Weather-resistant heavy-duty anticorrosive powder coating

A powder coating and heavy-duty anti-corrosion technology, applied in the field of coatings, can solve the problem that weather resistance and anti-corrosion properties cannot be combined, and achieve the effects of good anti-corrosion detection effect, excellent anti-corrosion resistance, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

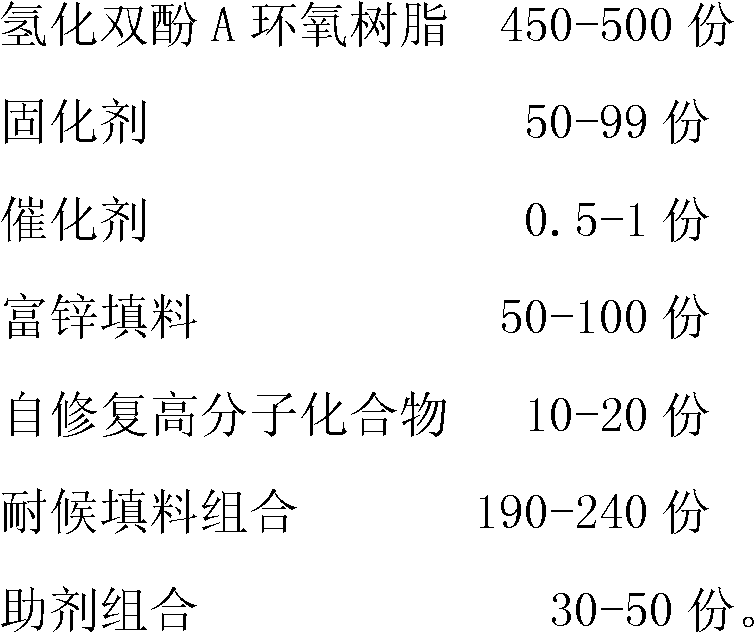

[0030] A weather-resistant heavy-duty anti-corrosion powder coating, its raw material composition and weight are:

[0031] 1. GEST-5080 hydrogenated bisphenol A epoxy resin 450 parts;

[0032] 2. 80 parts of amine curing agent;

[0033] 3. 0.5 parts of imidazole;

[0034] 4. 60 parts of conductive zinc powder;

[0035] 5. 10 parts of polymer conductive polyaniline;

[0036] 6. 210 parts of weather-resistant filler combination.

[0037] The raw material components and parts of the weather-resistant filler combination are:

[0038] Precipitated barium sulfate 140 parts

[0039] Mica powder 28 parts

[0040] 42 parts of wollastonite;

[0041] 7. Auxiliary combination 29 parts;

