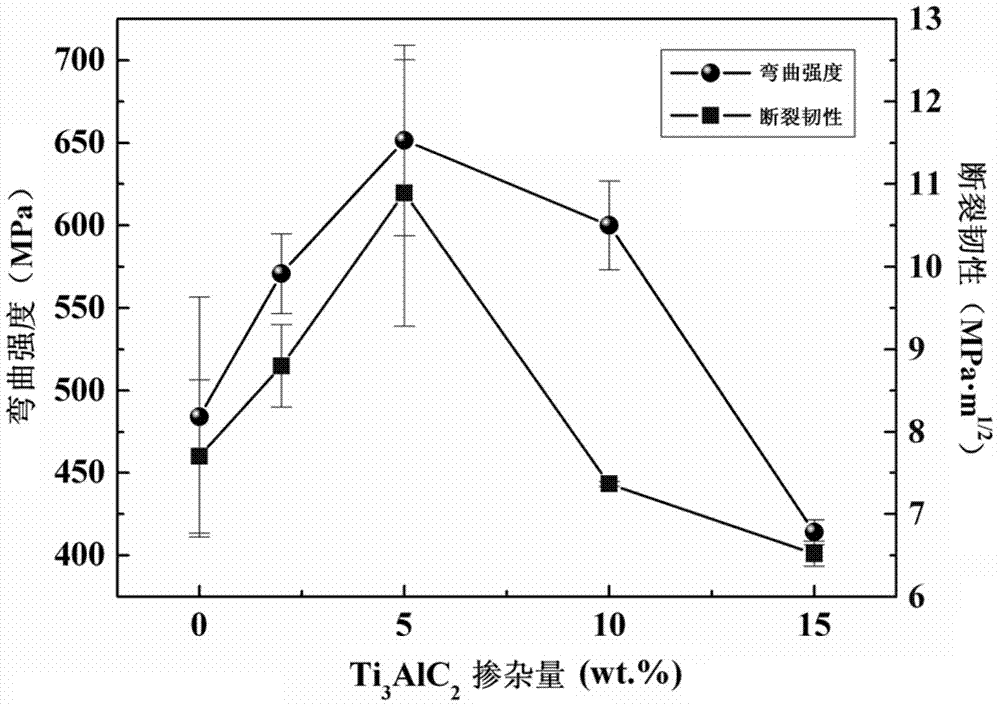

Ti2AlC/TiAl based composite material and low-temperature preparation method thereof

InactiveCN103757452ASynthesis temperature is lowLow process controllabilityAl powderUltimate tensile strength

The invention discloses a Ti2AlC / TiAl based composite material and a low-temperature preparation method thereof. The Ti2AlC / TiAl based composite material is prepared by steps of uniformly ball-milling Ti powder, Al powder and Ti3AlC2 powder, then performing cold press molding firstly, and finally performing vacuum hot pressing and sintering at 950-1,050 DEG C. The material consists of two parts, namely, base phase TiAl, Ti3Al and enhancing phase Ti2AlC, without impurity phase TiC. The base phase is formed through in-situ exothermic reaction between Ti and Al, Ti3AlC2 has a self-decomposition reaction to obtain the Ti2AlC enhancing phase, the synthesis temperature of the Ti2AlC / TiAl based composite material is reduced, the material is simple in process, high in controllability, low in sintering temperature, low in preparation cost, high in product purity, low in impurity content and remarkable in toughening effect, the maximum bending strength of the prepared material is 651MPa, and the maximum breaking tenacity is 10.89MPa.m<1 / 2>.

Owner:SHAANXI UNIV OF TECH

Low-density high-strength solid buoyancy material and preparation method thereof

The invention discloses a low-density high-strength solid buoyancy material and a preparation method thereof, belongs to the field of solid buoyancy materials for marine environments, and can be used for marine submersible buoys, marine drilling platforms, various deep submergence vehicles, seabed space stations and the like. The low-density high-strength solid buoyancy material comprises the following raw materials in parts by weight: 100 parts of epoxy resin, 0-20 parts of a toughening modification agent, 10-80 parts of a curing agent, 0.5-5 parts of a catalyst, 0.2-10 parts of a dispersion agent, 10-200 parts of micron hollow glass beads, 10-150 parts of millimeter hollow glass beads and 0.2-5 parts of a coupling agent. The preparation method comprises the following steps: adding the accurately weighed raw materials into a kneading machine, heating to 80-100 DEG C, and stirring for 30 minutes at a uniform speed to obtain a mixture; taking out and putting the mixture into a mould, compacting, putting on a pressure curing machine, pressing, heating and deflating, curing for a certain time, and shaping to prepare a buoyancy material standard module. The low-density high-strength solid buoyancy material is used for solving the problem of higher density of a solid buoyancy material and increasing the net buoyancy of the solid buoyancy material.

Owner:滕州市华海新型保温材料有限公司

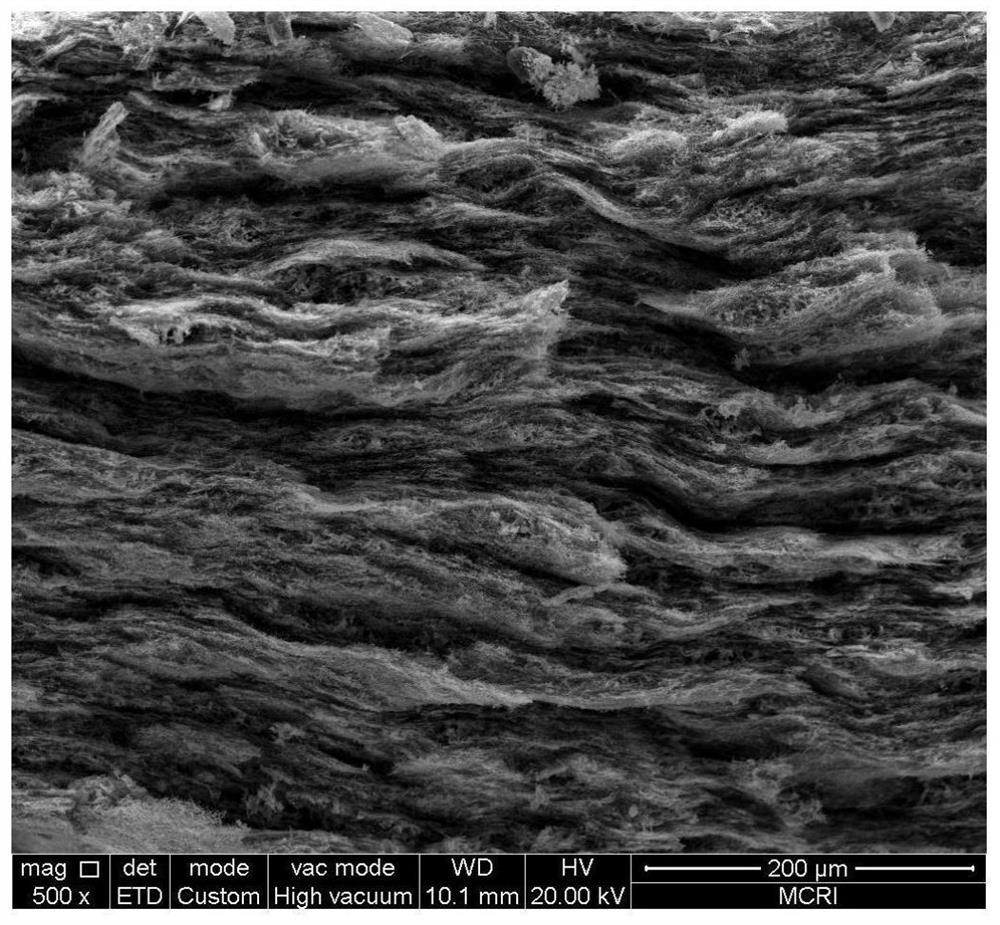

Carbon foam in-situ reinforced carbon aerogel high-temperature thermal insulation material and preparation method thereof

ActiveCN103044057AHigh temperature resistanceLow thermal conductivityThermal insulationCarbonization

The invention relates to a carbon foam in-situ reinforced carbon aerogel high-temperature thermal insulation material and a preparation method thereof; the carbon foam in-situ reinforced carbon aerogel high-temperature thermal insulation material has the characteristics of high temperature resistance, low heat conductivity and high strength, and is applicable to thermal protection system of the hypersonic speed aircraft, belonging to the technical field of high-temperature thermal insulation material. The thermal insulation material takes carbon foam which is formed in an in-situ manner as a reinforcing skeleton and carbon aerogel as a substrate, and eliminates pores between the carbon foam skeleton and the carbon aerogel caused by the conventional reinforcing method through a common carbonization; the prepared carbon foam reinforced carbon aerogel has the characteristics of high temperature resistance, low heat conductivity and high strength, and is machinable; the room temperature heat conductivity can be reduced to 0.04W / m.k, and the maximum use temperature in an inert atmosphere can reach 3000 DEG C.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Production method of aerated concrete plate

InactiveCN107984608AReduce weightImprove insulation effectCeramic shaping apparatusCeramicwareCalcium in biologyChemical reaction

The invention relates to the technical field of concrete plates, in particular to an aerated concrete plate, and provides a production method of the aerated concrete plate. The production method comprises the production steps of raw material preparation, steel bar processing, steel bar mesh assembling, batching, pouring, still standing, cutting, autoclaved curing and taking out of a kettle. Aerated concrete is porous silicate concrete manufactured in the modes that a siliceous material and a calcareous material serve as main raw materials, a gas forming agent is doped, water is added for stirring, pores are formed through a chemical reaction, and the technological processes such as pouring molding, pre-curing cutting and steam curing are conducted. The concrete plate obtained through the technological method is low in weight and good in heat insulation performance, harmful gas is not emitted, and processibility is achieved.

