A preparation method of aluminum anode material for sustainable and stable hydrogen production

An aluminum anode and stable technology, which is applied in the field of preparation of aluminum anode materials for sustainable and stable hydrogen production, can solve the problems such as non-uniform shedding of corrosion products, low current efficiency of sacrificial anodes, segregation and dissolution of alloy components, and easy control of the synthesis process. , The effect of good hydrogen production rate and uniform and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

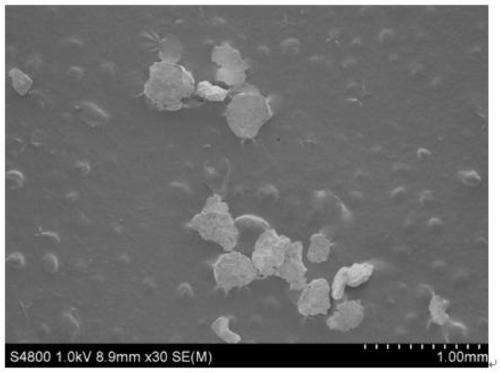

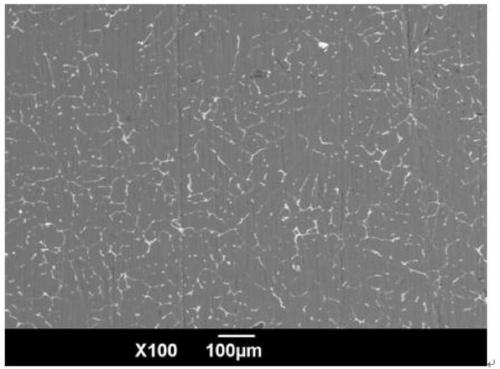

Image

Examples

Embodiment 1

[0018] Step 1: Synthesizing master alloy powders such as Al-10%Ga, Al-20%In, Al-10%Sn, Al-10%Mg by pre-synthesis method;

[0019] Step 2; the alloy powder synthesized in step 1 is by mass ratio 15% (Al-10%Ga), 30% (Al-20%In), 30% (Al-10%Sn), 25% (Al -10% Mg) are uniformly mixed, the mixture is put into a steel tank, and put into a planetary ball mill for mechanical alloying. The mass ratio of the material to the ball is set to 1:25, the ball milling speed is set to 400 rpm, and the ball milling time is set to 1 Hour, obtain alloy material;

[0020] Step 3: Send the alloy material after ball milling in step 2 into the preset product mold in the hot press for pressing, and press the mixture into a blank at a pressing pressure of 1.5Gpa and a pressing temperature of 850°C, and the heating rate is controlled 25°C / min. After pressing and forming, wait for the blank to cool to room temperature and then take out the finished product;

[0021] Step 4: Put the sintered blank into the...

Embodiment 2

[0023] Step 1: Synthesizing master alloy powders such as Al-10%Ga, Al-20%In, Al-10%Sn, Al-10%Mg by pre-synthesis method;

[0024] Step 2; the alloy powder synthesized in step 1 is by mass ratio 25% (Al-10%Ga), 25% (Al-20%In), 25% (Al-10%Sn), 25% (Al -10% Mg) are uniformly mixed, the mixture is put into a steel tank, and put into a planetary ball mill for mechanical alloying. The mass ratio of the material to the ball is set to 1:25, the ball milling speed is set to 400 rpm, and the ball milling time is set to 1 Hour, obtain alloy material;

[0025] Step 3: Send the alloy material after ball milling in step 2 into the preset product mold in the hot press for pressing, and press the mixed material into a blank at a pressing pressure of 1.5Gpa and a pressing temperature of 900°C, and the heating rate is controlled 30°C / min. After pressing and forming, wait for the blank to cool to room temperature and then take out the finished product;

[0026] Step 4: Put the sintered blank i...

Embodiment 3

[0028] Step 1: Synthesizing master alloy powders such as Al-10%Ga, Al-20%In, Al-10%Sn, Al-10%Mg by pre-synthesis method;

[0029] Step 2; the alloy powder synthesized in step 1 is 30% (Al-10%Ga), 20% (Al-20%In), 20% (Al-10%Sn), 30% (Al -10% Mg) are uniformly mixed, the mixture is put into a steel tank, and put into a planetary ball mill for mechanical alloying. The mass ratio of the material to the ball is set to 1:25, the ball milling speed is set to 400 rpm, and the ball milling time is set to 1 Hour, obtain alloy material;

[0030] Step 3: Send the alloy material after ball milling in step 2 into the preset product mold in the hot press for pressing, and press the mixed material into a blank at a pressing pressure of 1.5Gpa and a pressing temperature of 900°C, and the heating rate is controlled 25°C / min. After pressing and forming, wait for the blank to cool to room temperature and then take out the finished product;

[0031] Step 4: Put the sintered blank into the shapin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com