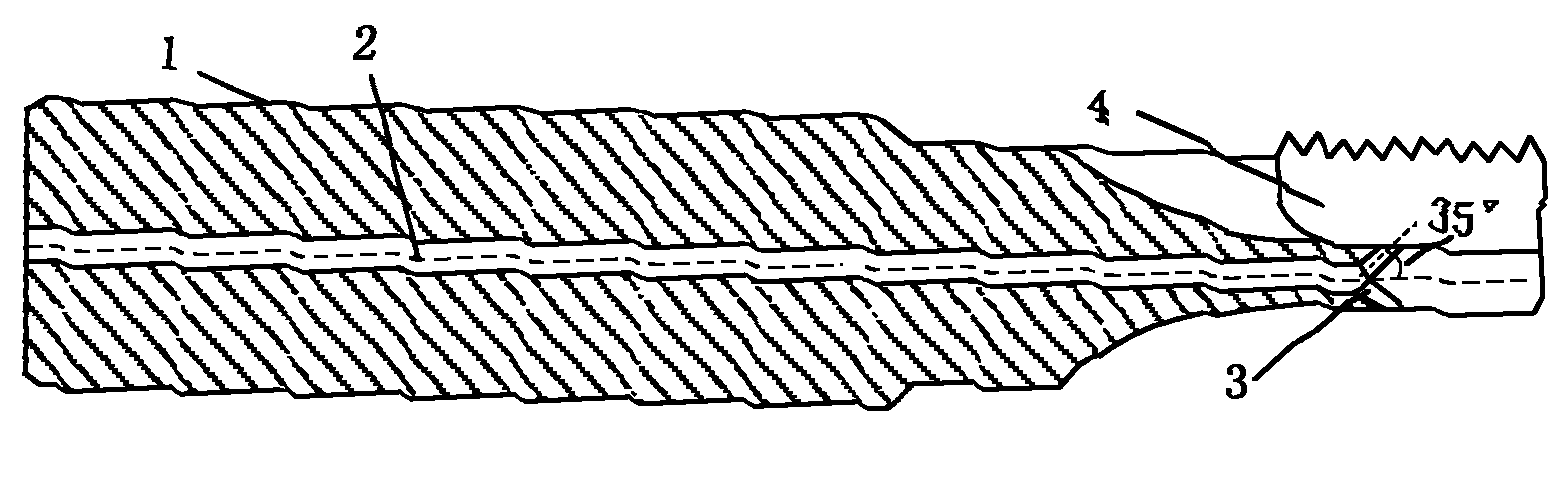

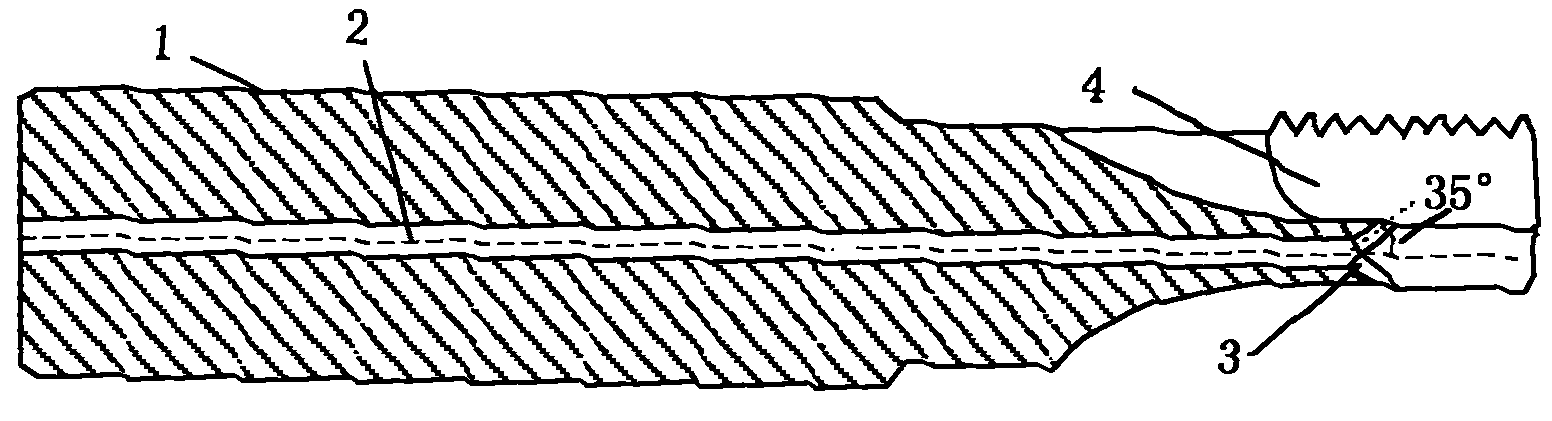

Manufacturing method of inner bore cooling polycrystalline diamond (PCD) thread high-speed forming cutter

A technology of polycrystalline diamond and forming tools, which is applied in the field of mechanical processing and can solve the problems of high cost and low efficiency of EDM

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0019] In the first step, the carbide blank is ground to the required size on the SAACK CNC tool grinding machine. Grinding parameters are: speed 10000r / min, feed 30mm / min.

[0020] In the second step, use an electric spark drilling machine to drill a main cooling hole with a diameter of 2mm in the center of the cutter body, and then drill two side cooling holes with a diameter of 1mm at the lower end of the main cooling hole. In order to ensure the design requirements of the tool, the processing parameters of the main cooling hole are: 19 pulses, 06 tubes, 30 servos, 1 capacitor, 5 pressure, 15-20 inter-electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com