Owner:陕西人达路农副产品加工有限公司

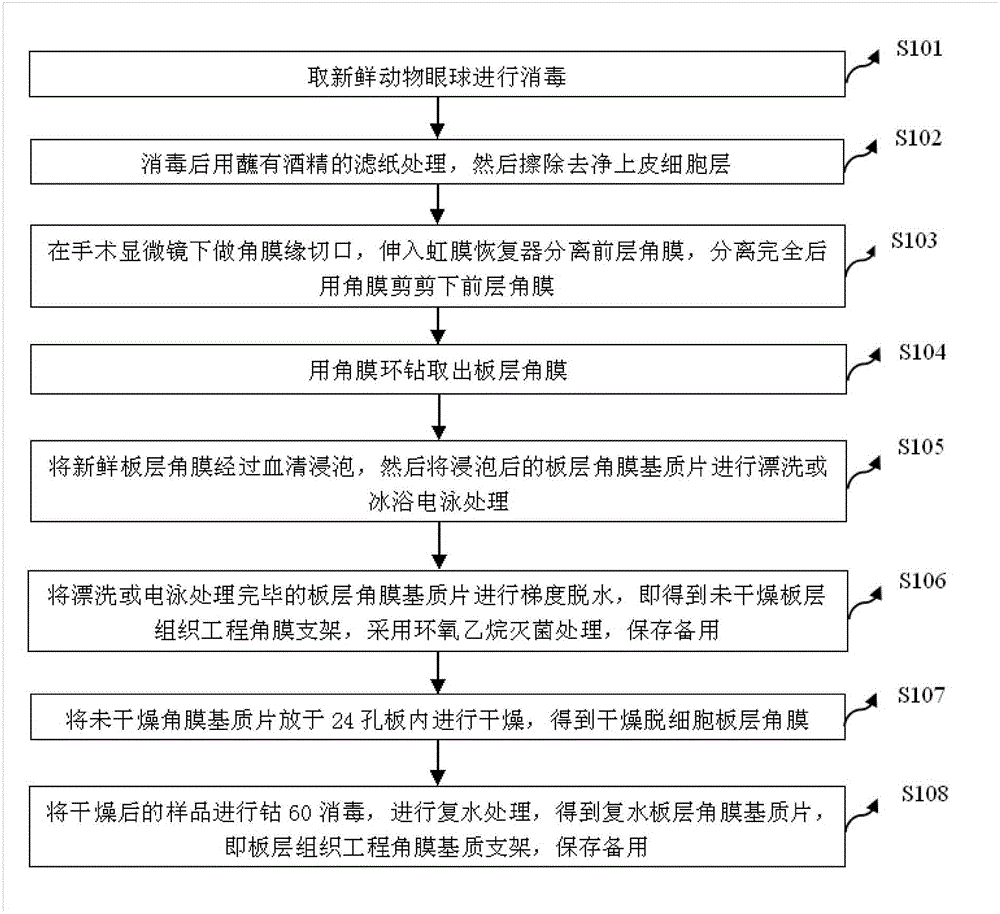

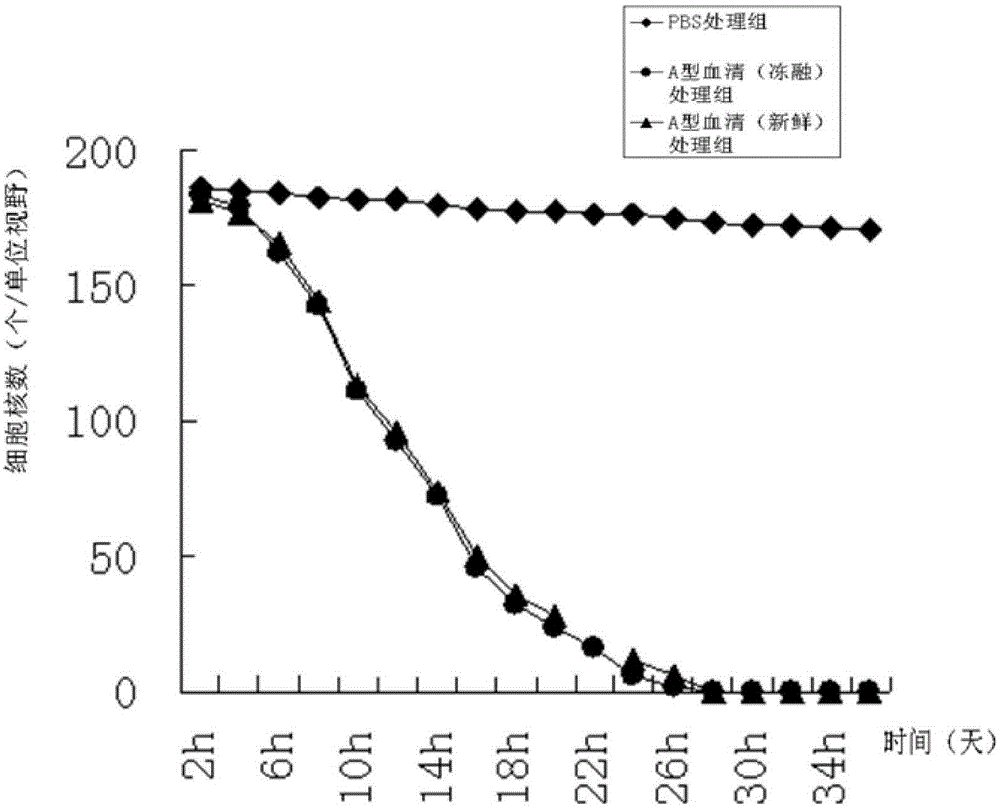

Method for preparing decellularized lamellar cornea matrix sheet

InactiveCN104645415AThe production process is simple and reliableShorten the timeProsthesisAnterior corneaEthylene Oxide Sterilization

The invention discloses a method for preparing a decellularized lamellar cornea matrix sheet. The method comprises the steps of disinfecting a fresh animal eyeball; treating with filter paper dipped with alcohol after disinfecting, and then erasing an epithelial cell layer; incising the corneal limbus under an operation microscope, stretching into an iris restorer to separate the anterior cornea, and then shearing the anterior cornea with corneal scissors; drilling the lamellar cornea with a corneal annulus; soaking the fresh lamellar cornea into serum, and then rinsing or performing ice-bath electrophoresis treatment; performing gradient dehydration after the treatment to obtain a non-dried lamellar tissue engineering corneal frame, sterilizing with ethylene oxide, and preserving for later use; drying the non-dried cornea matrix sheet in a 24-pore plate to obtain dried decellularized lamellar cornea; and sterilizing the dried sample with cobalt 60, and performing rehydration treatment to obtain a rehydrated lamellar cornea matrix sheet. The obtained cornea matrix sheet is high in transparency, low in structural destroy, good in biocompatibility, close to fresh cornea in performance and thorough in decellularization.