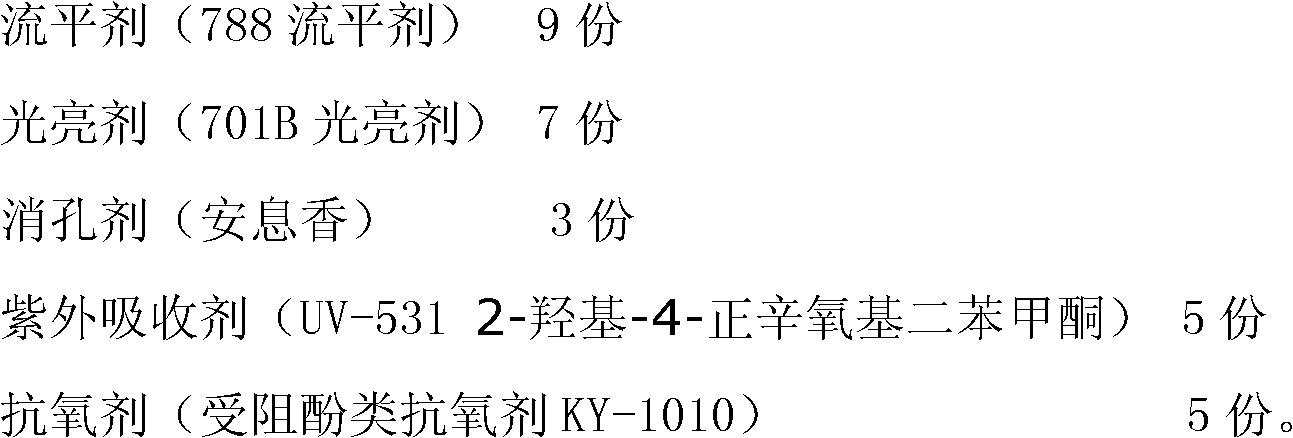

[0042] The raw material components and parts of the additive combination are:

[0043]

[0044] The preparation method is:

[0045] Add the above-mentioned materials to a high-speed mixer, dry mix them and then add them to an extruder, melt, knead, cool, and tablet at an extrusion temperature...

Embodiment 2

[0047] A weather-resistant heavy-duty anti-corrosion powder coating, its raw material composition and weight are:

[0048] 1. GEST-5080 hydrogenated bisphenol A epoxy resin 500 parts;

[0049] 2. 70 parts of amine curing agent;

[0050] 3. 1 part of imidazole;

[0051] 4. 80 parts of conductive zinc powder;

[0052] 5. 20 parts of polymer conductive polyaniline;

[0053] 6. Weather-resistant filler combination 240 parts

[0054] The raw material components and parts of the weather-resistant filler combination are:

[0055] Precipitated barium sulfate 160 parts

[0056] Mica powder 32 parts

[0057] 48 parts of wollastonite;

[0058] 7. Auxiliary combination 29 parts;

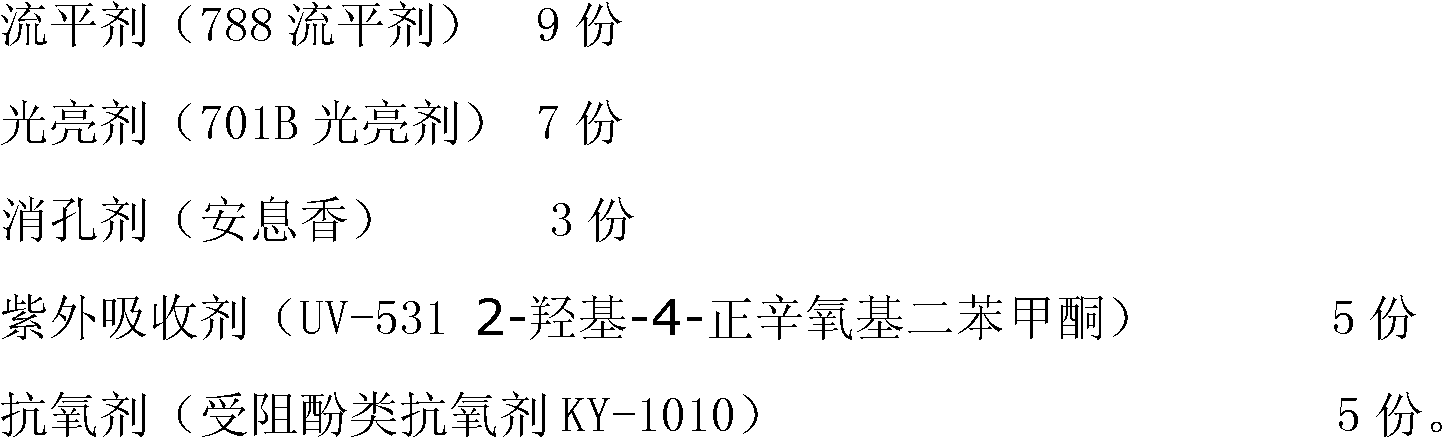

[0059] The raw material components and parts of the additive combination are:

[0060]

[0061] The steps of the preparation method of this embodiment are the same as in Example 1.

[0062] The composition and function of each raw material are described below:

[0063] 1. The present invention abando...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com