(Ti, Cr) 2AlC solid solution composite material and preparation method thereof

A composite material and solid solution technology, which is applied in the field of composite material manufacturing, can solve problems such as high synthesis temperature, high reaction temperature, and no solid solution modification of the matrix phase, and achieve uniform and dense structure, excellent mechanical properties, and broaden the application range. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

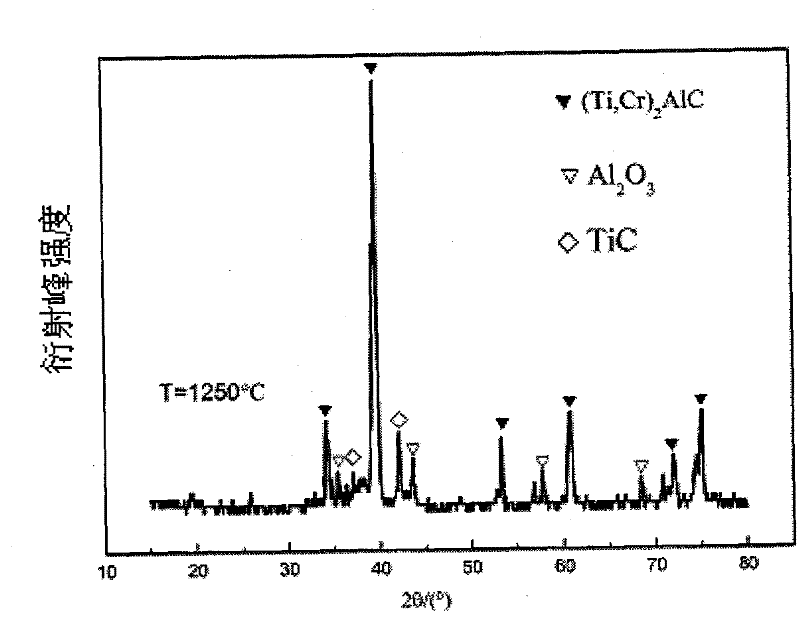

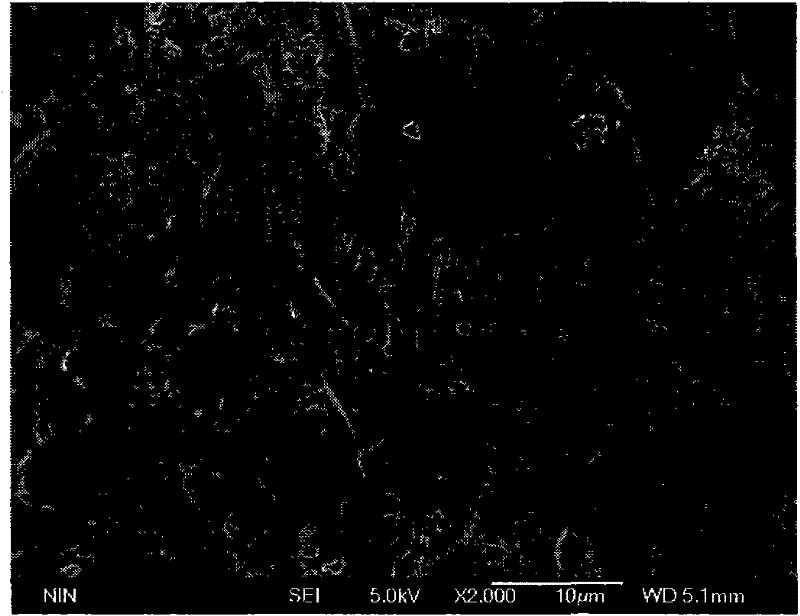

Embodiment 1

[0020] A (Ti, Cr) 2 AlC solid solution composite material, the raw material composition is: 270 mesh Ti powder accounts for 66.18% of the total weight, 200 mesh Al powder accounts for 22.22% of the total weight, 1200 mesh C powder accounts for 8.11% of the total weight and Cr 2 o 3 Powder accounted for 3.49% of the total weight.

[0021] A (Ti, Cr) 2 The preparation method of AlC solid solution composite material, the steps are as follows:

[0022] 1. First, the purity is greater than or equal to 99%, and the fineness is 270 mesh metal Ti powder, 200 mesh Al powder, 1200 mesh C powder and metal oxide Cr 2 o 3 Weighing according to the following proportions, Ti powder accounts for 66.18% of the total weight, Al powder accounts for 22.22% of the total weight, C powder accounts for 8.11% of the total weight, Cr 2 o 3 Powder accounts for 3.49% of the total weight;

[0023] Two, the batching in the step 1 is put into the aluminum oxide ball mill jar and carry out mixed ball ...

Embodiment 2

[0030] A (Ti, Cr) 2 AlC solid solution composite material, the raw material composition is: 270 mesh Ti powder accounts for 62.44% of the total weight, 200 mesh Al powder accounts for 22.74% of the total weight, 1200 mesh C powder accounts for 7.88% of the total weight and Cr 2 o 3 Powder accounts for 6.94% of the total weight.

[0031] A (Ti, Cr) 2 The preparation method of AlC solid solution composite material, the steps are as follows:

[0032] 1. First, the purity is greater than or equal to 99%, and the fineness is 270 mesh metal Ti powder, 200 mesh Al powder, 1200 mesh C powder and metal oxide Cr 2 o 3 Weighing according to the following proportions, Ti powder accounts for 62.44% of the total weight, Al powder accounts for 22.74% of the total weight, C powder accounts for 7.88% of the total weight, Cr 2 o 3 Powder accounts for 6.94% of the total weight;

[0033] Two, the batching in the step 1 is put into the aluminum oxide ball mill jar and carry out mixed ball m...

Embodiment 3

[0040] A (Ti, Cr) 2 AlC solid solution composite material, the raw material composition is: 270 mesh Ti powder accounts for 55.09% of the total weight, 200 mesh Al powder accounts for 23.78% of the total weight, 1200 mesh C powder accounts for 7.42% of the total weight and Cr 2 o 3 Powder accounts for 13.71% of the total weight.

[0041] A (Ti, Cr) 2 The preparation method of AlC solid solution composite material, the steps are as follows:

[0042] 1. First, the purity is greater than or equal to 99%, and the fineness is 270 mesh metal Ti powder, 200 mesh Al powder, 1200 mesh C powder and metal oxide Cr 2 o 3 Weighing according to the following proportions, Ti powder accounts for 55.09% of the total weight, Al powder accounts for 23.78% of the total weight, C powder accounts for 7.42% of the total weight, Cr 2 o 3 Powder accounts for 13.71% of the total weight;

[0043] Two, the batching in the step 1 is put into the aluminum oxide ball mill jar and carry out mixed ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com