Owner:南昌大学第一附属医院 +1

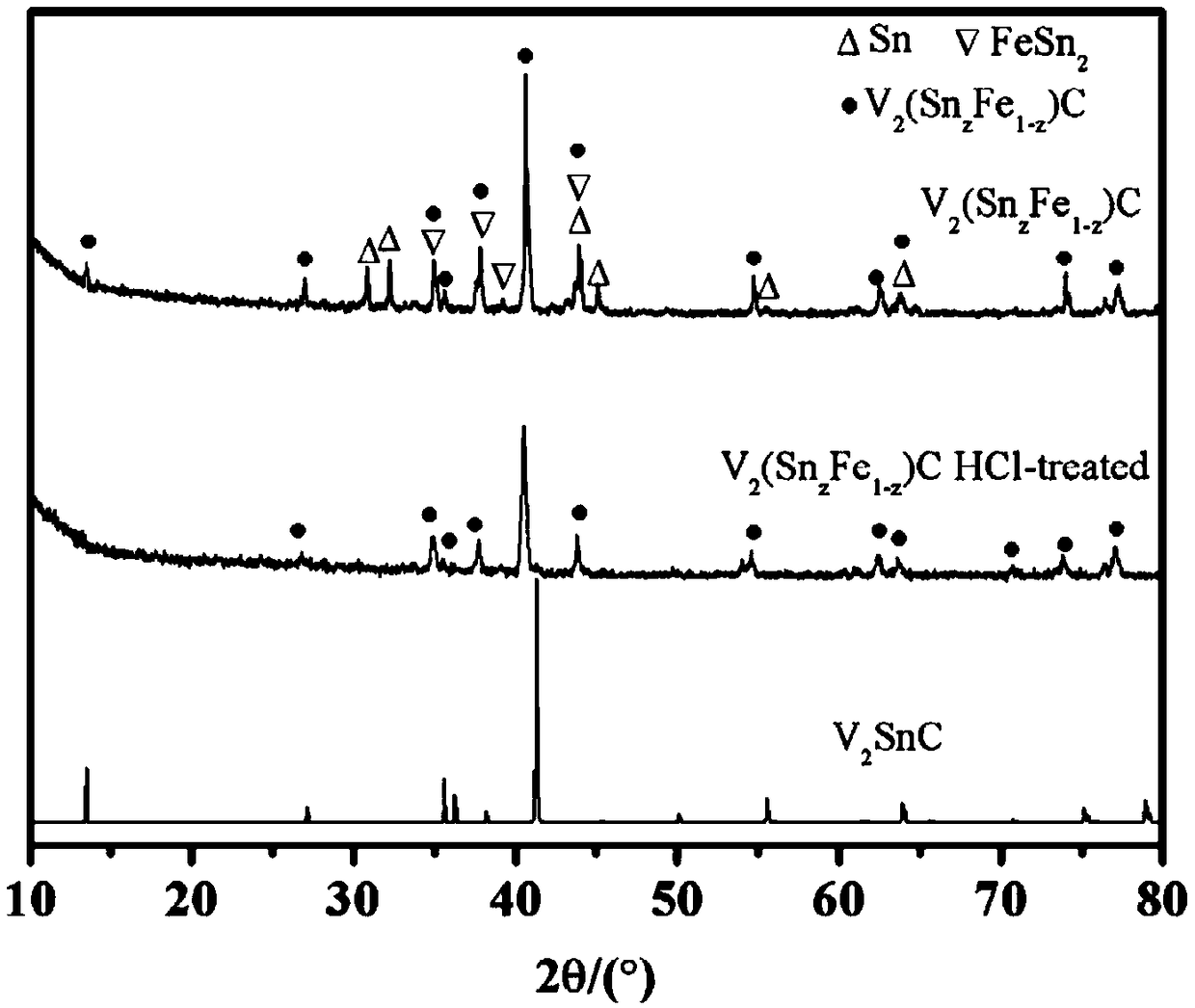

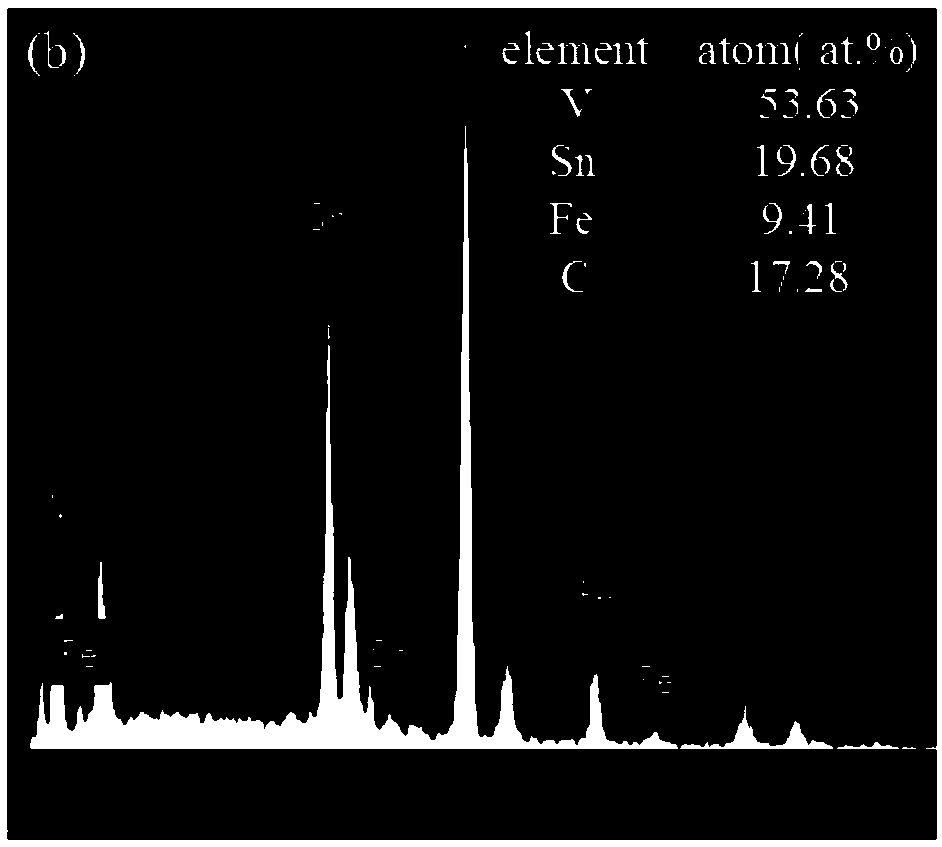

Ternary layered MAX phase material with A site as magnetic element as well as preparation method and application thereof

ActiveCN108922705ASimple manufacturing methodUniversalInorganic material magnetismInductances/transformers/magnets manufactureMagnetic storageSpins

The invention discloses a ternary layered MAX phase material with A site as a magnetic element as well as a preparation method and an application thereof. The molecular formula of the ternary layeredMAX phase material is Mn+1 (AzA'1-z) Xn, wherein M is selected from any one or a group of any two kinds of IIIB, IVB, VB, and VIB; A is selected from any one or a group of any two kinds of IVA, VA andVIA; A' is a magnetic element; X is any one or a combination of any two of C and N elements; z is greater than 0 and less than 1; and n is 1, 2, 3 or 4. The ternary layered MAX phase material has a hexagonal crystal structure, and the space group is P63 / mmc; and the cells are formed by atomic alternate stacking of an Mn+1Xn unit and an (AxA'1-x) layer. The ternary layered MAX phase material withA site as the magnetic element has a potential application prospect in the fields of catalysis, wave absorption, spin electronics, energy storage, magnetic refrigeration or magnetic storage and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

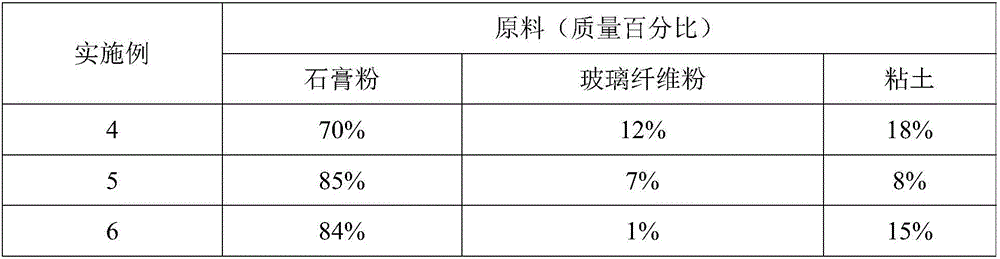

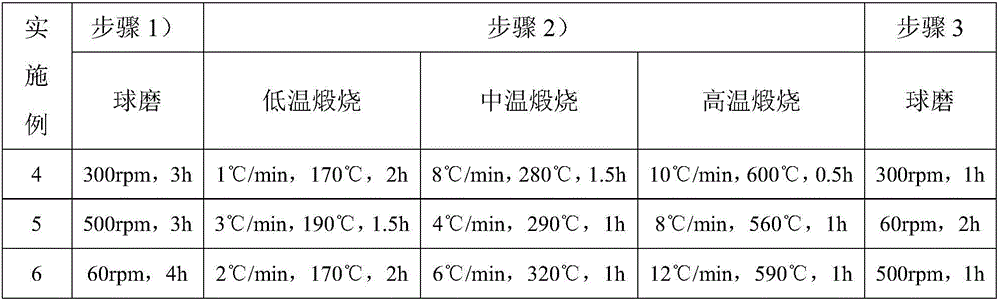

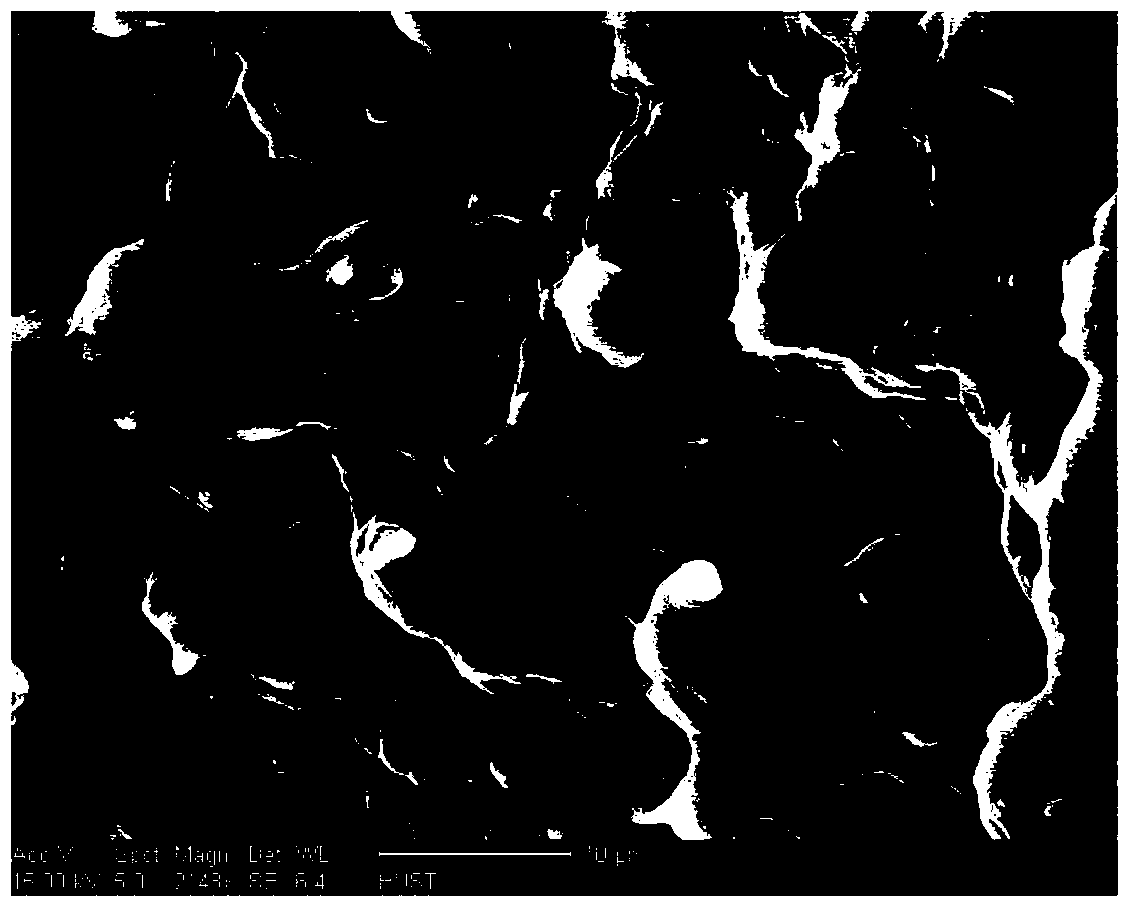

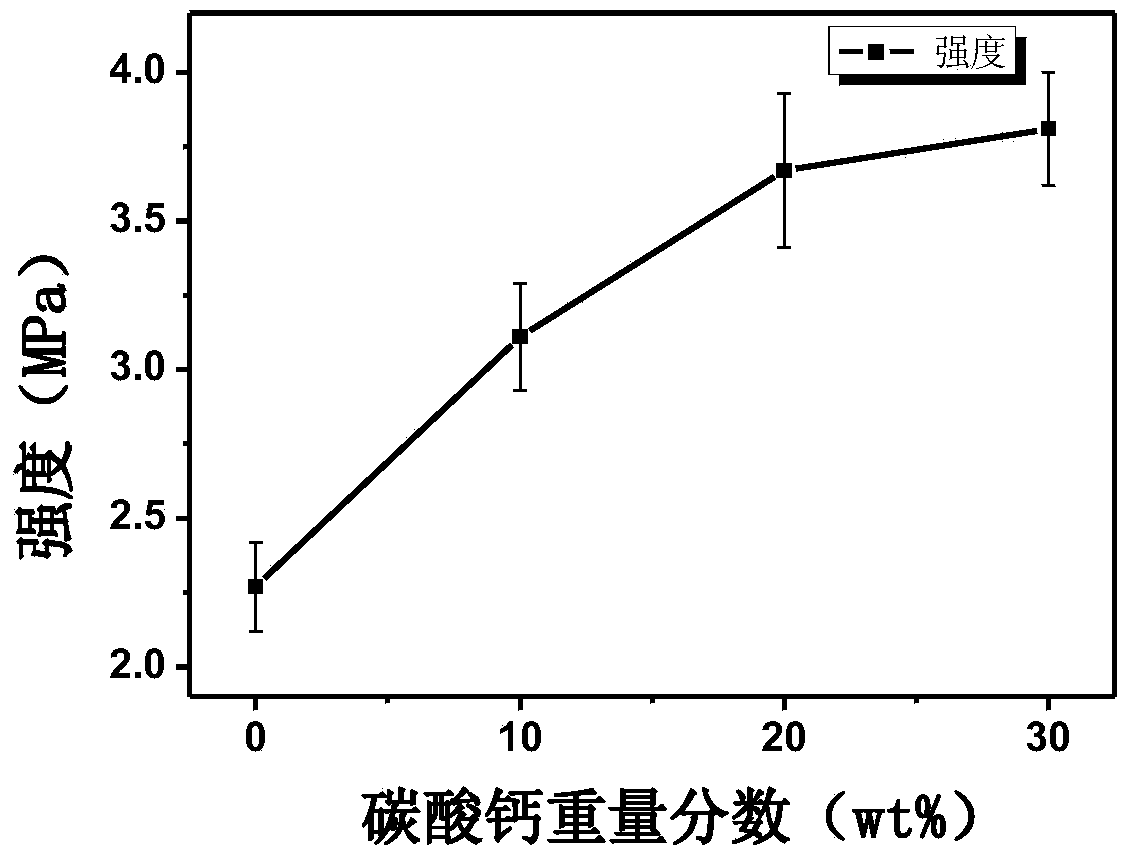

Binding agent, preparation method and grinding wheel

The invention relates to a binding agent, a preparation method and a grinding wheel, and belongs to the technical field of abrasives and grinding tools. The binding agent is mainly prepared from the following raw materials by mass percent: 70% to 85% of gypsum, 1% to 12% of glass fiber powder and 8% to 18% of clay. According to the binding agent, the raw materials coact with each other in a limited dosage proportion range, so that a compound high-temperature sintered product has relatively high strength, proper hardness and good plasticity; during preparation of the grinding wheel, the binding agent is mixed with water according to a suitable proportion, the forming speed is high, sintering is not carried out in the follow-up steps, and only natural drying or accelerated drying is required; sintering is not required, and the hardening speed is high, so that various problems like cracking and foaming occurring in traditional ceramic bond sintering are avoided; the binding agent is applicable to grinding wheels for low-speed and high-precision grinding, and the prepared grinding wheel is sharp and is high in grinding efficiency; the binding agent is applicable to various abrasives, the holding force for the abrasives is good, and the binding agent has universality; and the raw materials of the binding agent are easy to obtain, the cost is low, and the binding agent is applicable to large-scale industrial production.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

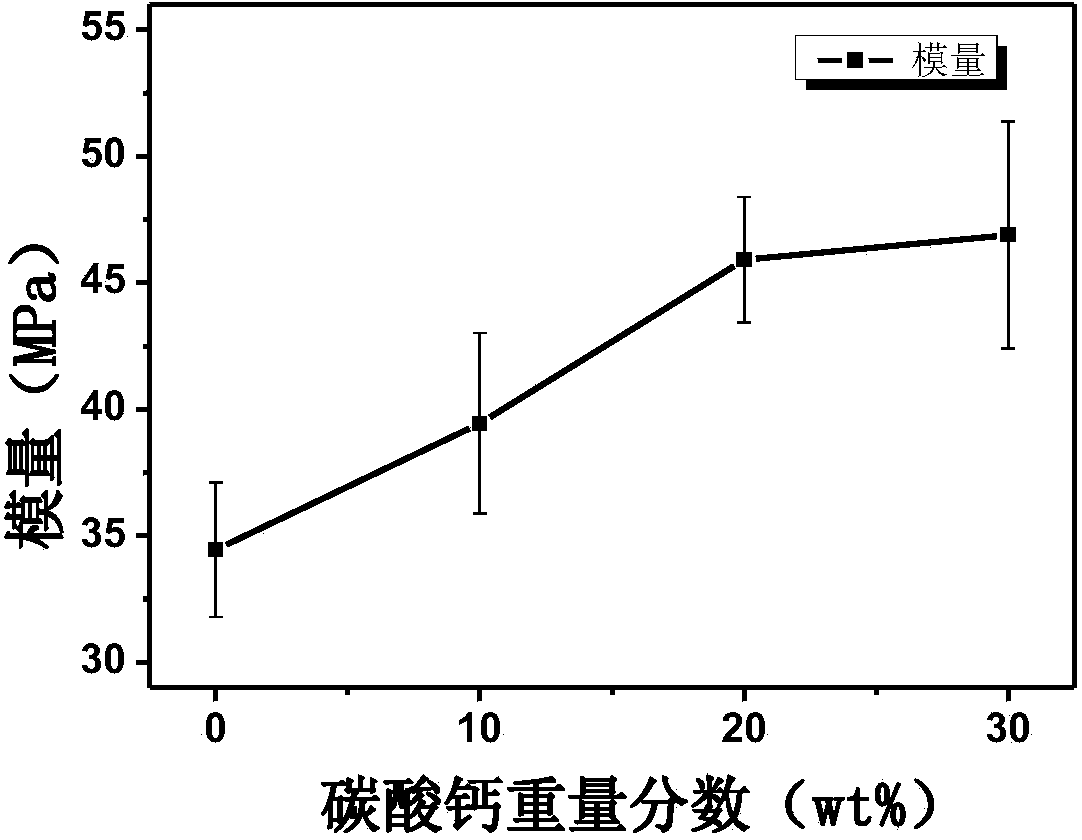

Thermoplastic cellulose composite material and preparation method thereof

The invention discloses a p thermoplastic cellulose composite material and a preparation method thereof. The composite material comprises the following components in percentage by mass: 0.03-28.57% of functional filler, 14.29-69.98% of ionic liquid and the balance of cellulose. The ionic liquid is used as a plasticizer, and can destroy the intermolecular hydrogen bond of the cellulose and increase the free volume, thereby plastifying the cellulose. The preparation method comprises the following steps: plastifying the cellulose by using the ionic liquid as the plasticizer to obtain an ionic liquid-cellulose base material, and carrying out melt compounding with the functional filler. The thermoplastic cellulose composite material can be formed and processed repeatedly, and has high adjustability in selection and proportioning of the composite filler. Compared with the prior art, the method has the advantages of simple technique and high production efficiency, is more suitable for the industrialized production mode, overcomes the defect of single processing means and product form in the past cellulosic material, and widens the application range of the cellulosic material.

Owner:ZONYA PRINTING & PACKAGING CO LTD

Polyurethane-based black polymeric dye, preparing method and application

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Production method for chemically coloring low-chromium stainless steel into black

InactiveCN103031552AAchieve corrosion resistanceHigh in ironMetallic material coating processesHigh concentrationHigh energy

The invention discloses a production method for chemically coloring low-chromium stainless steel into black. In the conventional stainless steel chemical coloring, a chromium-iron alloy of which the chromium content is over 13 percent is selected mostly, and a process for using high-temperature and high-concentration chromic acid and sulfuric acid is adopted, so that defects on the aspects of the performance of a black film and color control and the defects of high energy consumption, high pollution, high cost and the like exist. Stainless steel of which the chromium content is 11.7-13 percent is taken as a substrate material, and a chemical coloring liquid of a low-temperature, low-concentration and nontoxic oxidant is adopted; and a black oxide film which is dense on the appearance and has luster is formed on the surface of low-chromium stainless steel, and a corrosion resisting effect which is the same as that of high-chromium stainless steel is achieved.

Owner:张晓波

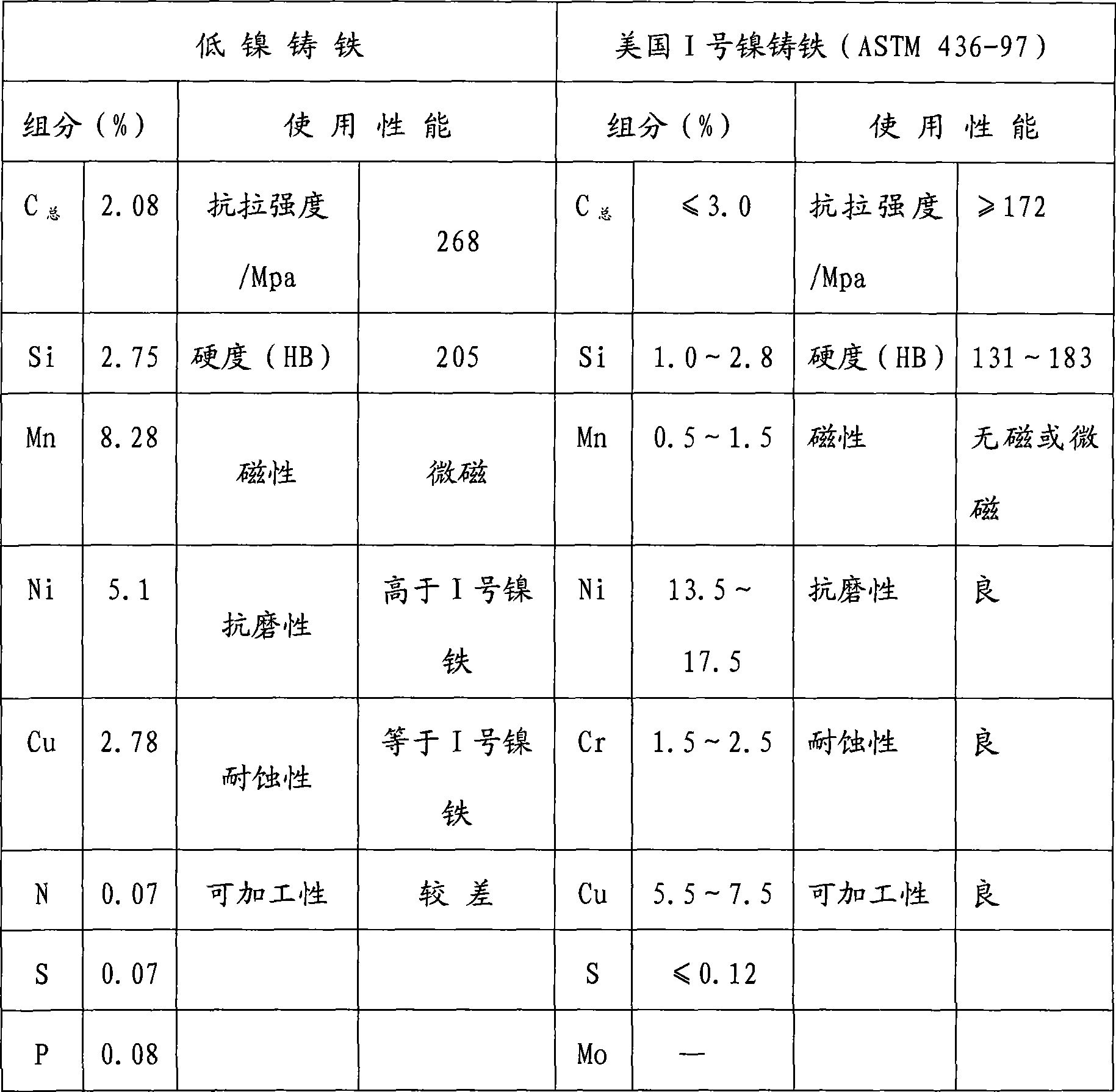

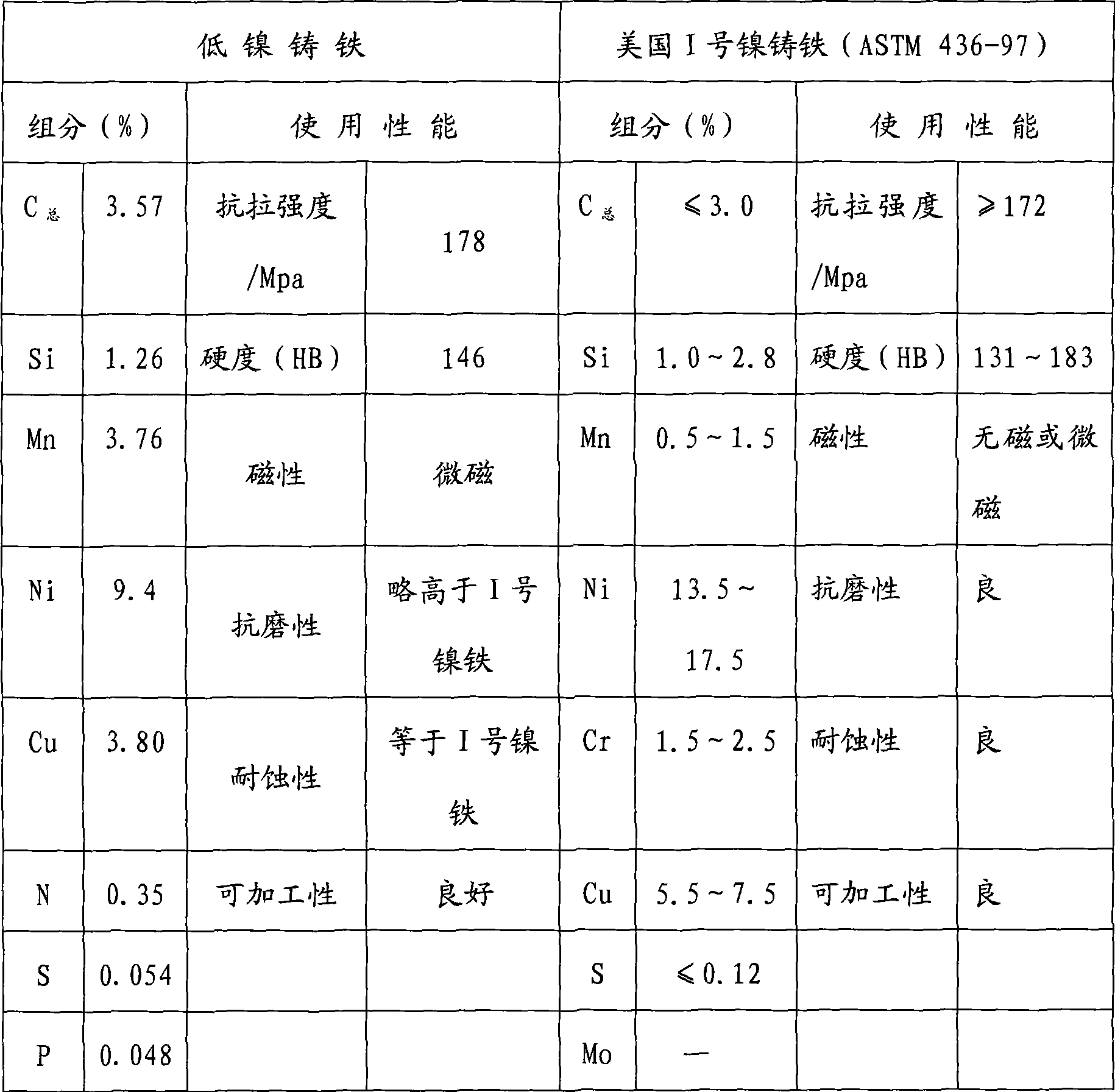

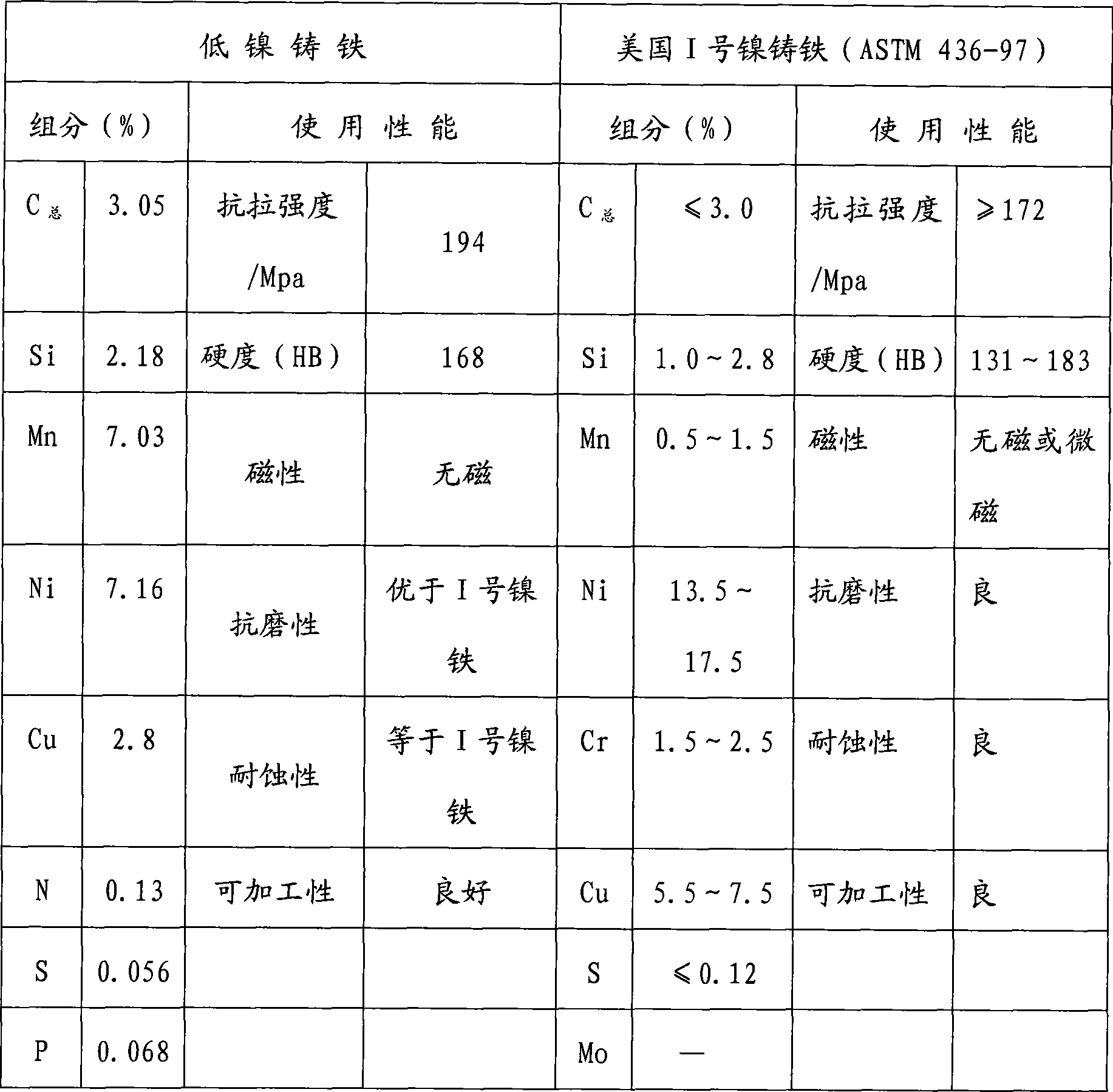

Low nickel cast iron and preparation method thereof and use thereof in impeller

ActiveCN101418411AImprove mechanical propertiesComprehensive mechanical properties such as high hardnessMolten metal pouring equipmentsPump componentsImpellerIntermediate frequency

The invention discloses a low-nickel cast iron material, which comprises the following compositions in weight percentage: 2.0 to 3.6 percent of C, 1.0 to 2.8 percent of Si, 3 to 10 percent of Mn, 3 to 10 percent of Ni, 2 to 5 percent of Cu, 0.05 to 0.5 percent of N, and the balance being iron. The invention discloses a manufacturing method for low-nickel cast iron at the same time, which comprises the following steps: a, preparing a charging material; b, charging the charging material into an intermediate frequency electric furnace to melt, covering the charging material by perlite after the charging material is totally melted; and c, when the charging material is heated to above 1,650 DEG C, removing slag and discharging molten iron; and controlling the cast molten iron at a temperature of between 1,400 and 1,550 DEG C. The invention also discloses application of the low-nickel cast iron to a guide impeller. Combination property and abrasion resistance of the low-nickel cast iron are higher than those of American No. I nickel cast iron, and metallurgical structure and corrosion resistance of the low-nickel cast iron accord with those of the American No. I nickel cast iron.

Owner:ZHEJIANG ZHENXING PETROCHEM MACHINERY

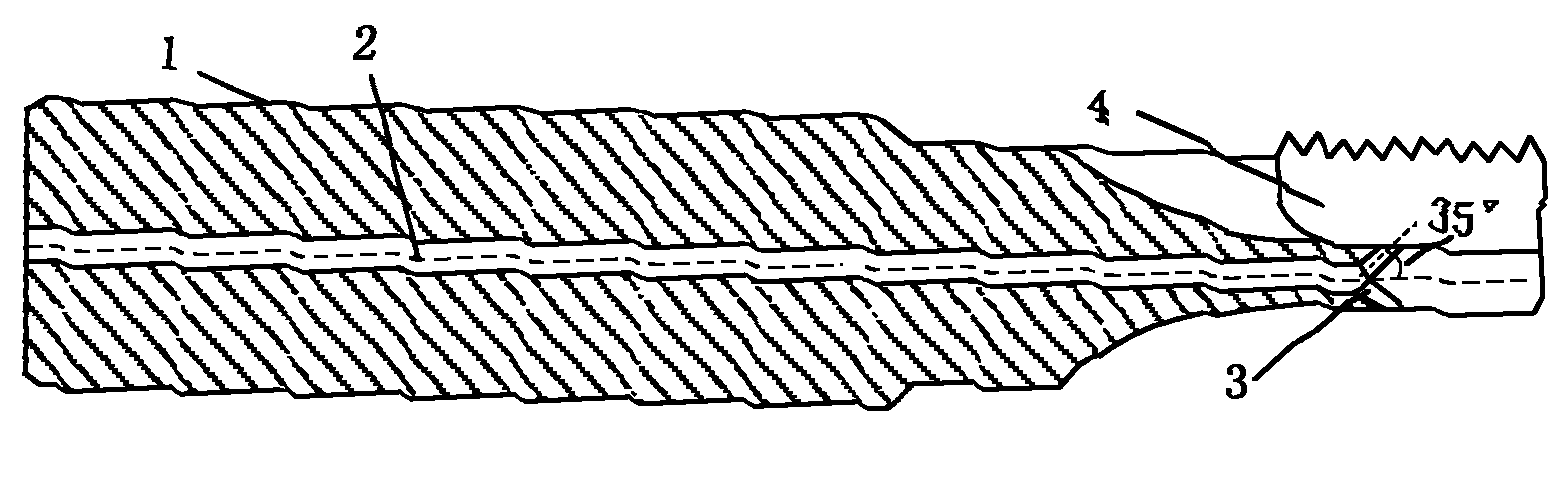

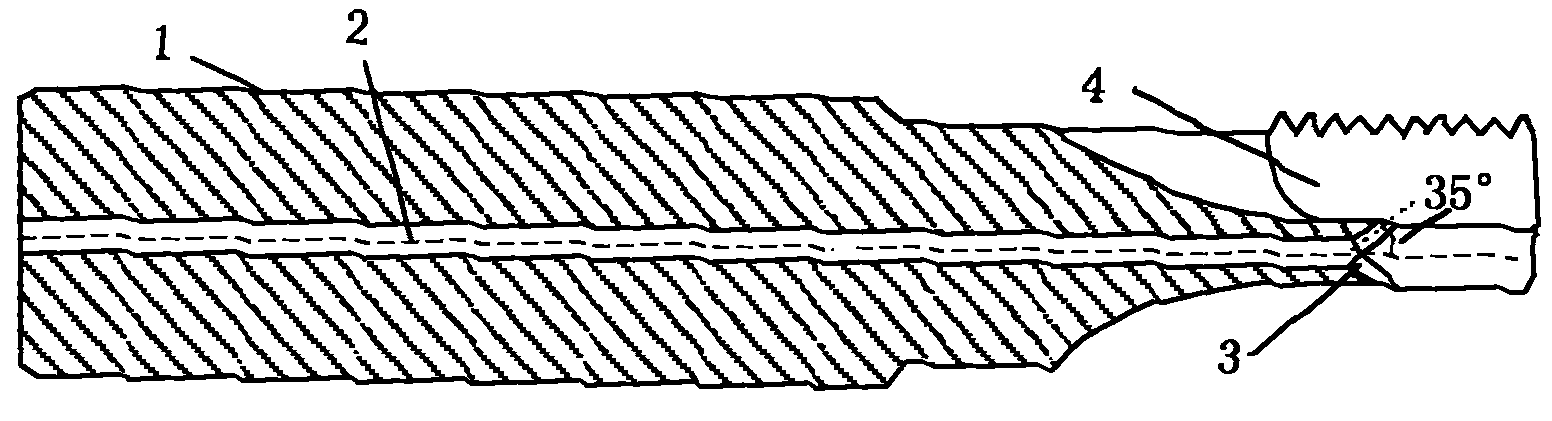

Manufacturing method of inner bore cooling polycrystalline diamond (PCD) thread high-speed forming cutter

The invention relates to a manufacturing method of an inner bore cooling polycrystalline diamond (PCD) thread high-speed forming cutter, belonging to the technical field of machining. The method comprises the following steps: carrying out abrasive machining on a hard alloy cutter body, punching cooling bores in the hard alloy cutter body, carrying out PCD chip welding, and finally carrying out wire cutting on the PCD chip by using a slow wire cutting machine, thereby obtaining the cutter. The invention realizes high-efficiency precision manufacturing technique of a hard alloy straight-shank straight-channel welded-type inner bore cooling PCD thread high-speed forming cutter.

Owner:上海工具厂有限公司 +1

Aerated concrete block and preparation method thereof

InactiveCN101913903ALose weightSmall sizeCeramic shaping apparatusCeramicwareSteam pressurePolymer science

The invention discloses an aerated concrete block and a preparation method thereof. The aerated concrete block is prepared from the following components: 250-320kg of cement, 350-400kg of lime, 1400-1600kg of silica sands, 1.45-1.6kg of aluminium powder, 0.195-0.205kg of foam stabilizers and water. The preparation method comprises the following steps: raw material preparing, metering, stirring, pouring into molds, standing and procuring, demolding, lifting to a cutting part for cutting, steam pressure curing in a kettle and finished product warehousing. The block has the advantages of light weight, good thermal insulation property, processability, convenient construction, wide raw material sources, high preparation efficiency, low preparation energy consumption, environment-friendliness and good fireproofing and soundproofing properties, specifically, the bulk density of the block is 500-700kg / m3, which is equivalent to 1 / 3 of the bulk density of the clay bricks; the block is provided with plentiful pores and micropores inside, thus having good thermal insulation property; the block dispenses with coarse aggregates, thus having good processability, being capable of being sawed, planed, drilled and stapled, being capable of being bonded by bonding materials and providing favorable conditions for building construction.

Owner:舟山市宇锦新型墙体材料有限公司

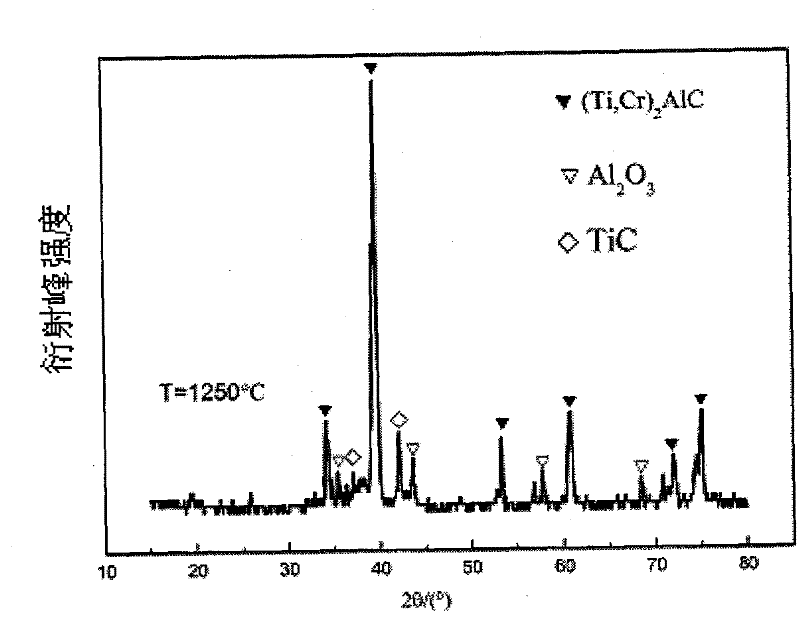

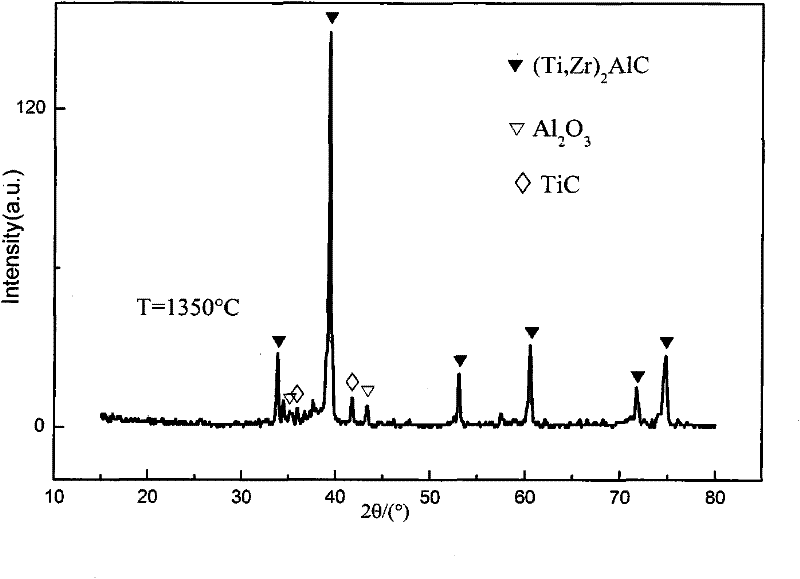

(Ti, Cr) 2AlC solid solution composite material and preparation method thereof

InactiveCN102181766AThe ingredients are highly adjustableLower firing temperatureGeneration processSolid solution strengthening

The invention discloses a (Ti, Cr) 2AlC solid solution composite material and a preparation method thereof. The preparation method comprises the following steps of: performing hot pressed sintering process on Ti power accounting for 40.92-70.11% of the total weight, Al power accounting for 20.15-24.02% of the total weight, C power accounting for 6.99-8.85% of the total weight and Cr2O3 power accounting for 0.88-28.07% of the total weight; and self-generating a granular reinforcement phase in the generation process of a substrate phase by using thermit reaction so as to prepare an aplitic composite material of which the substrate phase (Ti, Cr)2AlC is reinforced with an Al2O3 disperse phase; and performing solid solution strengthening on the substrate phase by using Cr generated by the reaction. Since the material has high composition adjustability, low firing temperature, even and dense structure, lower cost and excellent mechanical property, the application scope of the composite material is widened; in addition, by using the method, the firing temperature and the hot pressing pressure are reduced and micritization of crystals is realized.

Owner:陕西鑫汇新能源科技开发有限公司

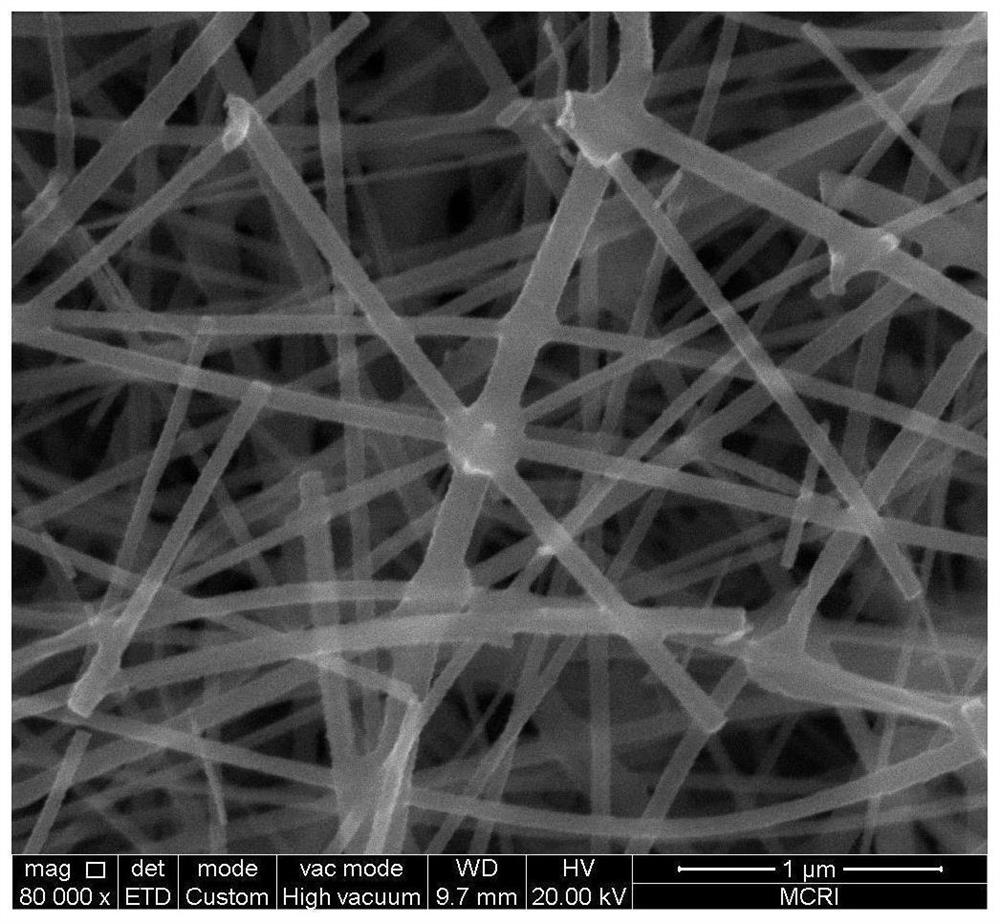

Lightweight high-strength elastic ceramic and preparation method thereof

The invention discloses a lightweight high-strength elastic ceramic and a preparation method thereof, and belongs to the technical field of porous ceramic preparation, the lightweight high-strength elastic ceramic is formed by bonding ceramic nanowires to form a continuous porous layered network, and the lightweight high-strength elastic ceramic is prepared by taking ceramic nanowire aerogel as a raw material, the preparation method comprises the following steps: forming a layered structure, placing ceramic nanowire aerogel in a mold, and carrying out axial compression; welding the ceramic nanowires, and performing heat preservation treatment in the high-temperature oxygen-free environment, wherein the ceramic nanowires making contact with one another can be welded together through oxide layers on the surfaces of the nanowires so that the lightweight high-strength elastic ceramic is obtained.

Owner:XI AN JIAOTONG UNIV

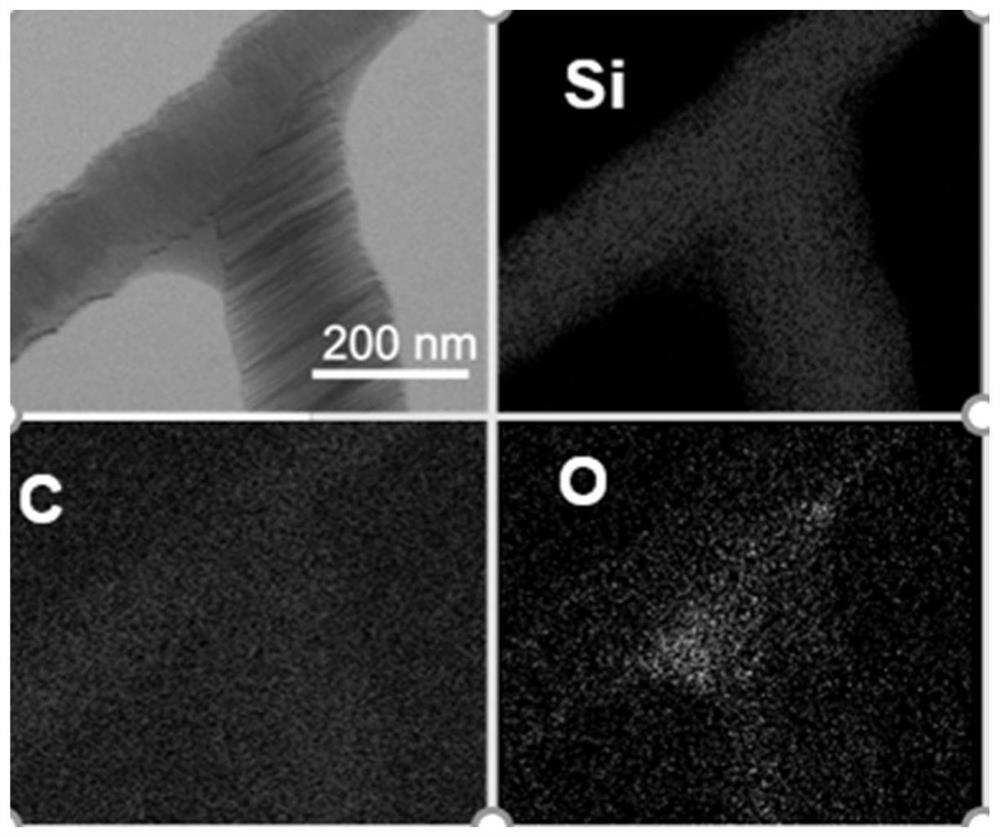

(Ti, Zr)2AlC/Al2O3 solid solution composite material and preparation method thereof

ActiveCN102174680AThe ingredients are highly adjustableImprove adjustabilitySolid solution strengtheningMechanical property

The invention discloses a (Ti, Zr)2AlC / Al2O3 solid solution composite material and a preparation method thereof. The method comprises the following steps of: performing a hot-press sintering process on 39.38 to 70.08 weight percent of Ti powder, 20.11 to 22.85 weight percent of Al powder, 6.37 to 8.84 weight percent of C powder and 0.97 to 31.41 weight percent of ZrO2 powder; automatically generating a particle wild phase by using a thermit reaction in the process of generating a matrix phase to obtain an Al2O3 dispersed phase reinforced matrix phase Ti2AlC fine crystal composite material; and performing solid solution strengthening on a matrix by using Zr generated by the reaction. The material has high component adjustability, a low sintering temperature, a uniform and compact structure, lower cost and a high mechanical property, so that the application range of the composite material is widened; in addition, by the method, sintering temperatures and hot-pressing pressure are reduced, and crystal grain micritization is realized in the quick sintering process.

Owner:PHENOM INNOVATIONS XIAN CO LTD

Biodegradable vinasse protein film as well as preparation method and application thereof

The invention relates to a biodegradable vinasse protein film as well as a preparation method and application thereof, and the vinasse protein film is obtained by processing vinasse protein modified by protein through a film forming technology, the vinasse protein modified by the protein comprises vinasse protein, a plasticizer, a cross-linking agent, a chain extender, a dihydric alcohol oligomer and a water repellent agent. The invention further provides a preparation method and application of the biodegradable vinasse protein film. By modifying the vinasse isolated protein, the vinasse protein not only has the machinability of traditional plastics, but also improves the water resistance and mechanical strength of the vinasse protein film, so that the vinasse protein film better conforms to the characteristics of a film packaging material, is used for replacing a traditional non-degradable plastic film, and helps to solve the pollution problem of the traditional plastics; meanwhile, the application range of the vinasse is also expanded.

Owner:杭州靡特洛新材料科技有限公司

Method for preparing quartz composite material by electrophoretic deposition of silica sol

The invention discloses a method for preparing a quartz composite material by the electrophoretic deposition of silica sol. The method comprises the following steps: (1) weaving quartz fibers to form an integral fabric of an appointed shape, and removing and drying impregnating compound on the surface of fabric fibers; (2) in an insulated container, putting quartz fiber fabrics between an anode and a cathode, and connecting with a direct-current power supply; (3) injecting the silica sol into the insulated container to enable the sol to completely submerge electrodes and fabrics; (4) turning on the direct-current power supply, regulating voltage, carrying out the deposition of silica sol on the fabrics, extracting clear liquid according to the size of a construction member, and filling the sol; (5) taking out the fabrics subjected to electrophoretic deposition, drying, sintering, and forming a quartz fiber enhanced quartz ceramic composite material. The method has the advantages of simple and reliable operation, short period and low cost, and the compactness and the evenness of the material can be improved.

Owner:曹原

High temperature resistant low-deformation medical TPE (thermoplastic elastomer) injection molding rubber plug material and preparation method thereof

The invention relates to a high temperature resistant low-deformation medical TPE (thermoplastic elastomer) injection molding rubber plug material and a preparation method thereof. The material mainly contains the following components in parts by weight: 20-150 parts of SEBS, 20-120 parts of at least one of SEPS and SEEPS, 20-200 parts of white oil, 20-160 parts of reinforced resin and 10-200 parts of filler. The material has the beneficial effects that the elasticity and strength of the new copolymer are greatly improved by blending SEBS, SEPS and SEEPS; the temperature and stress deformation resistance of the product system is improved by using the high molecular weight raw materials; the microscopic interlayer spacing of the product molecules is changed via the intercalation effect of montmorillonite, thus not only improving the original surface rigidity, creep resistance, acid-base resistance and dimensional stability of the filler system, but also improving the compatibility of the whole system and improving the high temperature resistance and low deformation performance of the product.

Owner:济南泰瑞丰高分子新材料有限公司

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266BGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsEpoxyHeavy duty

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

Polyurethane based fluorescent whitening agent and preparation method thereof

The invention discloses a polyurethane based fluorescent whitening agent and a preparation method thereof. The preparation method includes the steps that polymer polyalcohol is heated, vacuum dewatering is conducted for 1-2 hours, nitrogen gas is introduced for cooling, and diisocyanate, solvent and a catalyst are added for a reaction; then, an organic small molecular fluorescent whitening agent body is added, a reaction is conducted, and polyurethane prepolymer with the fluorescent whitening agent body is prepared; water-based chain extender is added into the polyurethane prepolymer, and a reaction is conducted; then, solvent is added to dilute the mixture to certain viscosity, a salt-forming agent is added, and a polyurethane ionomer is formed; the polyurethane ionomer is transferred into an emulsification reactor, then emulgator and water are added, then solvent removal is conducted, and water-based polyurethane based fluorescent whitening emulsion is obtained. The polyurethane based fluorescent whitening agent has the advantages of being high in fluorescence quantum yield, resistant to light, resistant to heat, resistant to washing, resistant to wear, resistant to migration, resistant to wet processing, prone to film formation, capable of being processed and the like and further has the advantages of being good in whitening effect, convenient to use, low in cost, free of toxin, environmentally friendly and the like.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

(Ti, Nb) 3AlC2/Al2O3 solid solution composite material and preparation method thereof

ActiveCN102041425ASynthesis temperature is lowImprove performanceSolid solution strengtheningMechanical property

The invention discloses a (Ti, Nb) 3AlC2 / Al2O3 solid solution composite material and a preparation method thereof. The preparation method comprises the following steps: hot pressing and sintering the following materials in percentage by weight: 45.87-72.95% of Ti powder, 14.02-19.10% of Al powder, 9.23-12.25% of C powder and 0.78-25.81% of Nb2O5 powder, wherein a particle wild phase grows in the matrix phase generating process via thermit reaction, a fine crystal composite material of Al2O3 dispersed phase strengthened matrix phase Ti3AlC2 is prepared, and Nb generated by the reaction is usedfor carrying out solid solution strengthening on the matrix. Because the material ingredients have big adjustability, low firing temperature, even and compact structure, lower cost and excellent mechanical property, the application range of the composite material is expanded. In addition, the method lowers the firing temperature and the hot-press pressure and realizes crystalline grain micritization in the quick firing process.

Owner:PHENOM INNOVATIONS XIAN CO LTD

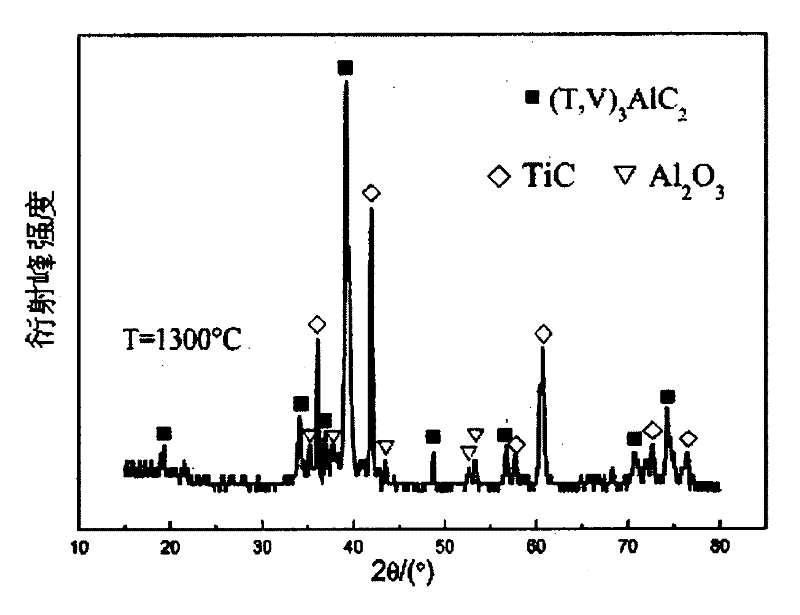

(Ti, V)3AlC2/Al2O3 solid solution composite material and preparation method thereof

InactiveCN102181769AThe ingredients are highly adjustableLower firing temperatureSolid solution strengtheningMechanical property

The invention discloses a (Ti, V)3AlC2 / Al2O3 solid solution composite material and a preparation method thereof. The preparation method comprises the following steps of: performing a hot pressed sintering process on 51.88 to 73.14 weight percent of Ti powder, 14.05 to 20.23 weight percent of Al powder, 10.23 to 12.28 weight percent of C powder and 0.53 to 17.66 weight percent of V2O5 powder; automatically generating a particle reinforced phase in the process of generating a matrix phase through a thermit reaction to prepare a fine crystal composite material of Al2O3 dispersed phase reinforced matrix phase Ti3AlC2; and performing solid solution strengthening on the matrix phase by using V generated by a reaction. The material has high component adjustability, a low firing temperature, a uniform and compact structure, relatively low cost and a high mechanical property, and the application range of the composite material is widened; in addition, the firing temperature and hot-pressing pressure are reduced and the sitallization of crystal grains is realized during fast firing by the method.

Owner:SHAANXI UNIV OF SCI & TECH

Highly tenacious soluble composite material salt core and production method

InactiveCN101269401BHigh strengthImprove plasticityFoundry mouldsMould handling/dressing devicesFiberWater soluble

Owner:XIAN KANGBO NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com